Receptacle comprising a lid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

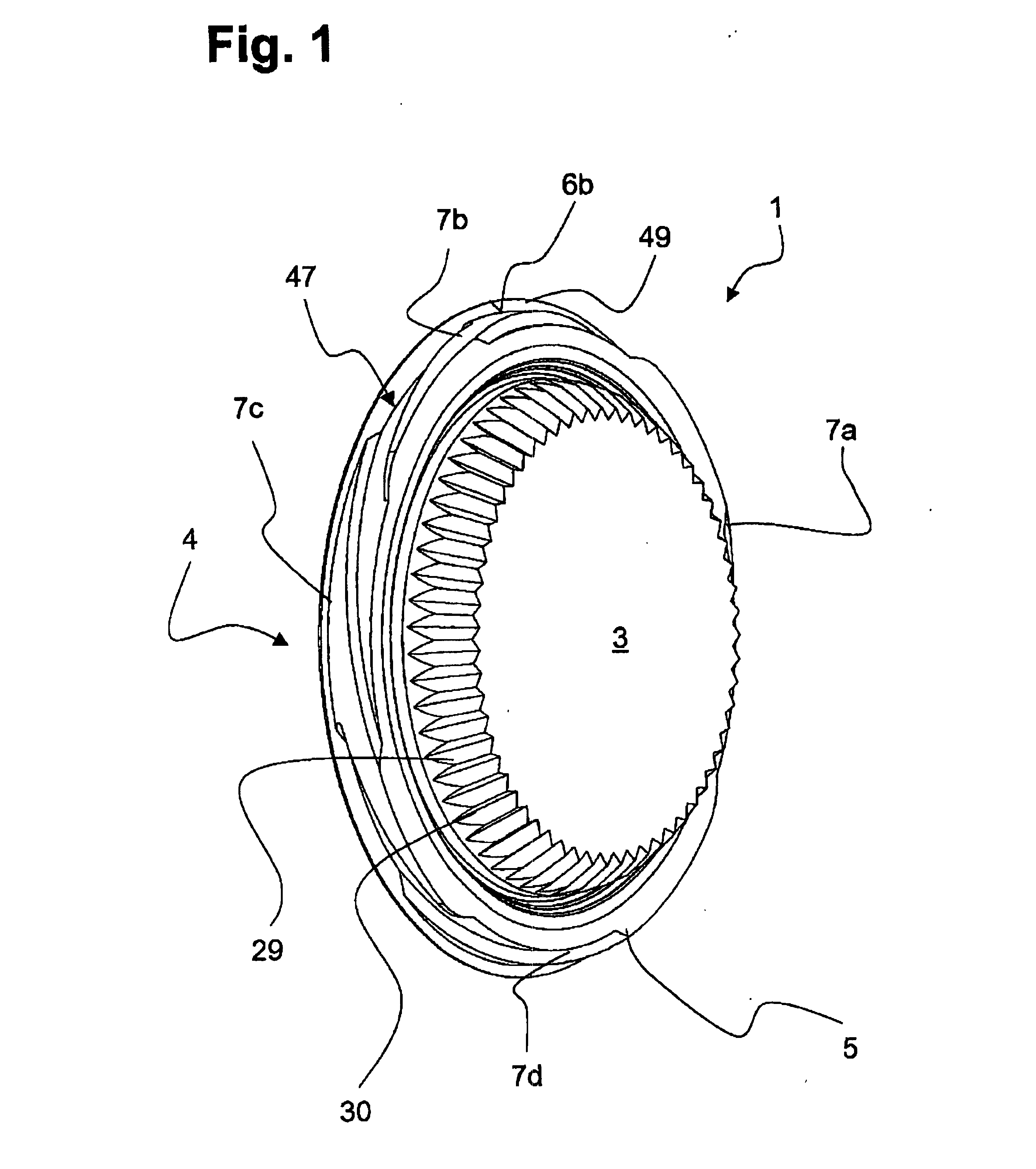

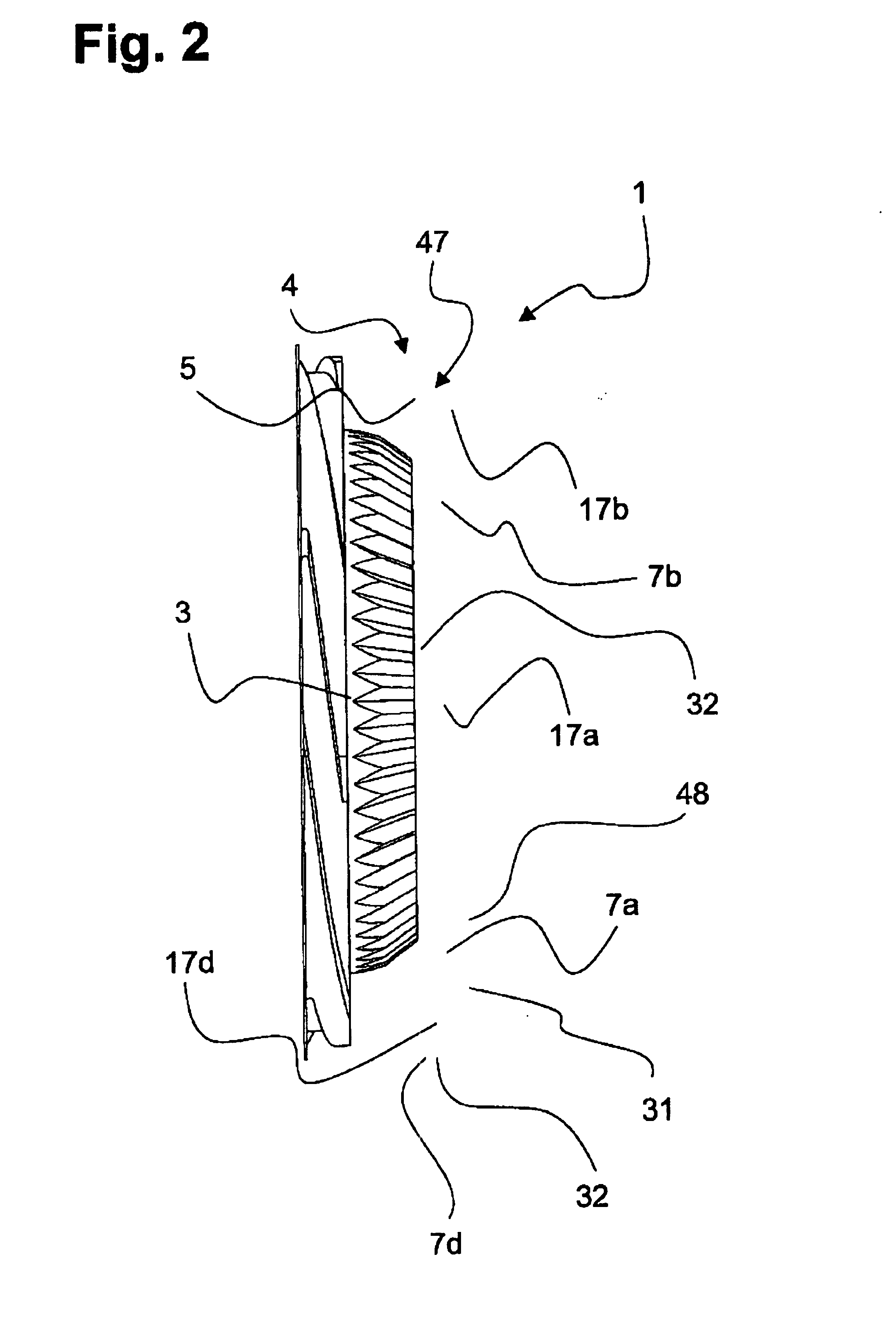

[0065]FIG. 1 shows a first shell in the form of a top shell 1. The top shell 1 has a convex pot-type central part 3 arced outward, with its circumferential wall 29 transferring into a holding edge 4. A step like reducing collar 5 is located between the pot-type central part 3 and the holding edge 4. The circumferential wall 29 is provided with a ruffled structure 30 also protruding on the interior 29a (see FIG. 4).

[0066] The holding edge 4 is provided with mounting means 47 in the form of a total of four threads 7a, 7b, 7c, 7d, their contours being embodied both on the inside 6a (see FIG. 3) as well as on the outside 6b of the holding edge 4. Using the threads 7a, 7b, 7c, 7d a second shell (see FIG. 7) embodied as a bottom shell 2, for example, can be fastened to the top shell 1.

[0067] The holding edge 4 is also surrounded at the outside by an encircling punched edge 49. Said edge has a larger diameter than the top shell 1, because it has been separated from a sheeting 23 during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com