Multi-Position Work Tables

a work table and multi-position technology, applied in the field of furniture, can solve the problems of compulsion of users, undesirable weight and considerable extra cost, and undesirable jack-actuation for many users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

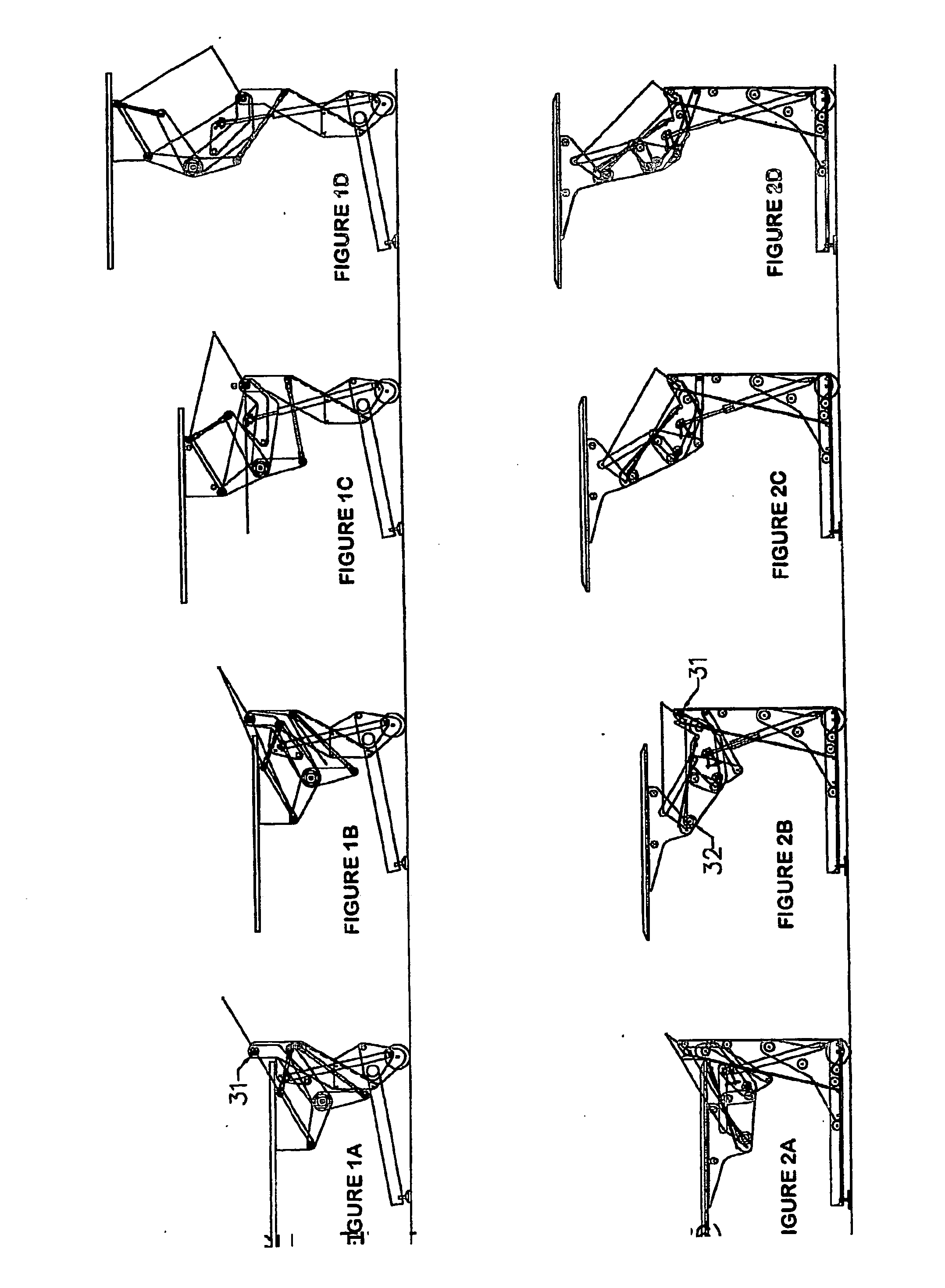

first and second embodiments

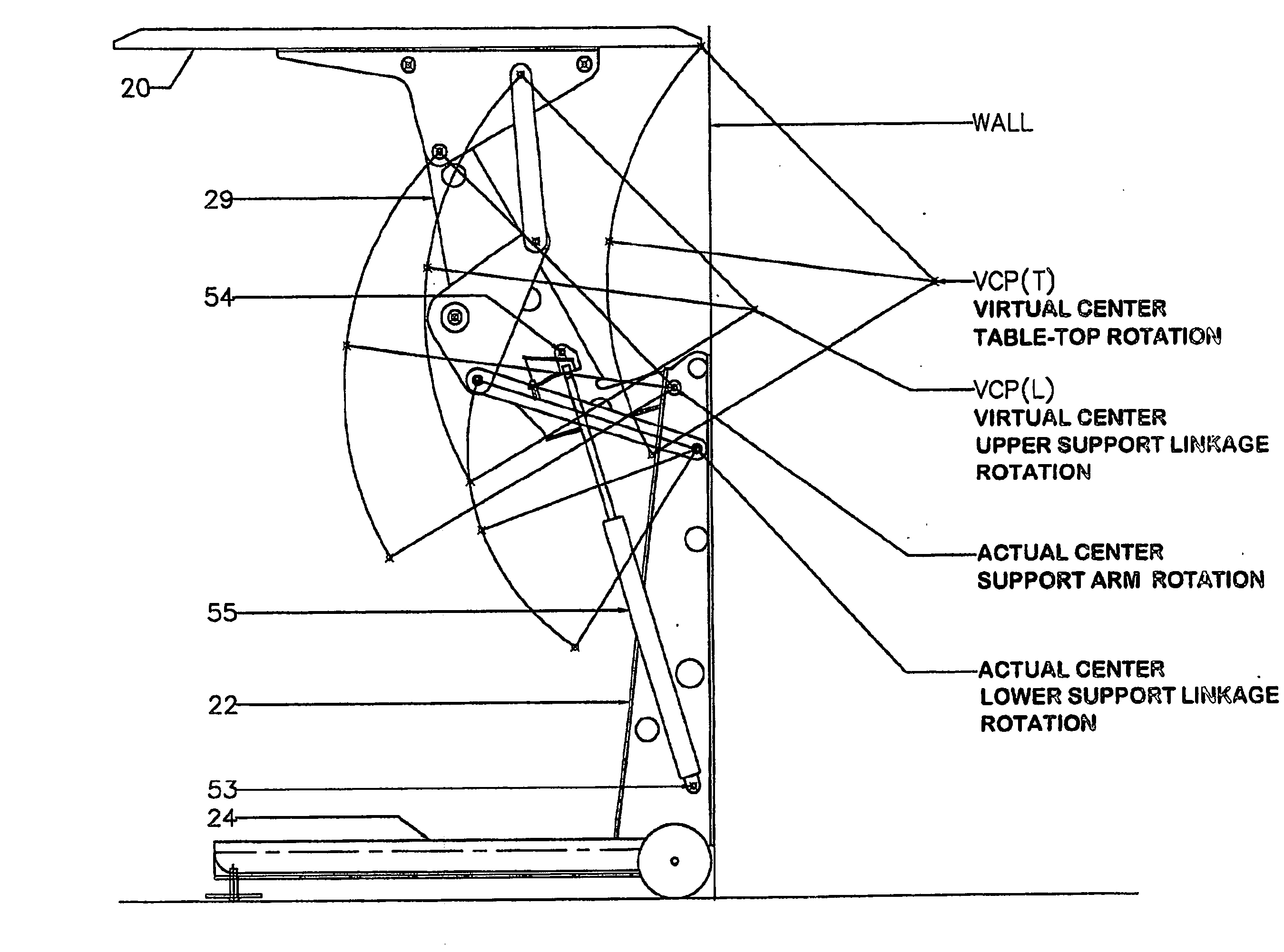

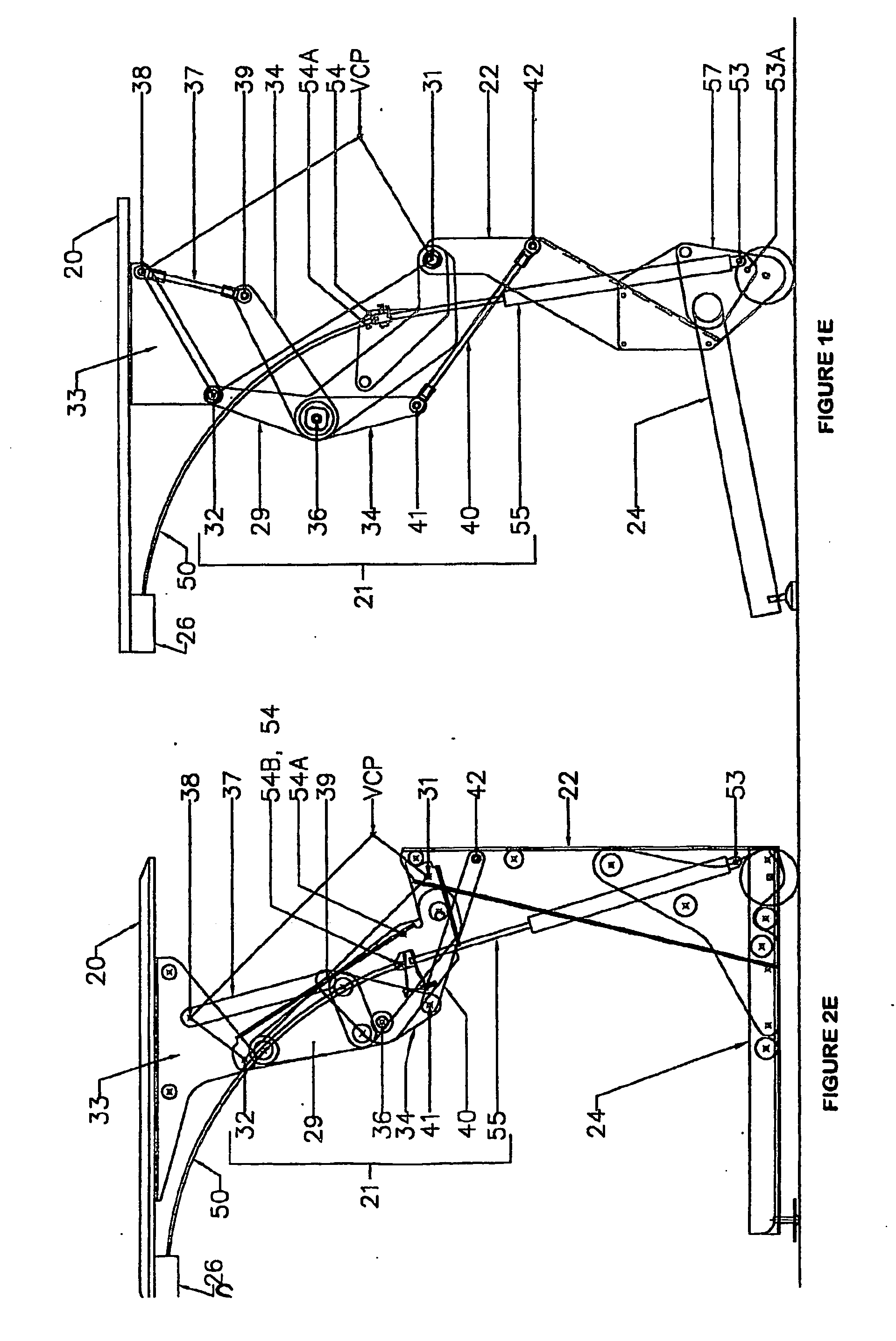

[0045] Comparison of FIGS. 1E and 2E shows that tabletop 20 is supported in both the first and the second preferred embodiments by a pivoted linkage 21, which itself is pivotally mounted on column 22, upstanding from base 24.

[0046] In each embodiment a gas spring piston-cylinder assembly 55 has its ends pivotally connected to column 22 and to linkage 21.

[0047] The pivotally connected components forming linkage 21 are very similar in both the first and the second preferred embodiments. This is confirmed by comparing the exploded views of FIG. 1F and FIG. 2F, where the various comparable components are arrayed side by side in these two FIGURES. The pivoted interconnections of each of these linkage components with the next is clearly shown in the assembled views of FIGS. 1E and 2E, and their articulated movement is shown in FIGS. 3A-3F.

[0048] Thus, for the first embodiment, a central member is the cantilever arm 29, shown to be U-shaped in FIG. 1F, having rear pivot point 31, joinin...

second embodiment

Pivoted Components of Second Embodiment

[0055] As shown in FIGS. 2E and 2F, the same components are connected in much the same fashion in the second preferred embodiment as they are in the first preferred embodiment, and the pivoting articulation of these components of linkage 21 is shown in the six successive diagrams of FIGS. 4A through 4F, and in FIGS. 6, 7 and 8.

[0056] Accordingly, the foregoing description of the linkage components of the first preferred embodiment is equally applicable to those of the second, and the corresponding components and pivot points have been given the same reference numerals in the FIGURES.

[0057] Cantilever arm 29 is V-shaped and bell crank 34 is generally triangular, but these do not change their function or cooperation.

Operation of the Gas Spring Piston-Cylinder

[0058] When the gas spring piston-cylinder 55 is ideally pressurized for the total weight of the tabletop, opening the control valve 48 will allow the tabletop to “float” with minimum han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com