Suture material for pneumatic suture instrument

a suture material and suture technology, applied in the field of suture instruments, can solve the problems of additional tissue insult and the need to reinsert, and achieve the effect of facilitating the separation of the delivered strand and entrainment of the sutur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

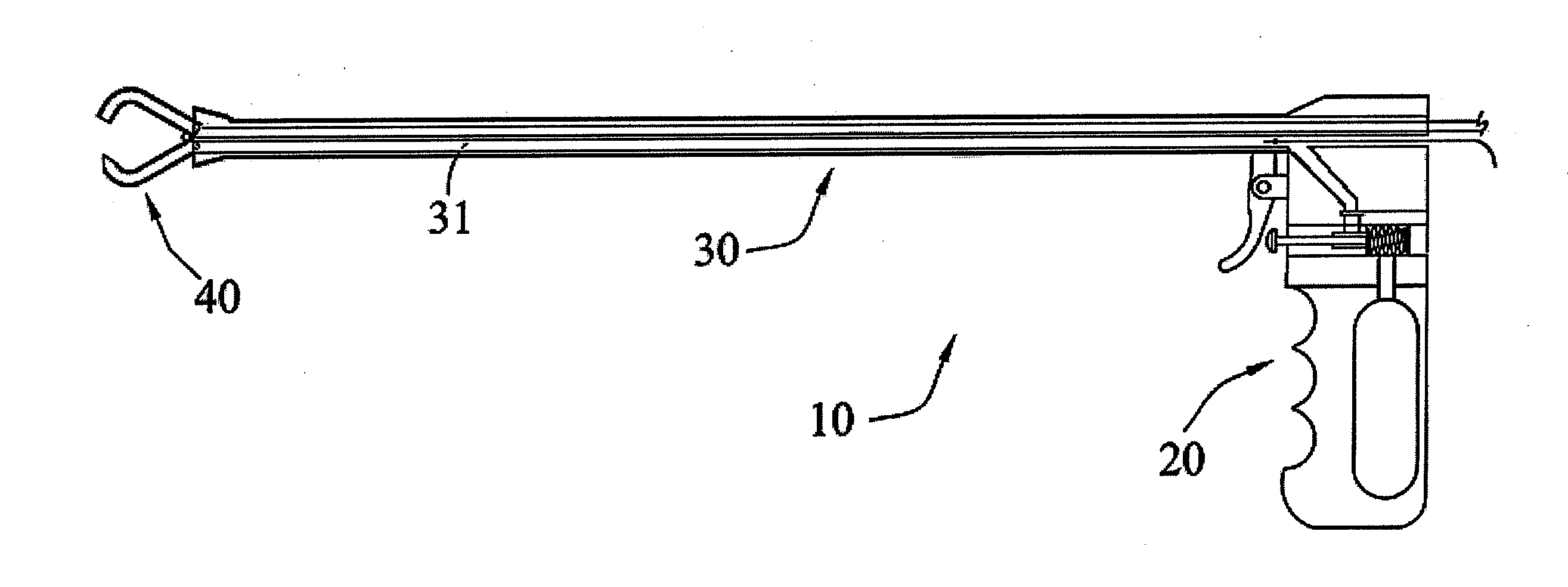

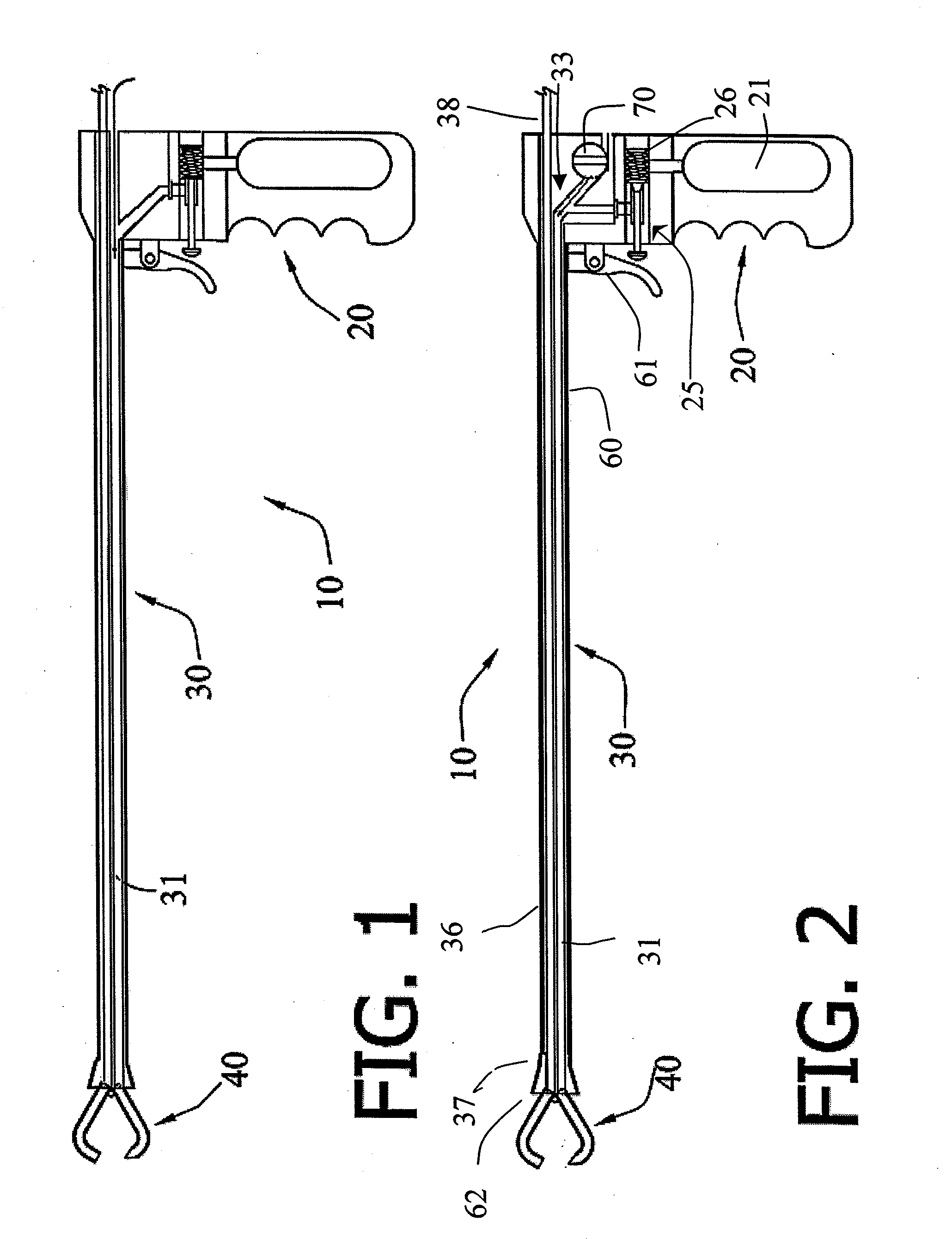

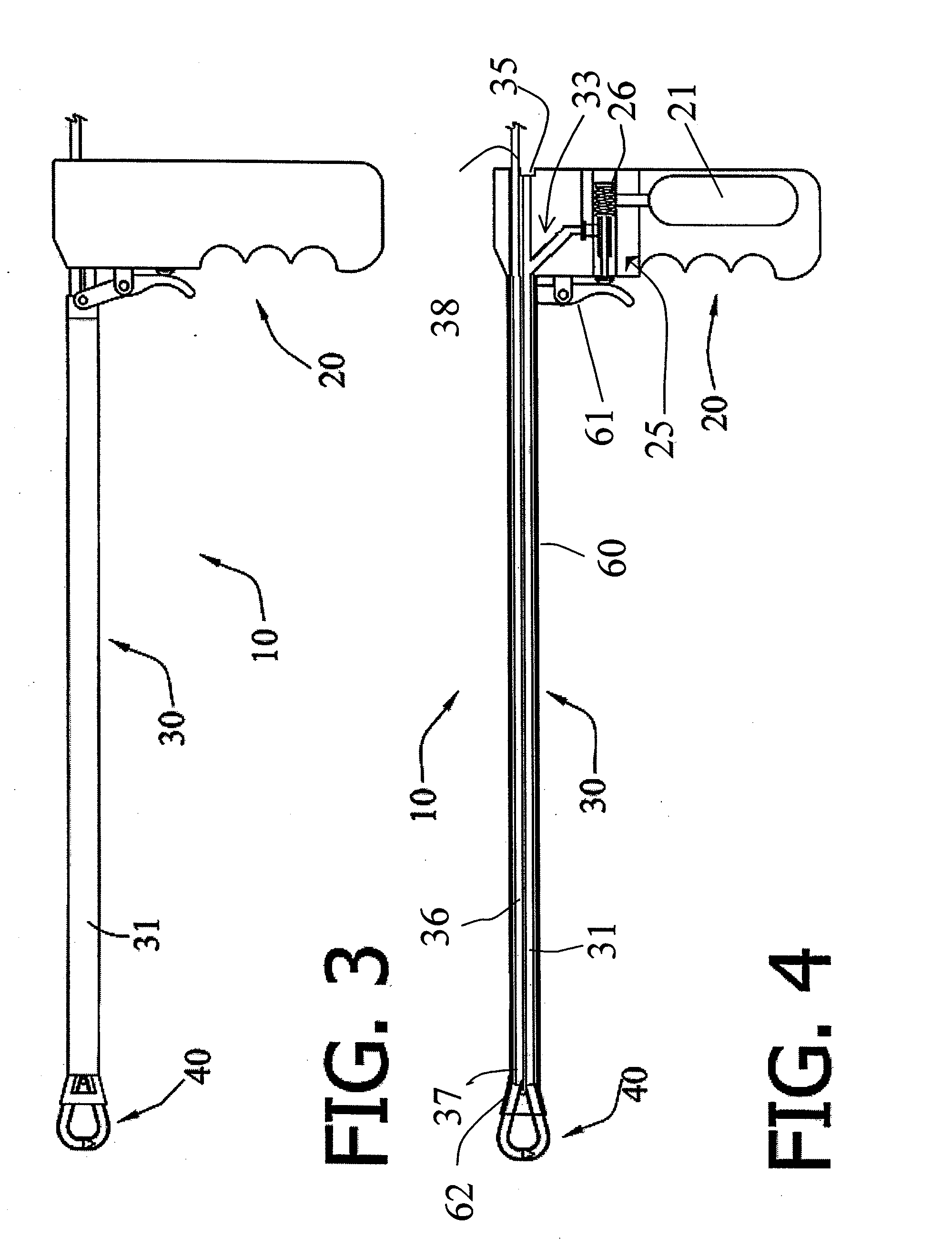

[0043] In reference to the drawings, the suture instrument 10 of the present invention comprises a handle portion 20, an elongated tubular member 30 extending from handle portion 20 and a hollow tissue penetrating needle 40 located at an end of elongated tubular member 30 distal handle portion 20. The length of elongated tubular member 30 is selected to correspond with a desired penetration depth within a body to reach the tissues to be joined 11 by a suture 50. The tissues to be joined 11 will also be referred to herein as site of interest. As is well known in the art, a cannula 12, such as that depicted in FIG. 18, is often used to retract the tissues at the entry incision 13 and improves access to the site of interest 11 by retracting the tissues overlying the site of interest 11. Cannula 12 will also perform a protective role for the overlying tissues by preventing undesirable instrument contact with the same. Accordingly, the length of elongated tubular member 30 must also acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com