Bullet-loading structure of toy gun

a toy gun and shell technology, applied in the field of shell-loading structure of toy guns, can solve the problems of reduced shooting performance, insufficient sucked gas, and reduced shooting performance, so as to improve the shooting performance of toy guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The above-mentioned features and advantages of this invention, and the manner of attaining them, will become more apparent and the invention will be better understood by reference to the following description of embodiments of the invention taken in conjunction with the drawings.

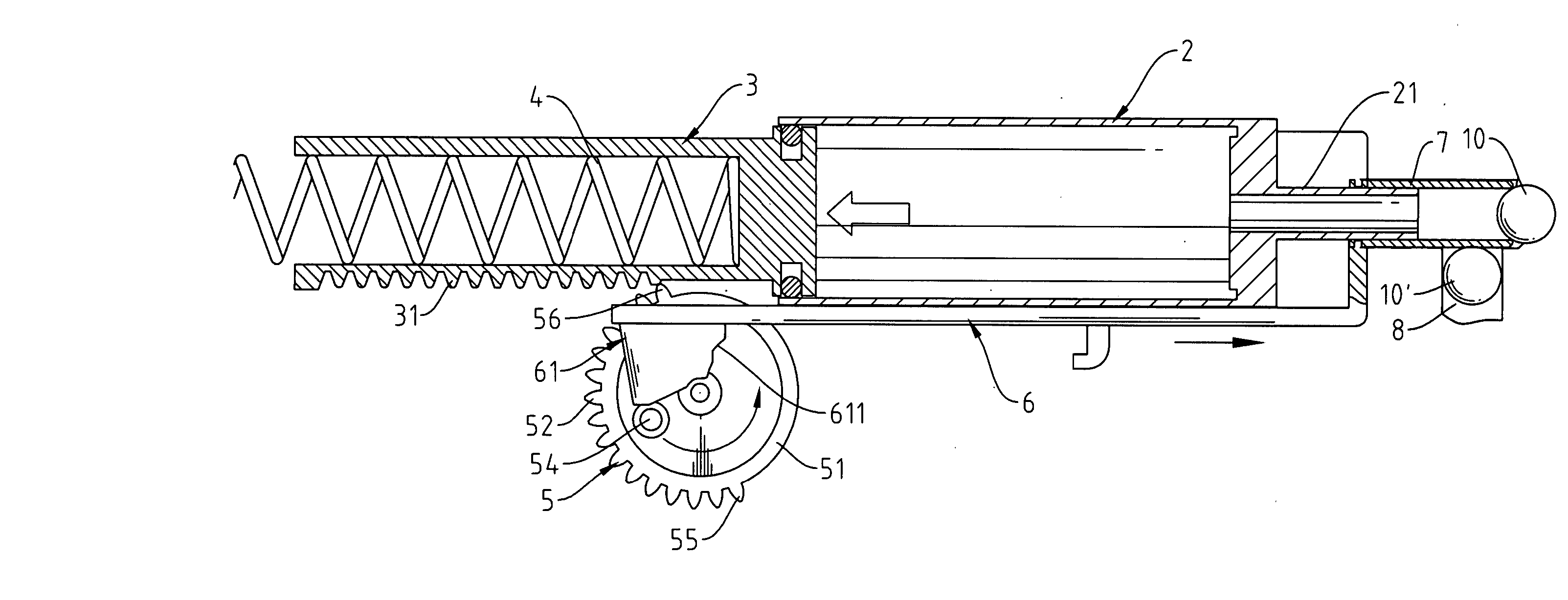

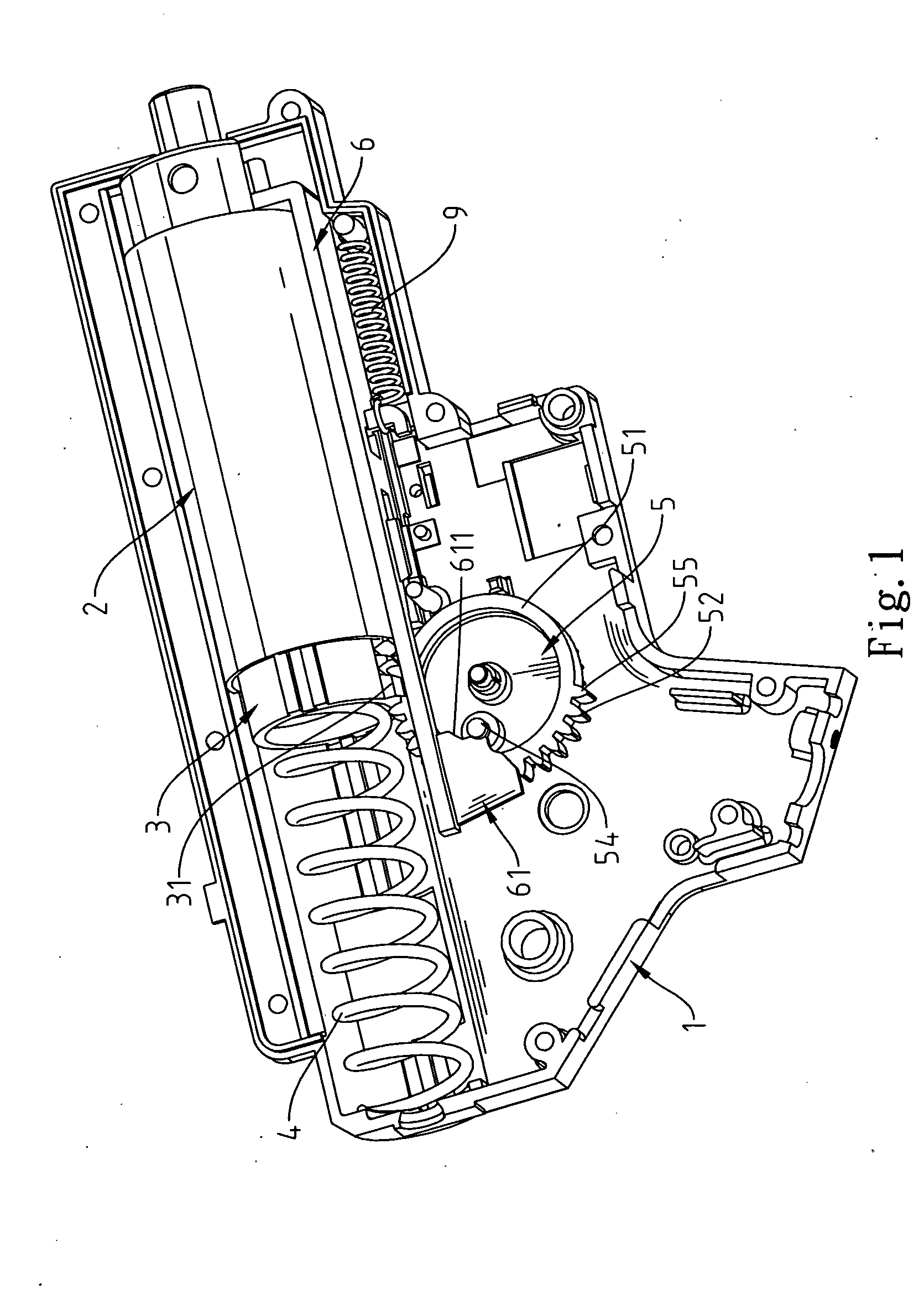

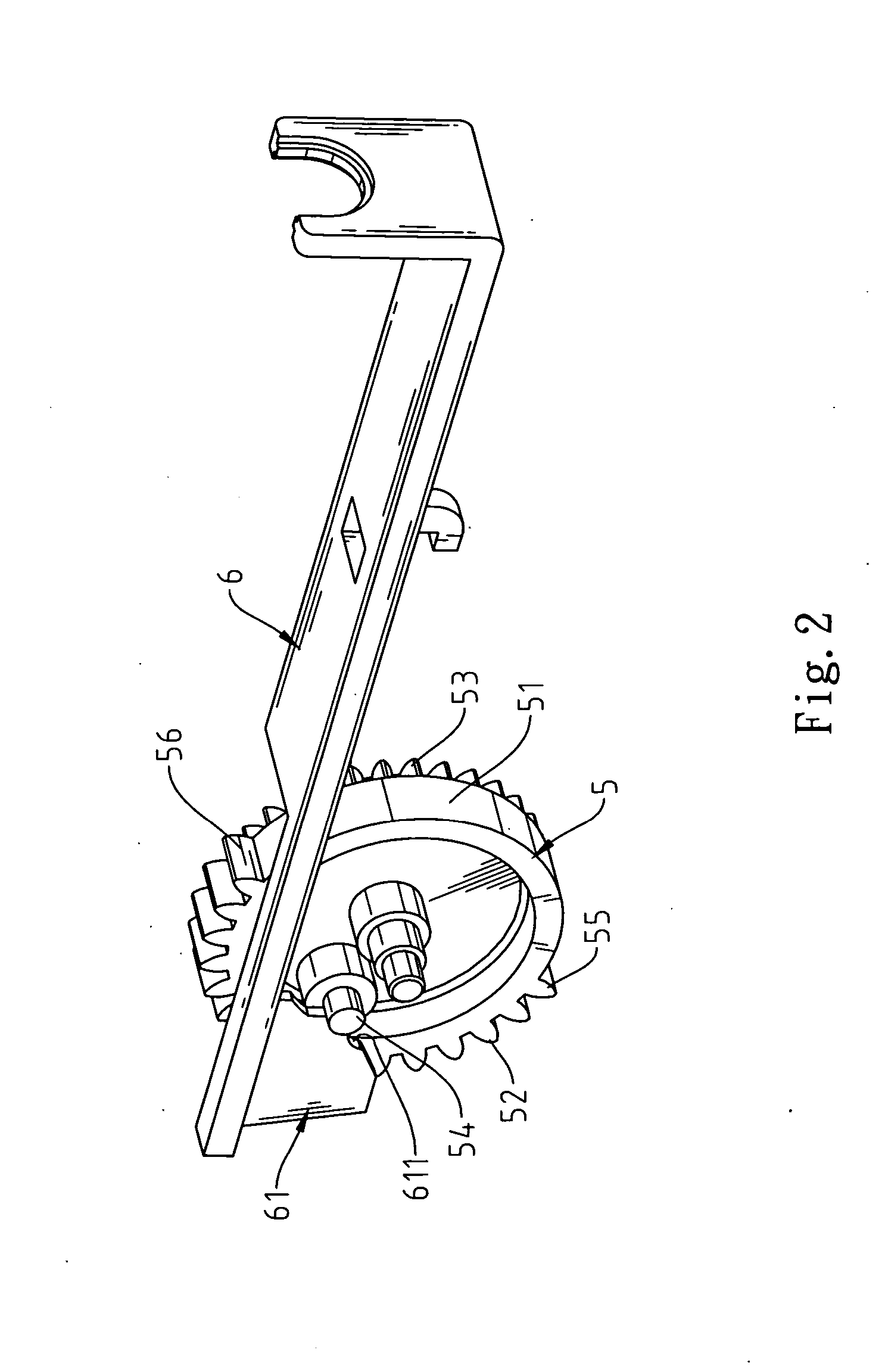

[0018] Referring to FIG. 1 and FIG. 2, a piston 3 is slidable in a cylinder 2 in a gun body 1 of the present invention and a compressible spring 4 is located between the piston 3 and a rear end of the gun body 1. The backward shifting of the piston 3 in the cylinder 2 causes the suction of the gas. Besides, the gas is compressed immediately when the piston 3 is shifted forward by the resilience force provided by the recovered compressible spring 4, which is compressed previously, such that the compressed gas is exhausted from a gas outlet 21 of the cylinder 2 for shooting a bullet.

[0019] The power for shifting the piston 3 backward is supplied in accordance with the following description. A rack 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com