Conformable bedding arrangement

a technology of bedding arrangement and conforming, which is applied in the field of bedding materials and arrangements, can solve the problems of time consumption and become a rather time-consuming event, and achieve the effect of saving storage space and tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

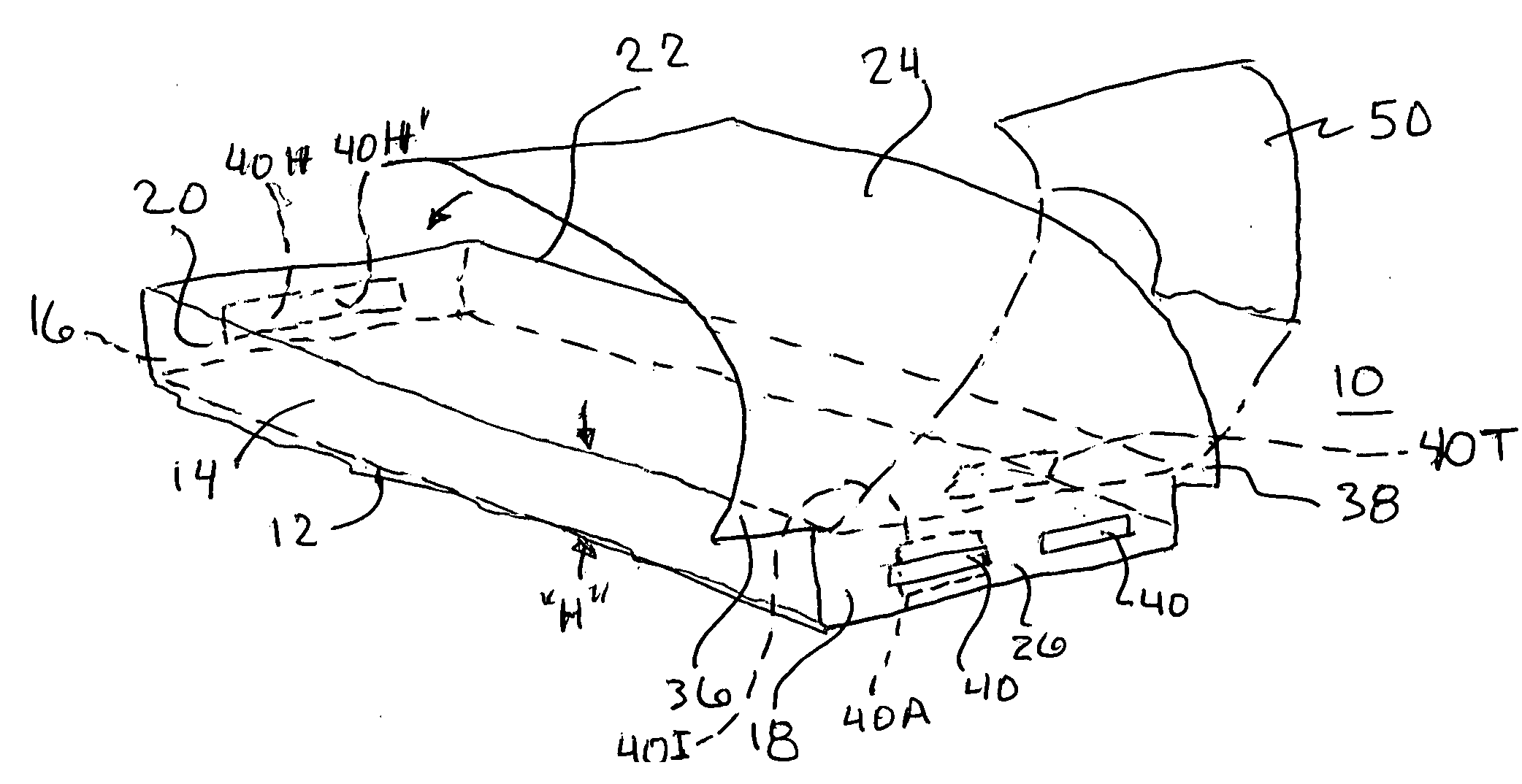

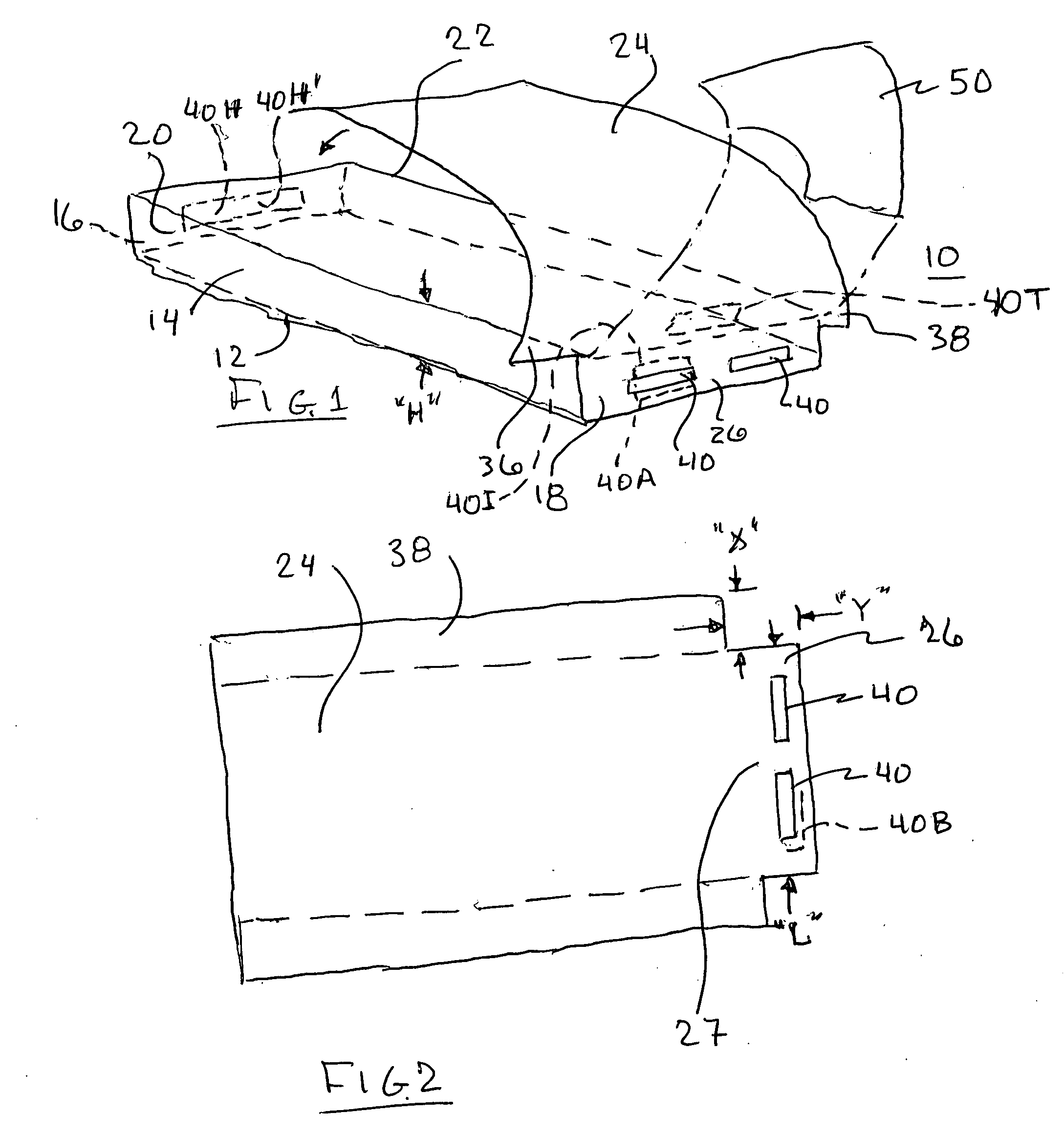

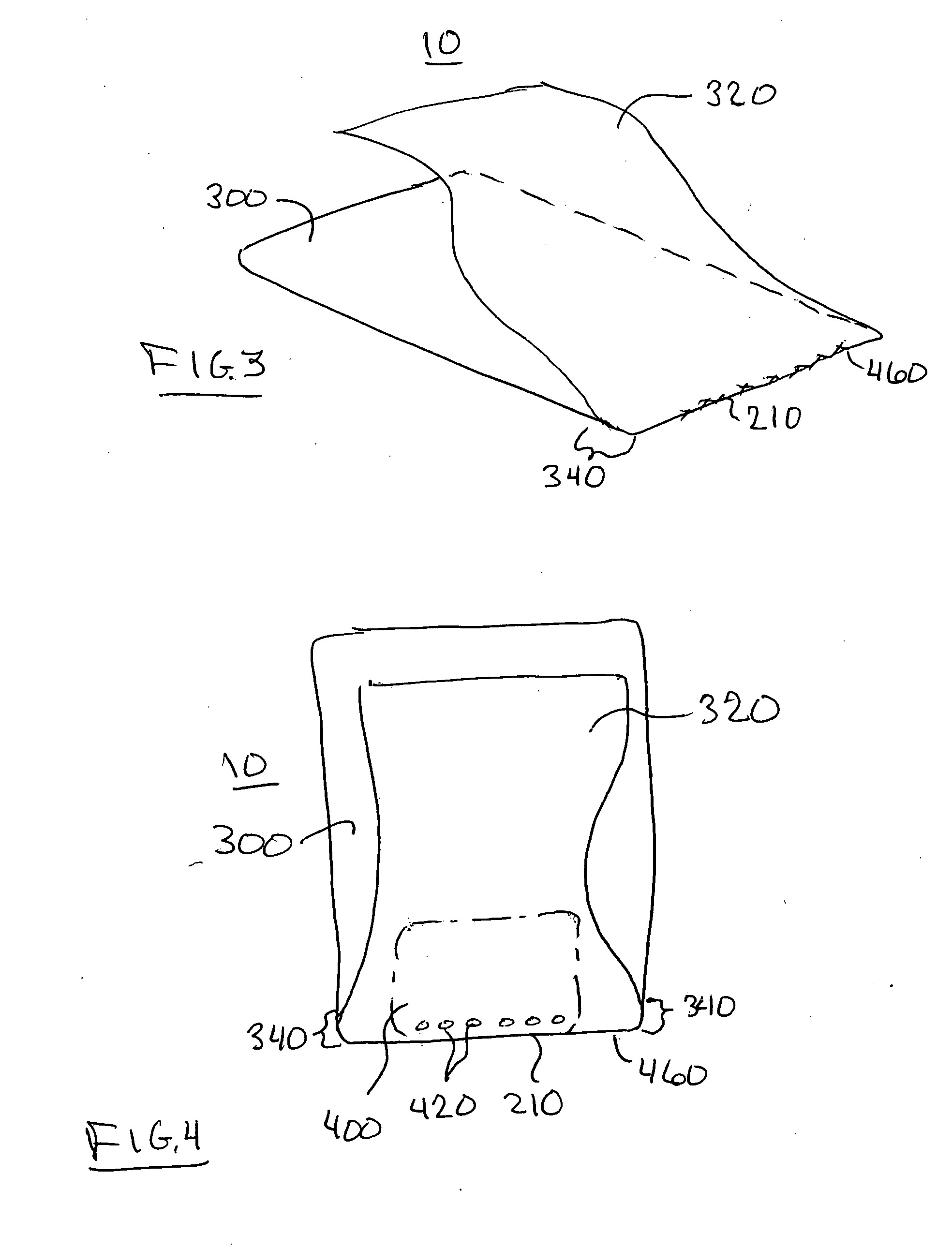

[0028] Referring now to the drawings in detail, and particularly to FIG. 1, there is shown the present invention which comprises an improved bedding sheet construction assembly 10 to be utilized in the covering over a mattress 12 and in the making of a bed as may be found in a typical home, motel, hotel or hospital. The mattress 12 of a bed typically comes in sizes such as for example, standard, double, queen, or king size mattresses. Thickness of such mattresses may run for example, about 8 inches to about 16 inches or more.

[0029] A lower or fitted sheet 14 of the bedding sheet assembly 10 shown mated about a a mattress 12 in FIG. 1 conforms generally to the outer perimeter of the mattress 12 to which it is supposed to be placed upon. The “head” and “foot” ends 16 and 18 of the mattress 12 are narrower than either of the “sides”20 and 22 of that mattress 12. The narrow or foot end 18 of a fitted sheet 14 or a regular “flat” sheet is thus narrower than the long side of either side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com