Safety railing for building construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

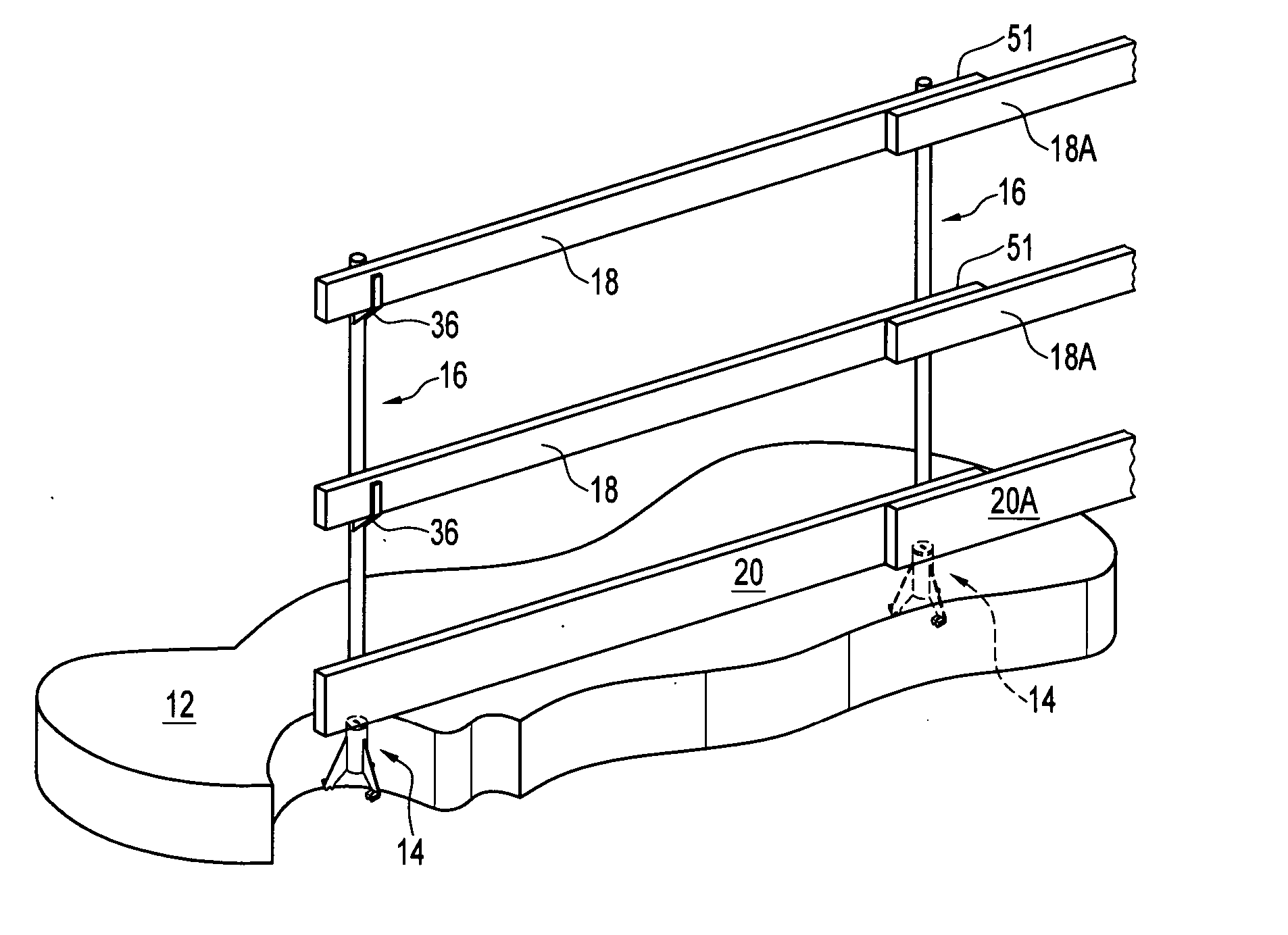

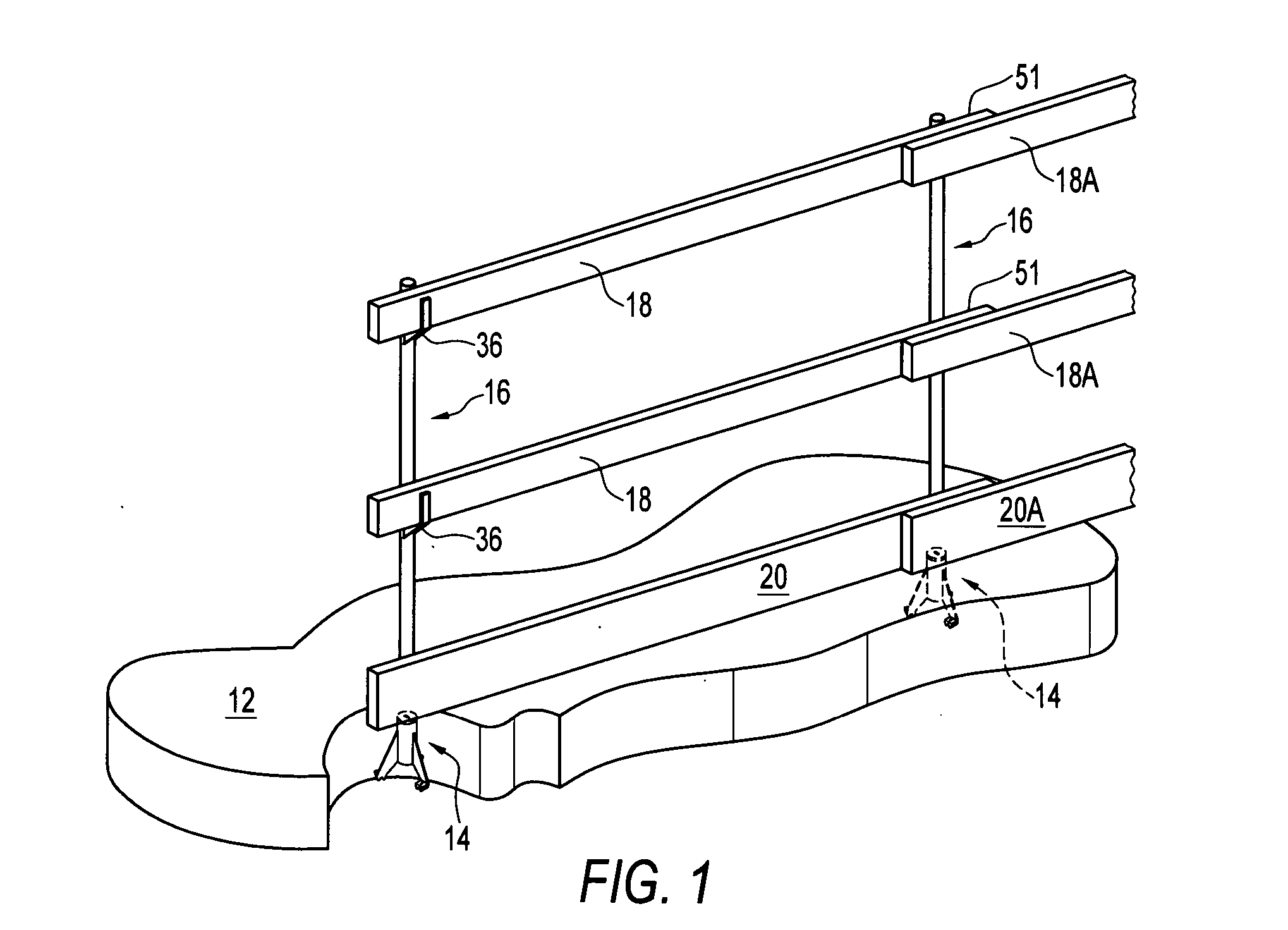

[0031] In FIG. 1 of the accompanying drawings, there is shown a safety railing, indicated generally by reference 10, which is installed on a concrete floor 12. The safety railing 10 has post sockets, of which only one is shown in FIG. 1 and is indicated generally by reference numeral 14, posts indicated generally by reference numerals 16, and horizontal rails 18 supported on the posts 16. A lowermost rail, commonly referred to in the construction industry as a “kick rail”, is indicated by reference numeral 20 and supported on the concrete floor 12 by the posts 16.

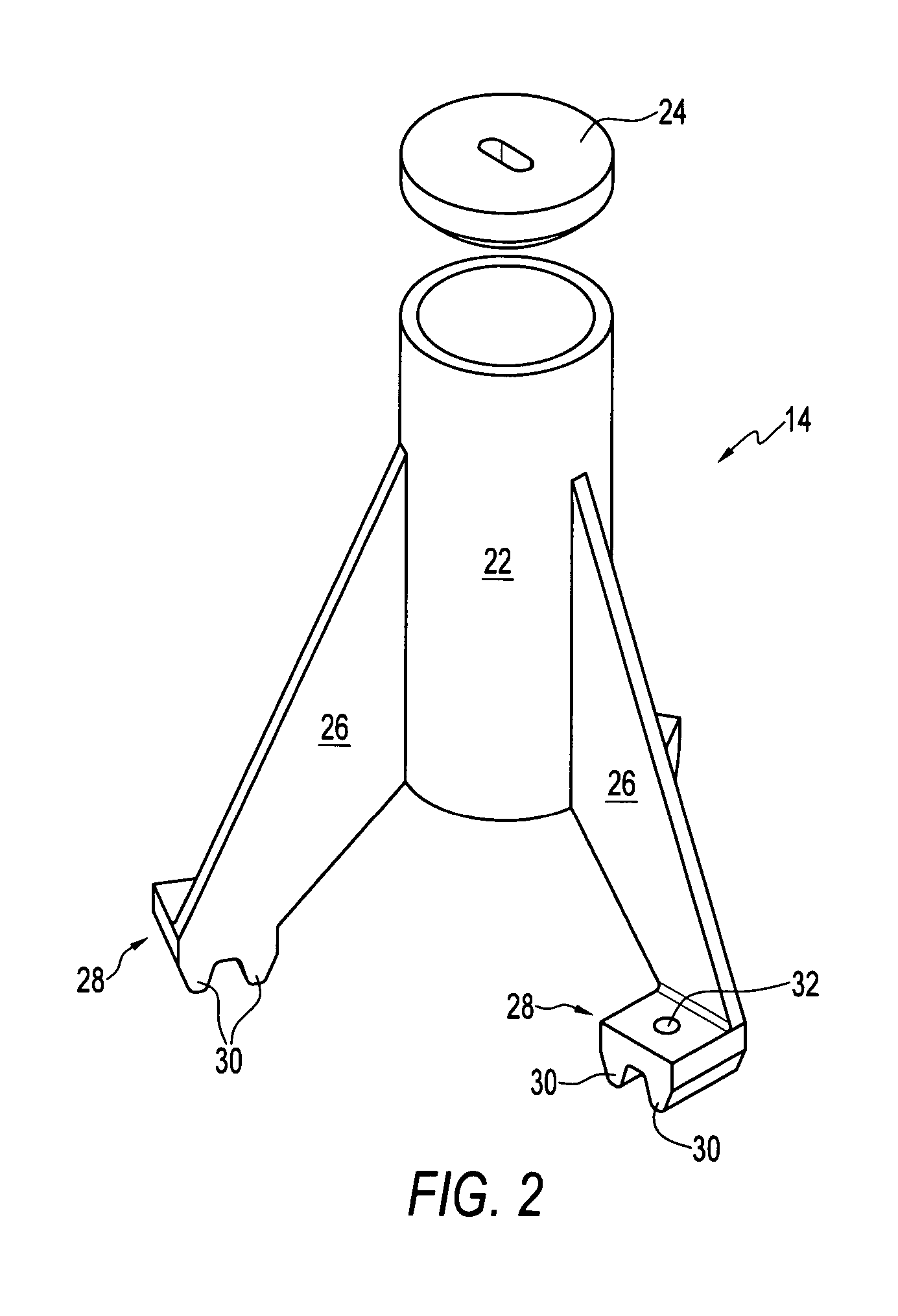

[0032] One of the post supports 14 is illustrated in greater detail in FIGS. 2 through 4, and comprises an open-topped cylindrical post socket 22, with a circular lid 24 for closing the top of the cylindrical post socket 22.

[0033] The cylindrical post socket 22 is provided on a socket supports formed by three legs or support members in the form of flanges 26, which are equi-angularly spaced apart around the cylindrical po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com