Method of forming a structural component having a NANO sized/sub-micron homogeneous grain structure

a technology of nano-sized/sub-micron grain structure and structural component, which is applied in the field of manufacturing process of structural components, can solve the problems of complex die structure and components, high cost of construction using such billets, and known dies having a detrimental operation, so as to reduce friction between workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

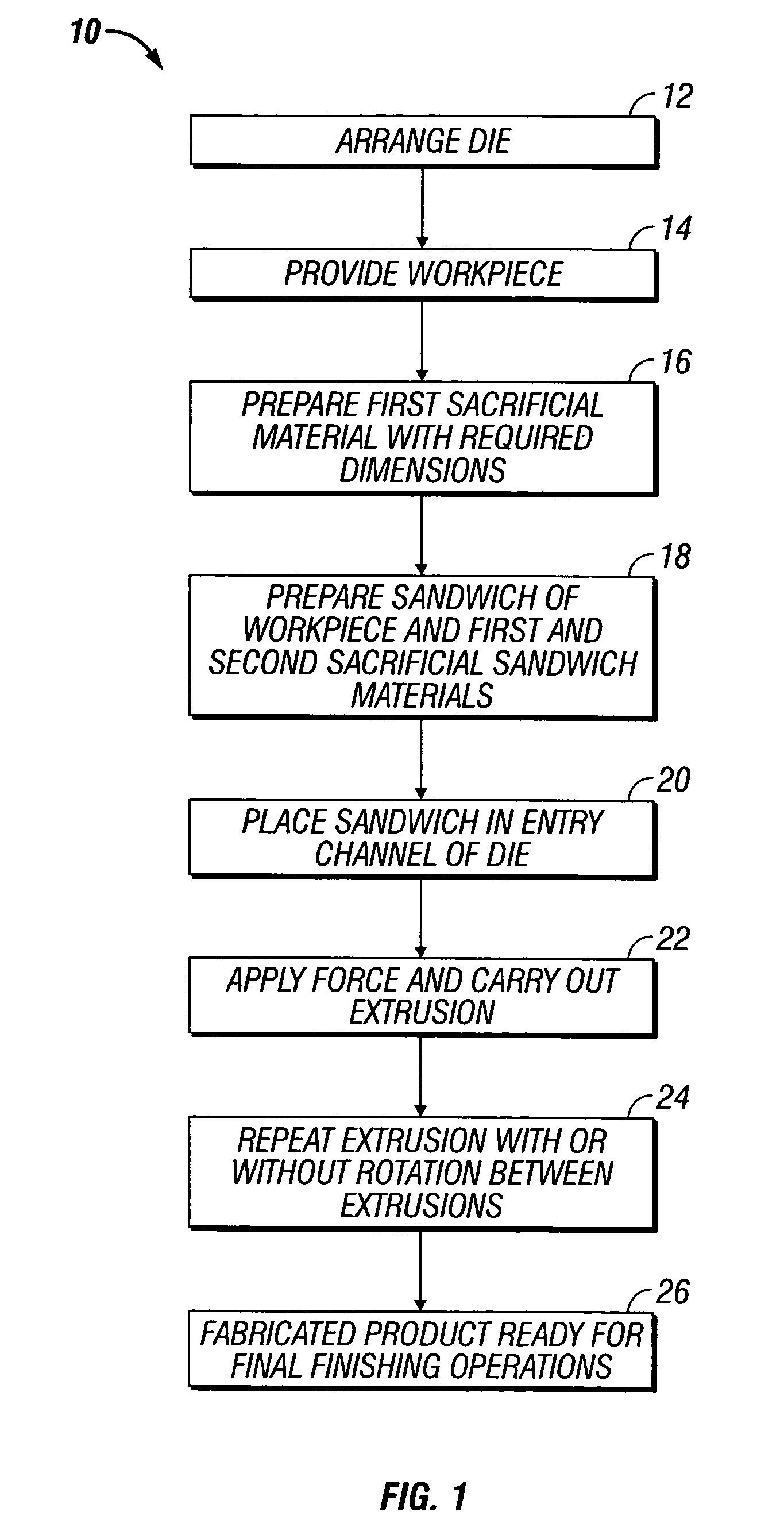

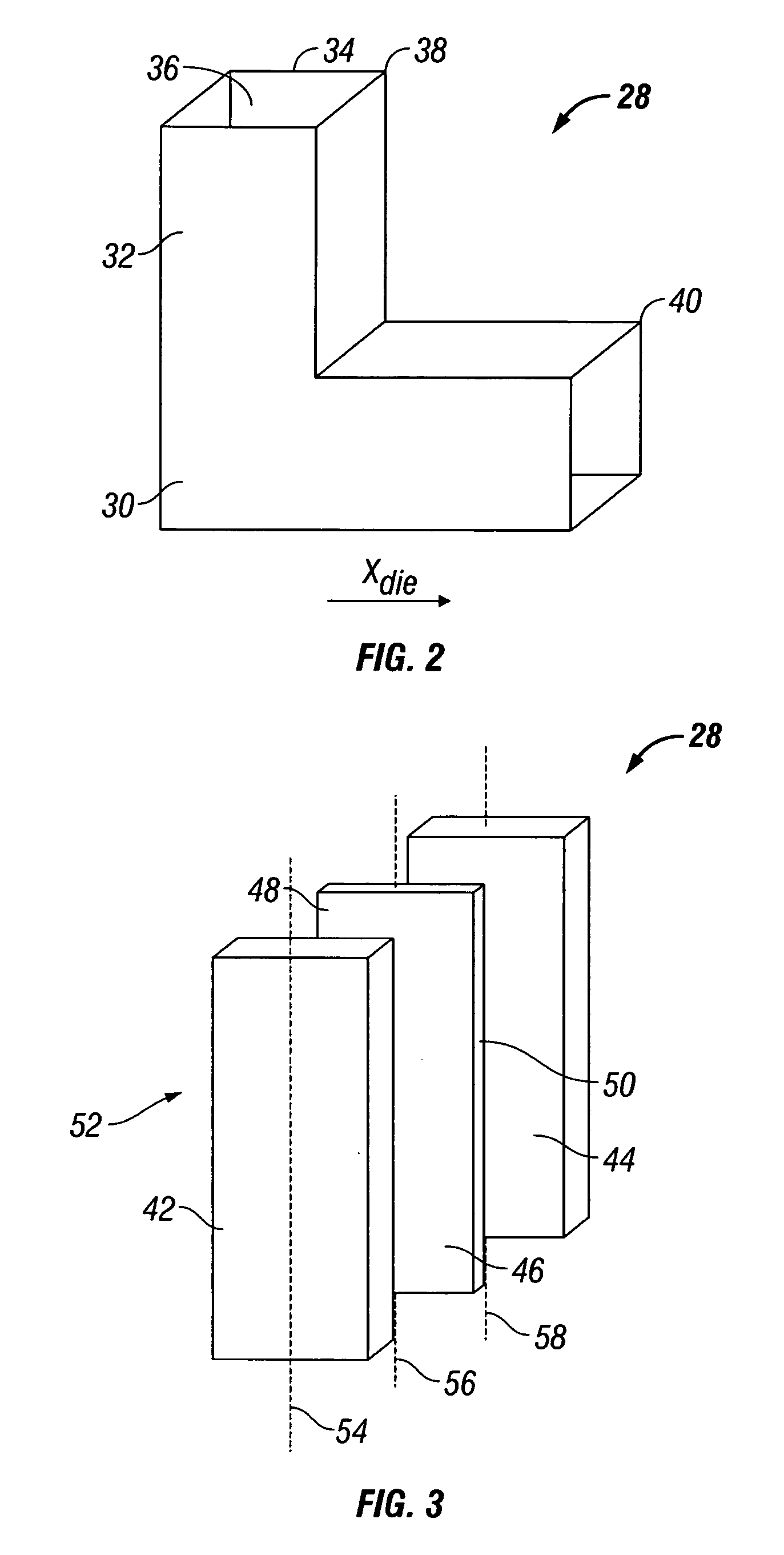

[0039] Reference should be made to the drawings where like reference numerals refer to similar elements throughout the various figures. The fabrication process of the present disclosure controls a microstructure of a work piece material resulting from a deformation of the work piece material. The fabrication process uses a first sacrificial material and, in some embodiments, a second sacrificial material, to reduce friction between a die and the work piece, and thus form a homogenous nano / sub micron sized grains in the work piece material or work piece.

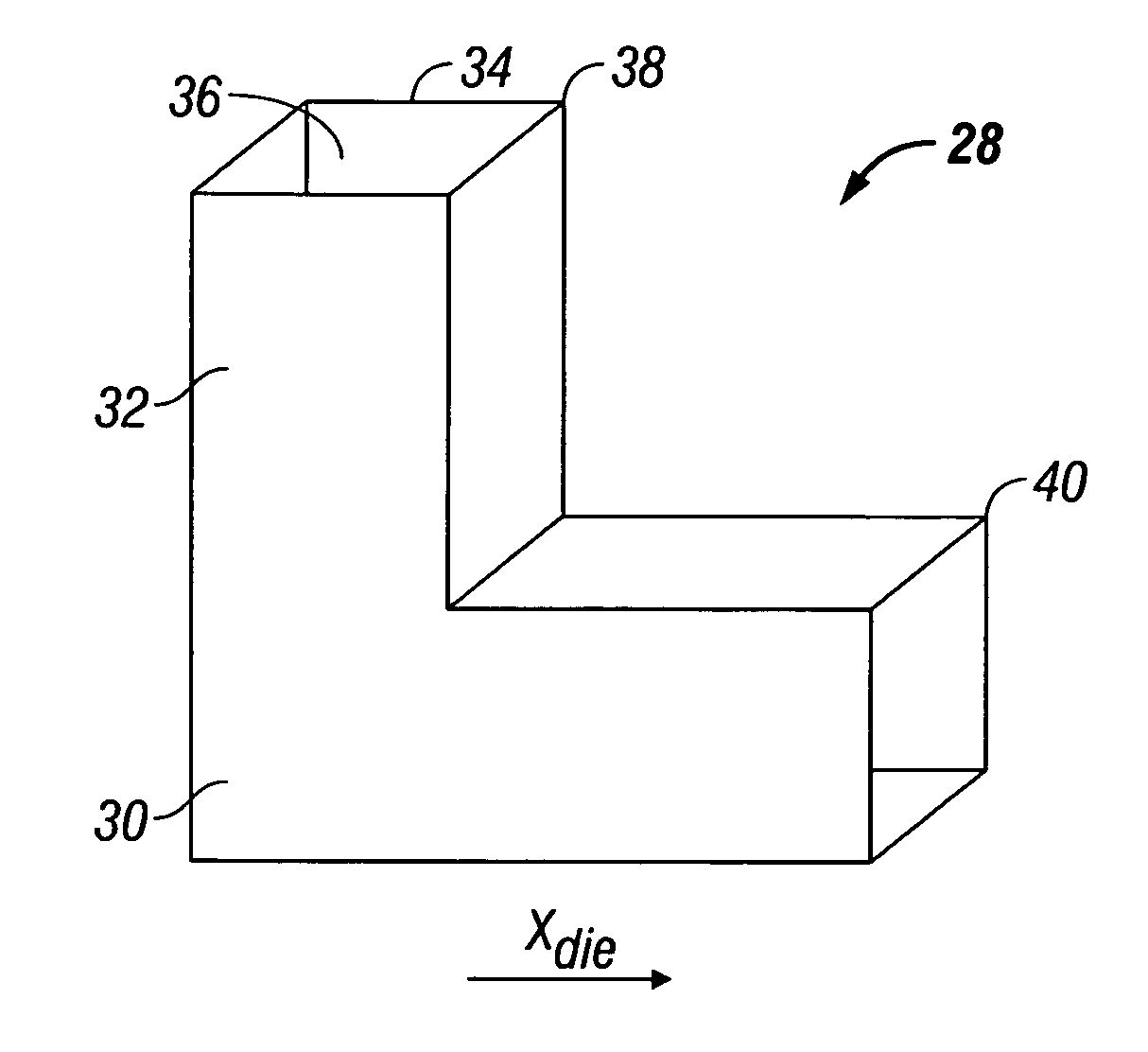

[0040] Referring now to FIG. 1, there is shown a process flow chart of the fabrication method 10 of the present disclosure. The method 10 has the first step 12 of arranging the die. Thereafter, the method proceeds to step 14. At step 14, the method has the step of providing a work piece in the die. The work piece is defined as the material that will undergo the plastic deformation in order to result in a controlled microstructure. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com