Foundation system

a foundation system and foundation technology, applied in the field of building foundations, can solve the problems of increasing the chance of foundation failure, affecting the structural integrity of the foundation and the carried structure, and/or producing a non-level foundation, and achieve the effect of easy determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

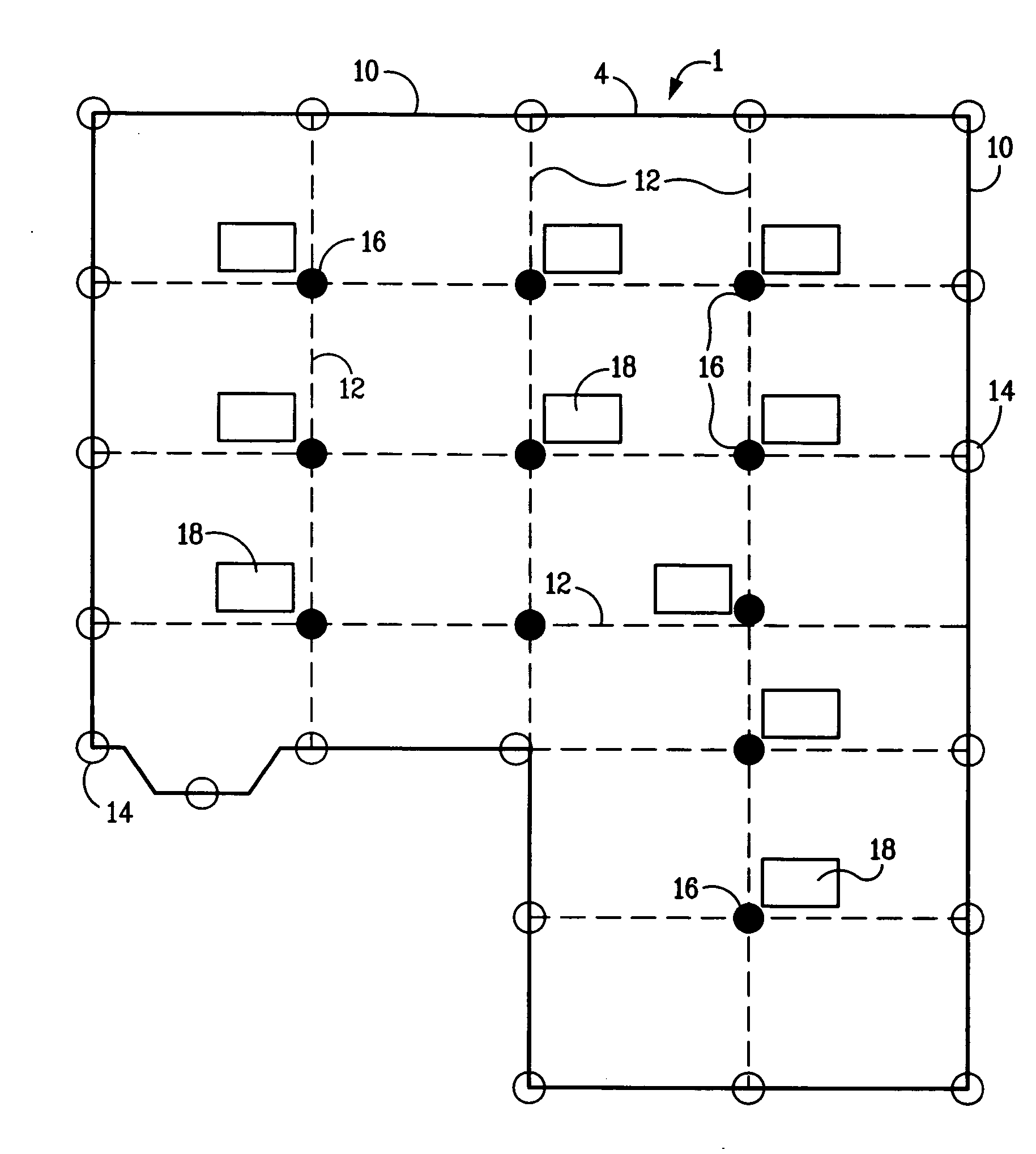

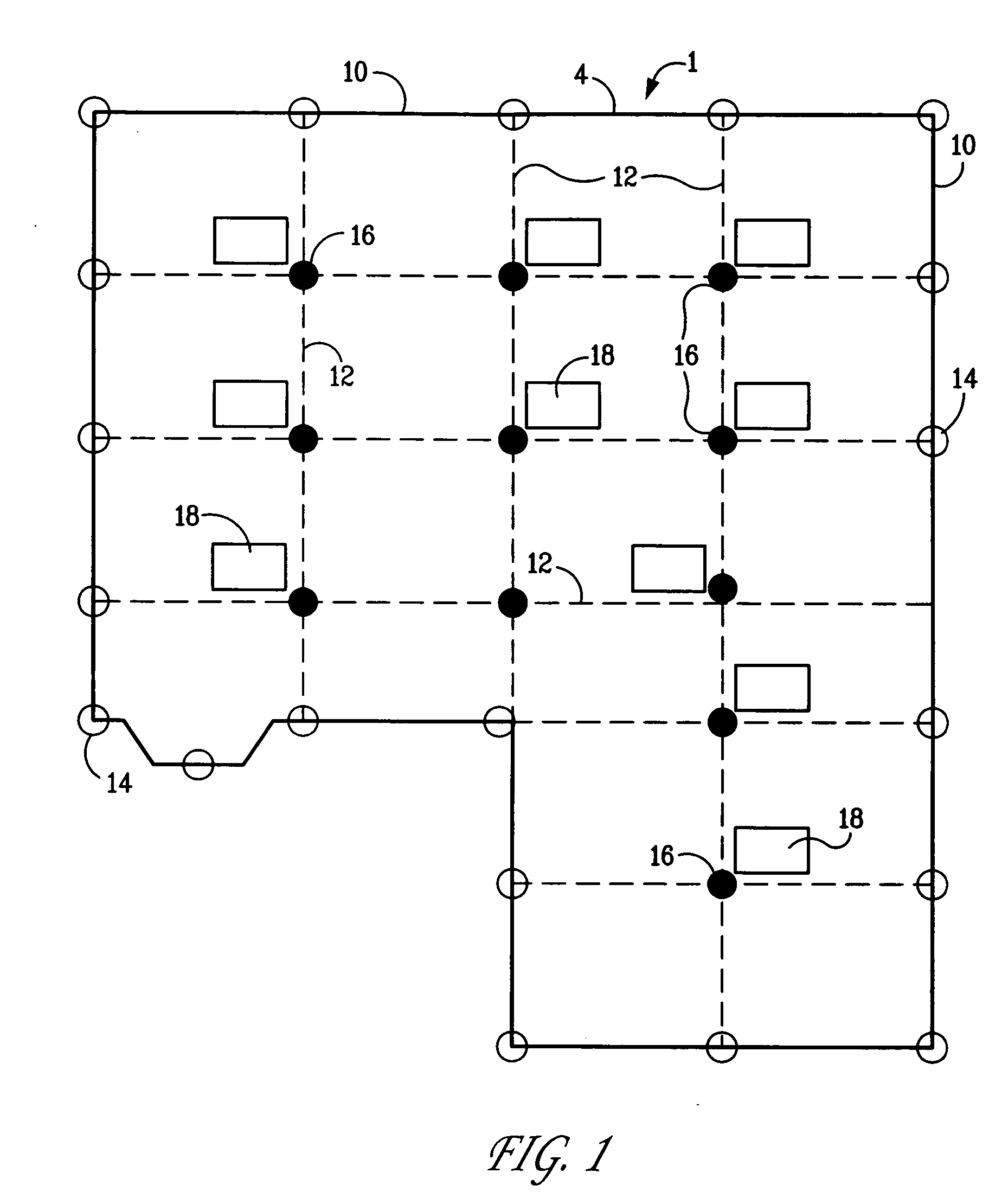

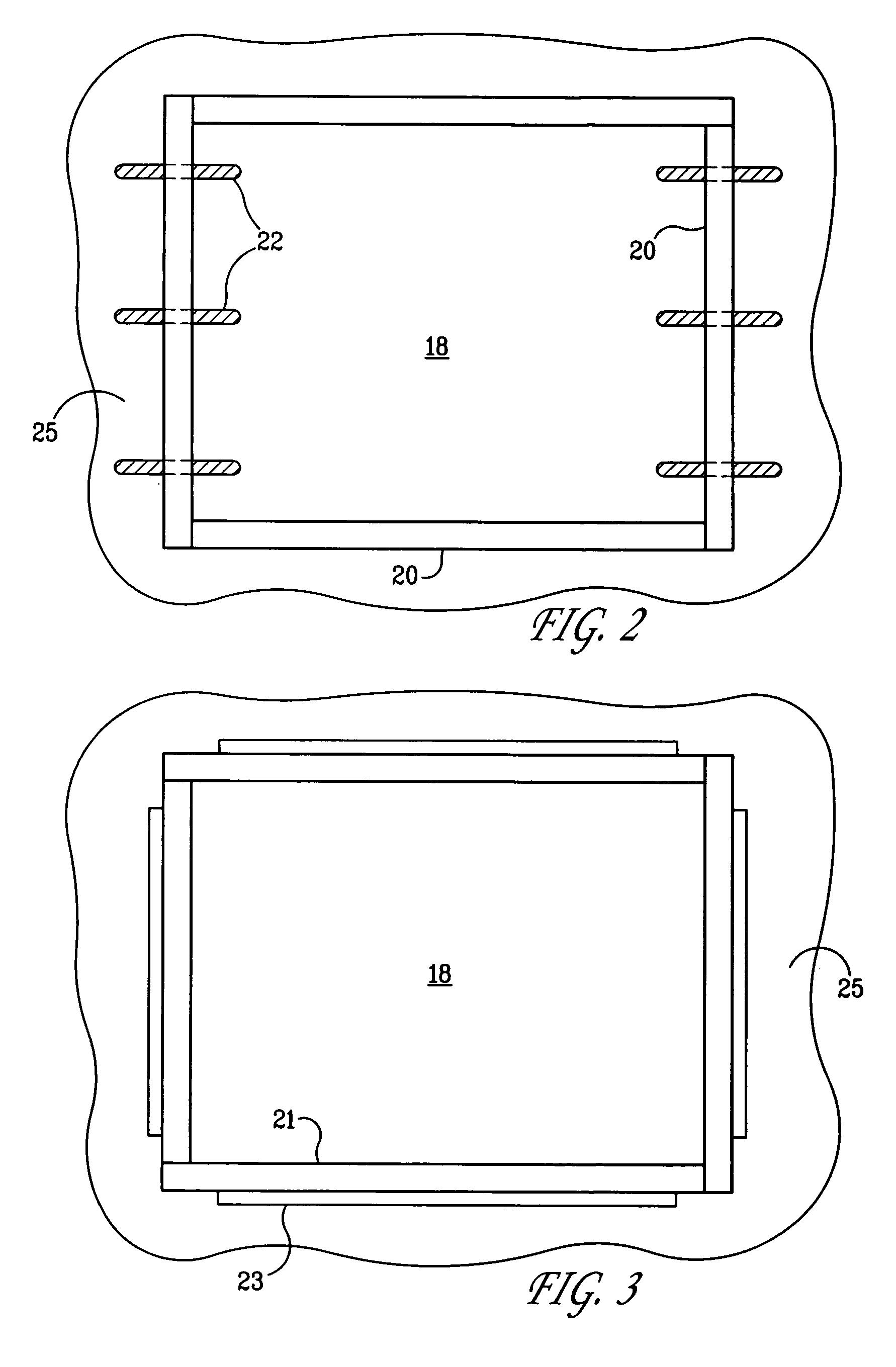

[0024] After on site soil borings are reviewed by a geotech engineer, the Potential Vertical Rise (P.V.R.) values are determined by the geotech. Based on P.V.R. values, the appropriate size void cartons are to be installed under all beams and throughout the entire concrete mat, except directly under the beams adjacent to the formed excess boxes. After an acceptable concrete curing time, a driven pile system is installed through the opening at the preformed box location. After pilings are driven to refusal or to a predetermined load capacity, the pilings are shimmed with various size spacers.

[0025] Prefabricated knockout boxes to form openings are installed on the interior portion of the slab prior to the pouring of the concrete. These boxes are preferably keywayed or doweled to help prevent slippage of the concrete patch after the piling is installed. After the concrete slab is poured and the concrete has had an acceptable curing time, the forms for the boxes are stripped when all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com