Motor and motor integrated pump with the motor

A motor and motor-driven technology, applied in the direction of pumps, pump devices, mechanical equipment, etc., can solve the problems of position deviation, winding and wiring operation obstacles, etc., and achieve the effect of reducing manufacturing costs, shortening takt time, and easy wiring operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

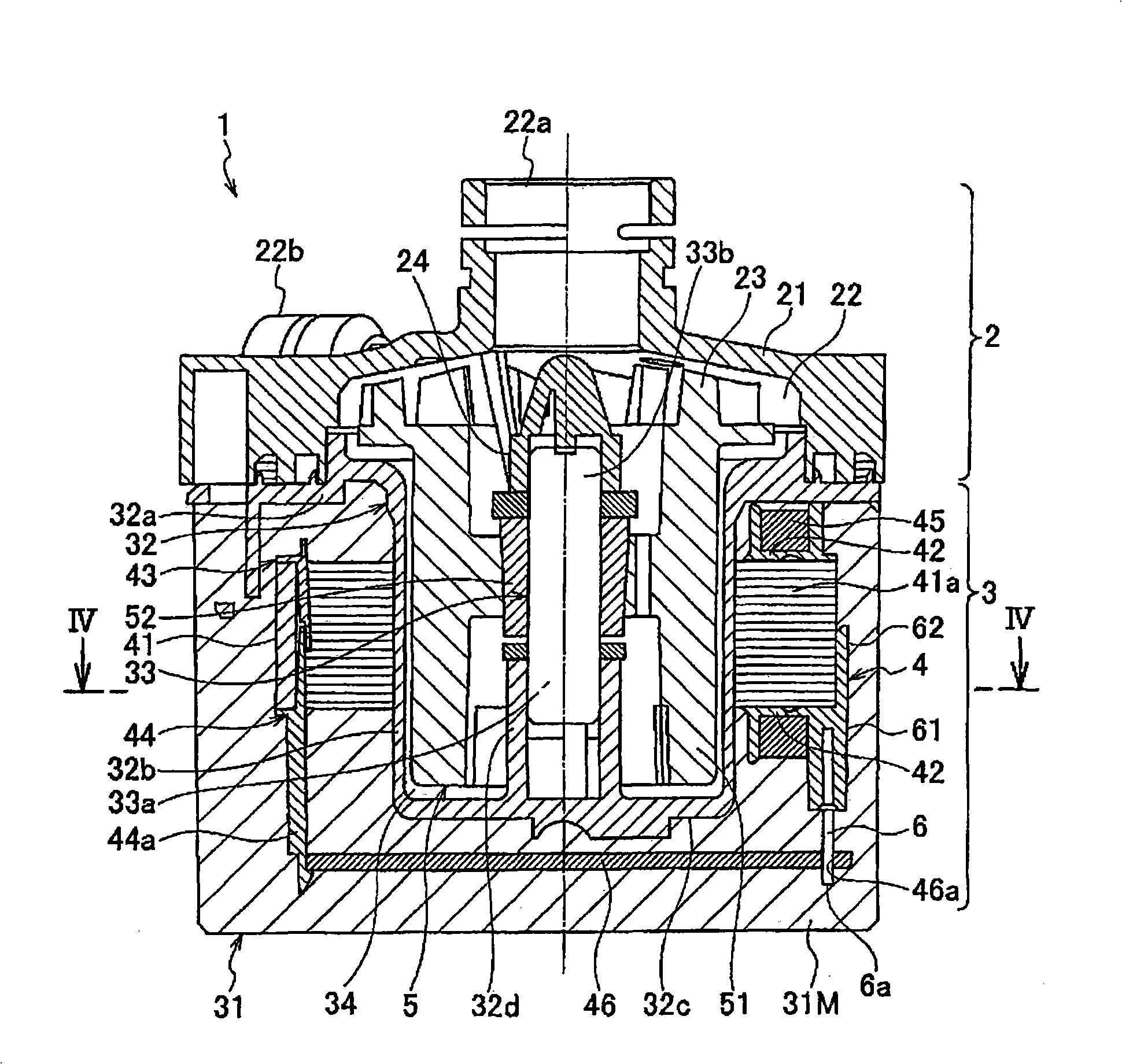

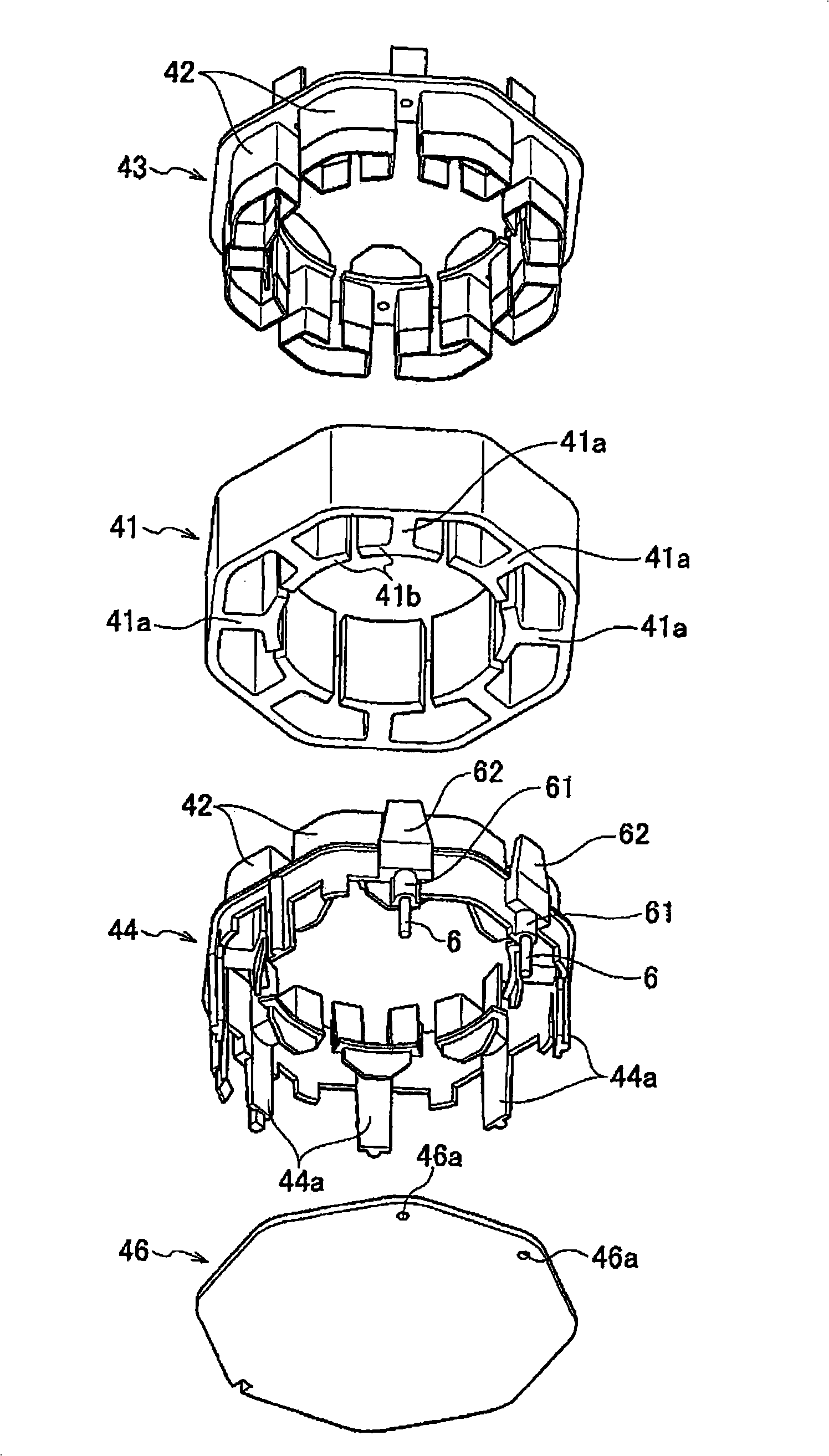

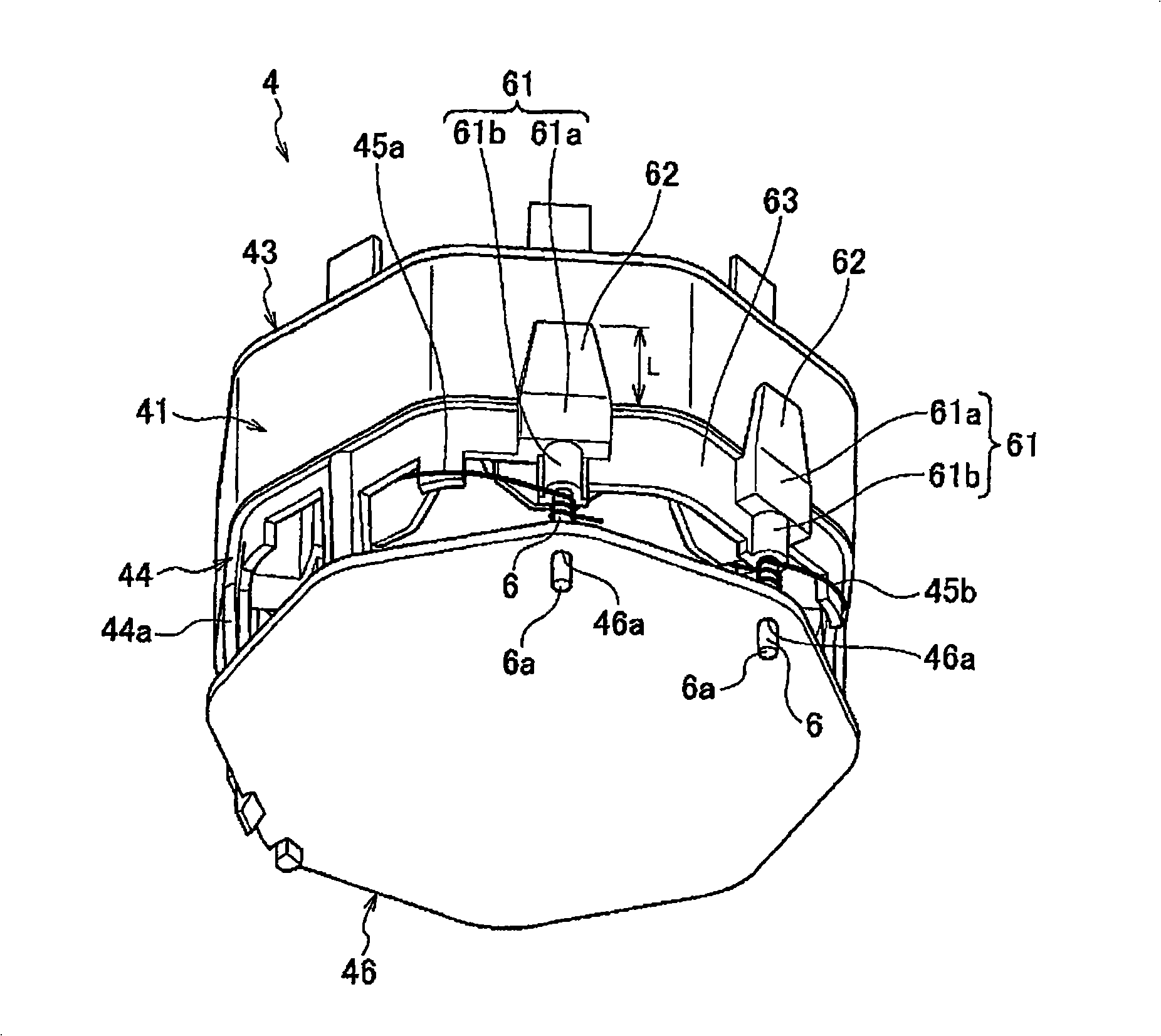

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Figure 1 to Figure 5 A motor-integrated pump according to an embodiment of the present invention is shown. in, figure 1 is a cross-sectional view of the motor-integrated pump according to the present embodiment, figure 2 is an exploded perspective view of the stator, image 3 It is a perspective view showing an assembled state of a stator, Figure 4 is along figure 1 A cross-sectional view of line IV-IV in, Figure 5 yes Figure 4 An enlarged sectional view of the V portion in .

[0024] like figure 1 As shown, the motor-integrated pump 1 includes a pump 2 and a motor 3 . An impeller 23 constituting a centrifugal pump is rotatably accommodated in a pump chamber 22 of the pump casing 21 . In addition, a suction port 22 a is formed in the central portion of the pump chamber 22 , and a discharge port 22 b is formed in the tangential direction of the peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com