Rack for pressurized gas bottles

a pressurized gas and bottle technology, applied in bottle cupboards, bottle transportation, domestic applications, etc., can solve the problems of unresolved structural integrity of the rail itself, explosions can occur, and the gas release can be dangerous, so as to reduce the potential for dangerous materials and effectively suppor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

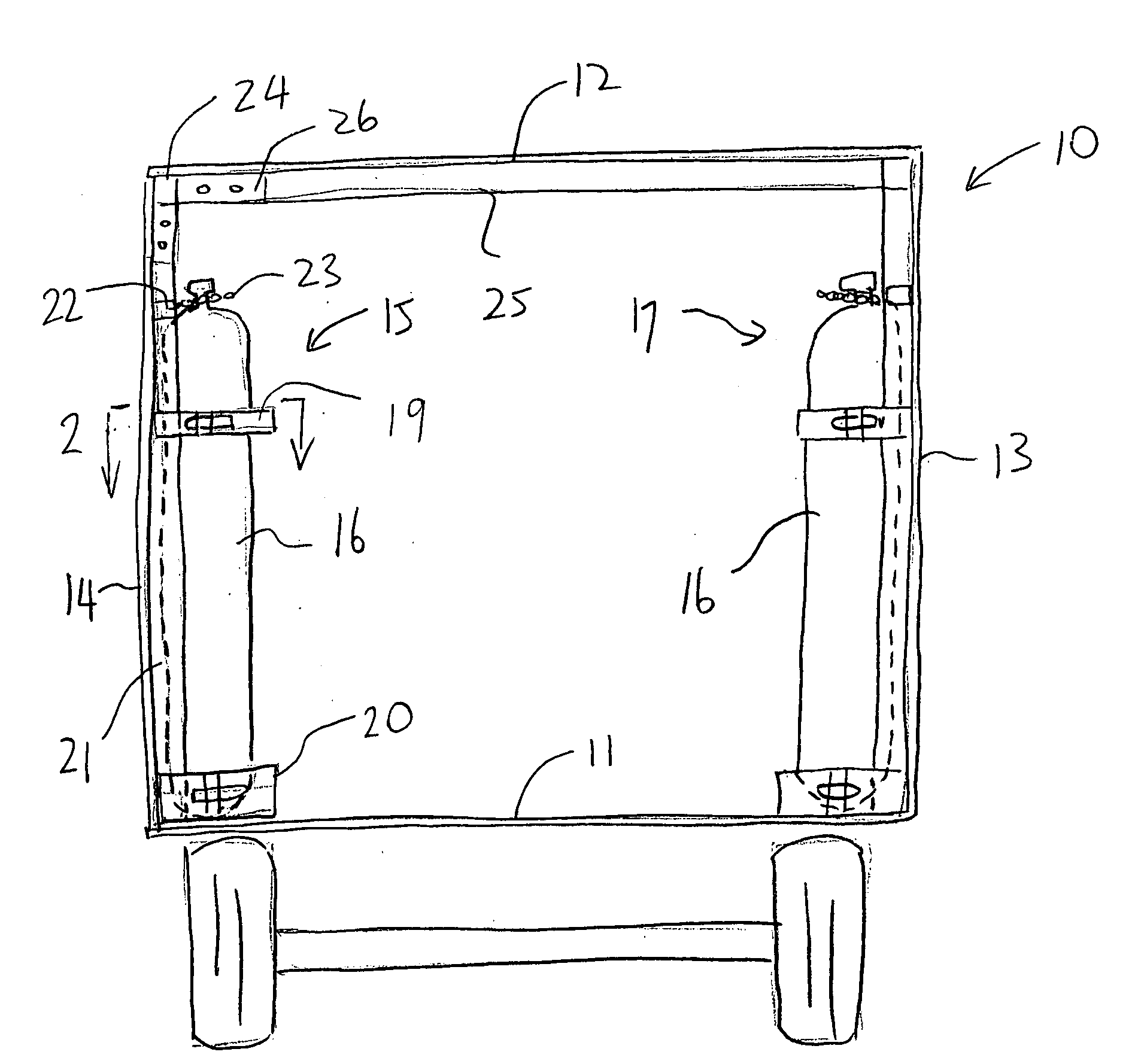

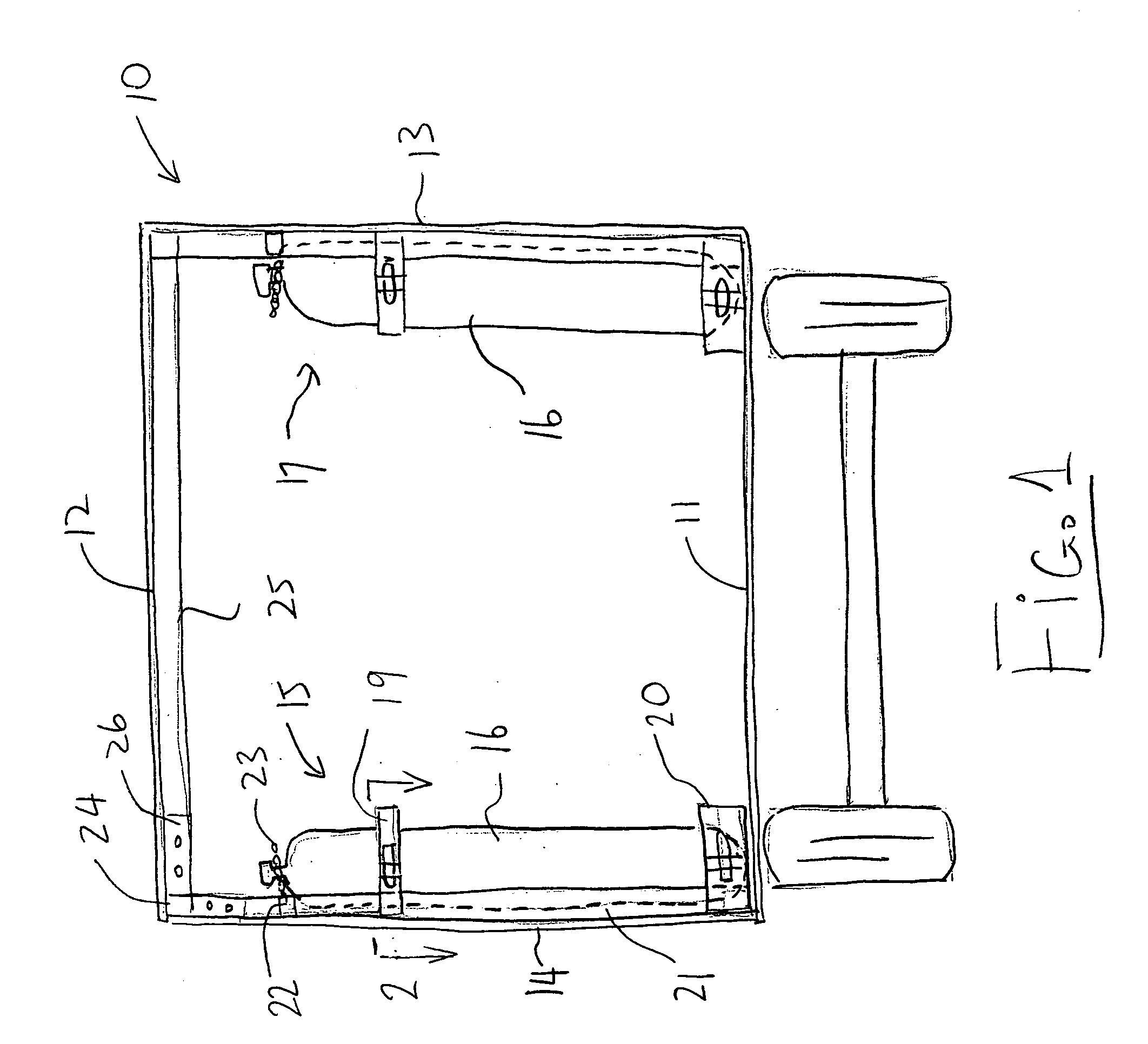

[0060]In FIG. 1 and also shown in FIG. 5 is shown a vehicle 10 which in most cases form a trailer for attachment to a towing vehicle but may be itself a self-propelled vehicle such as a truck. The vehicle includes a rear box having a floor 11, a roof 12 and side walls 13 and 14. The structure of these is shown only schematically since the structure of such vehicles can vary and is well known to a person skilled in the art. In most cases the vehicle will have posts and rails forming a structure for the walls and floor to provide some structural integrity and load bearing capability. However the present arrangement can be used with vehicles of different types having different arrangements for the structural integrity since the device is intended to provide its own structural strength.

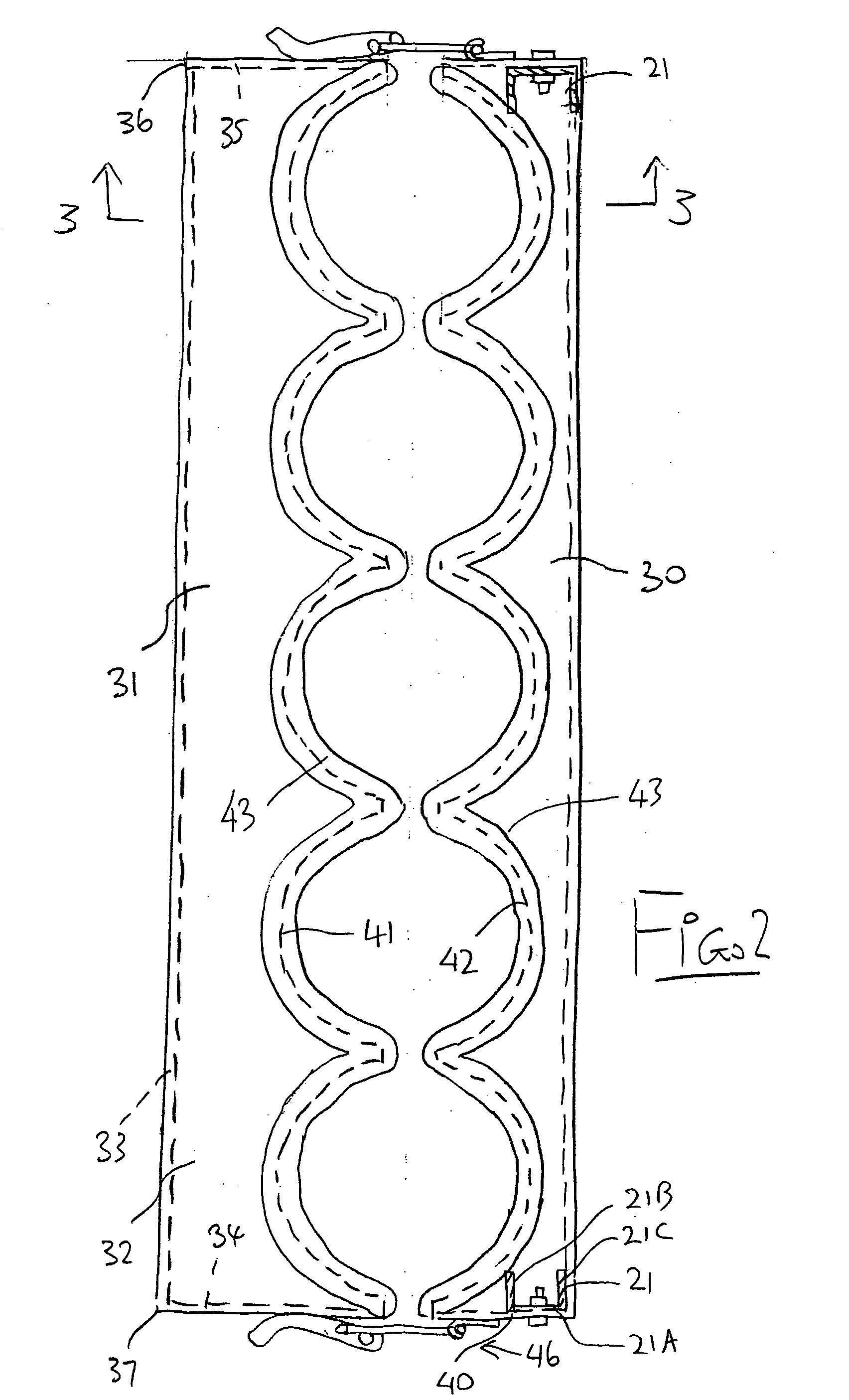

[0061]The apparatus thus comprises a first rack member 15 containing a series of bottles 16 in a row along the side wall 14. The apparatus further comprises a second rack member 17 containing bottles 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com