Power impact tool adapter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

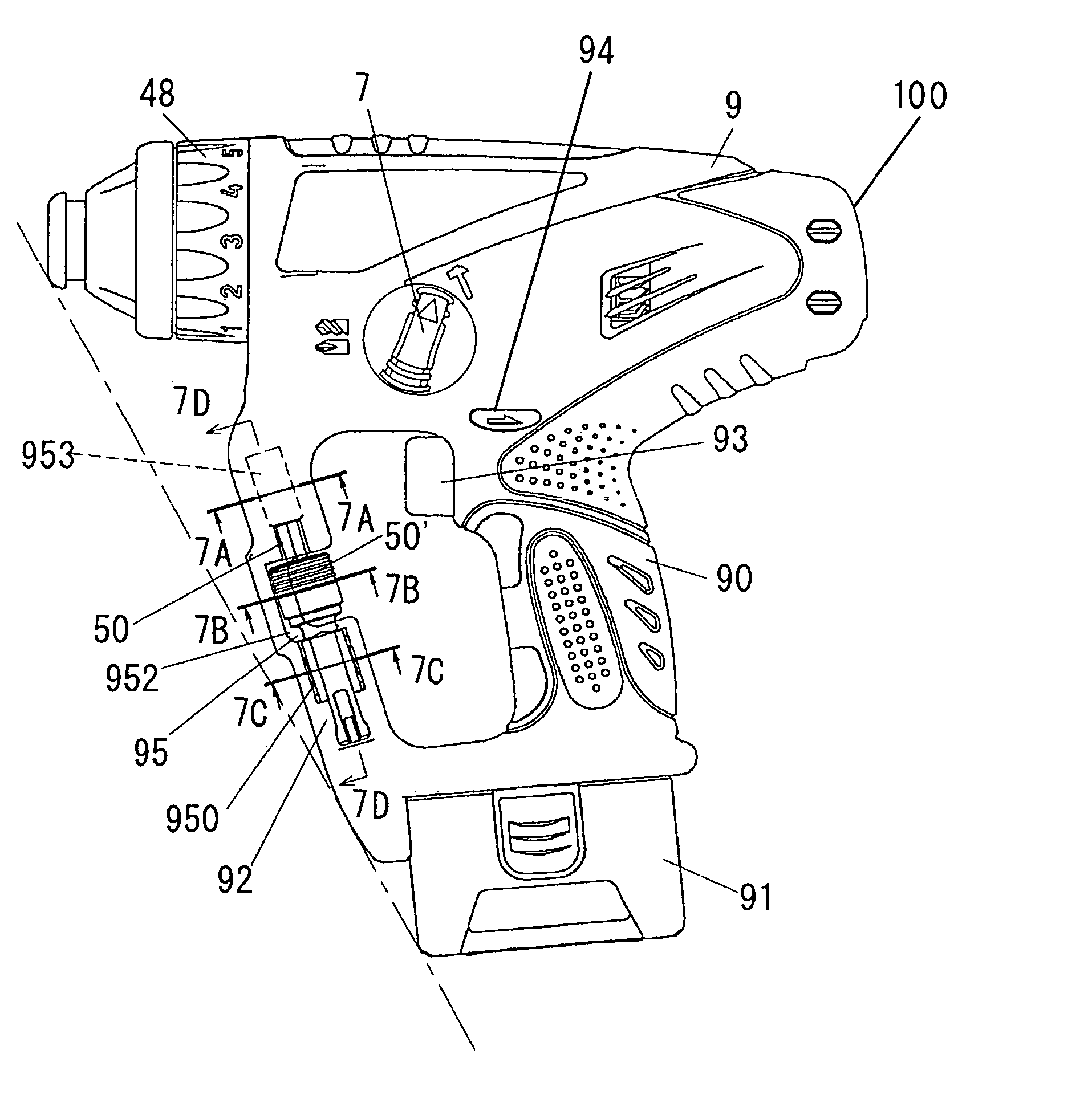

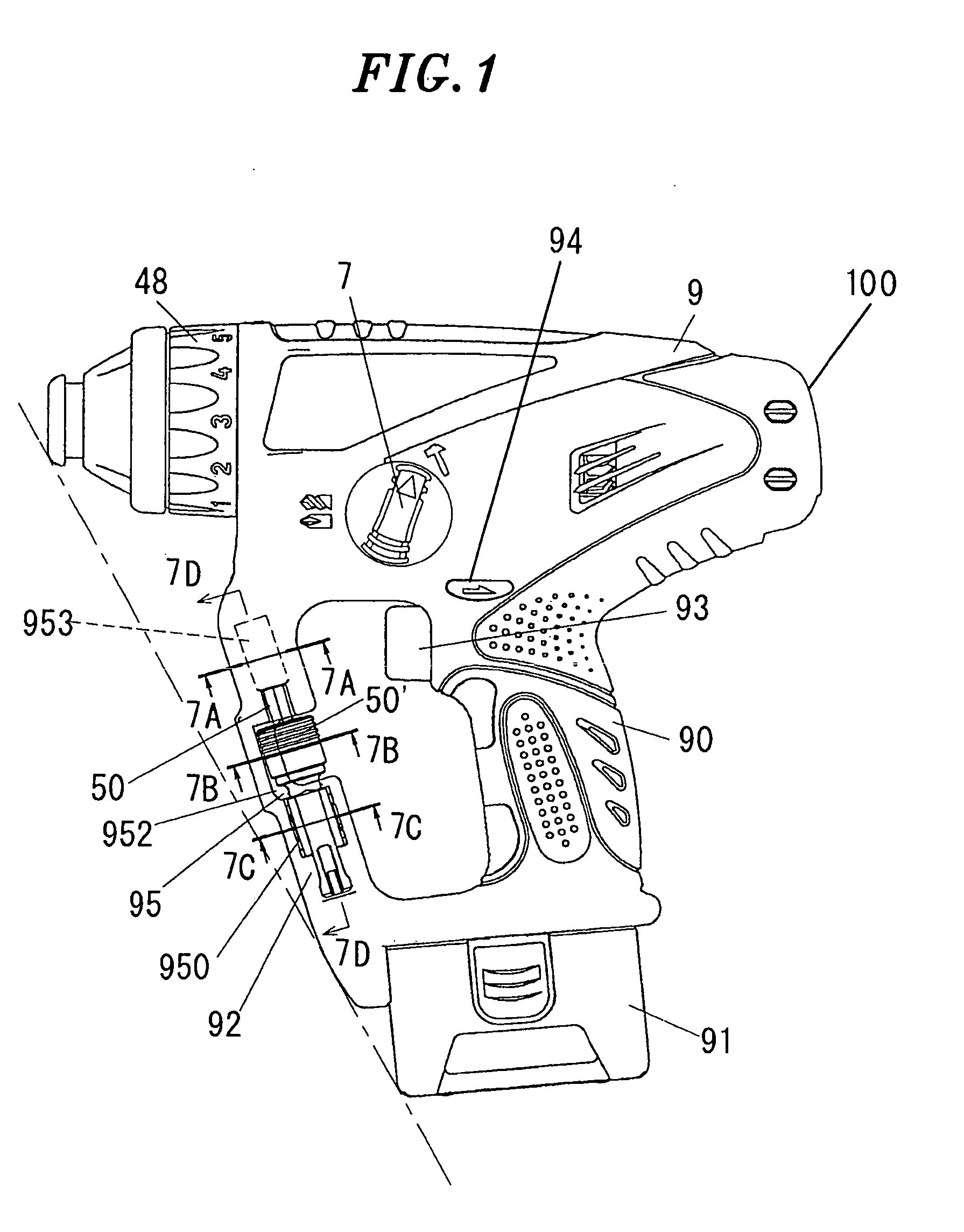

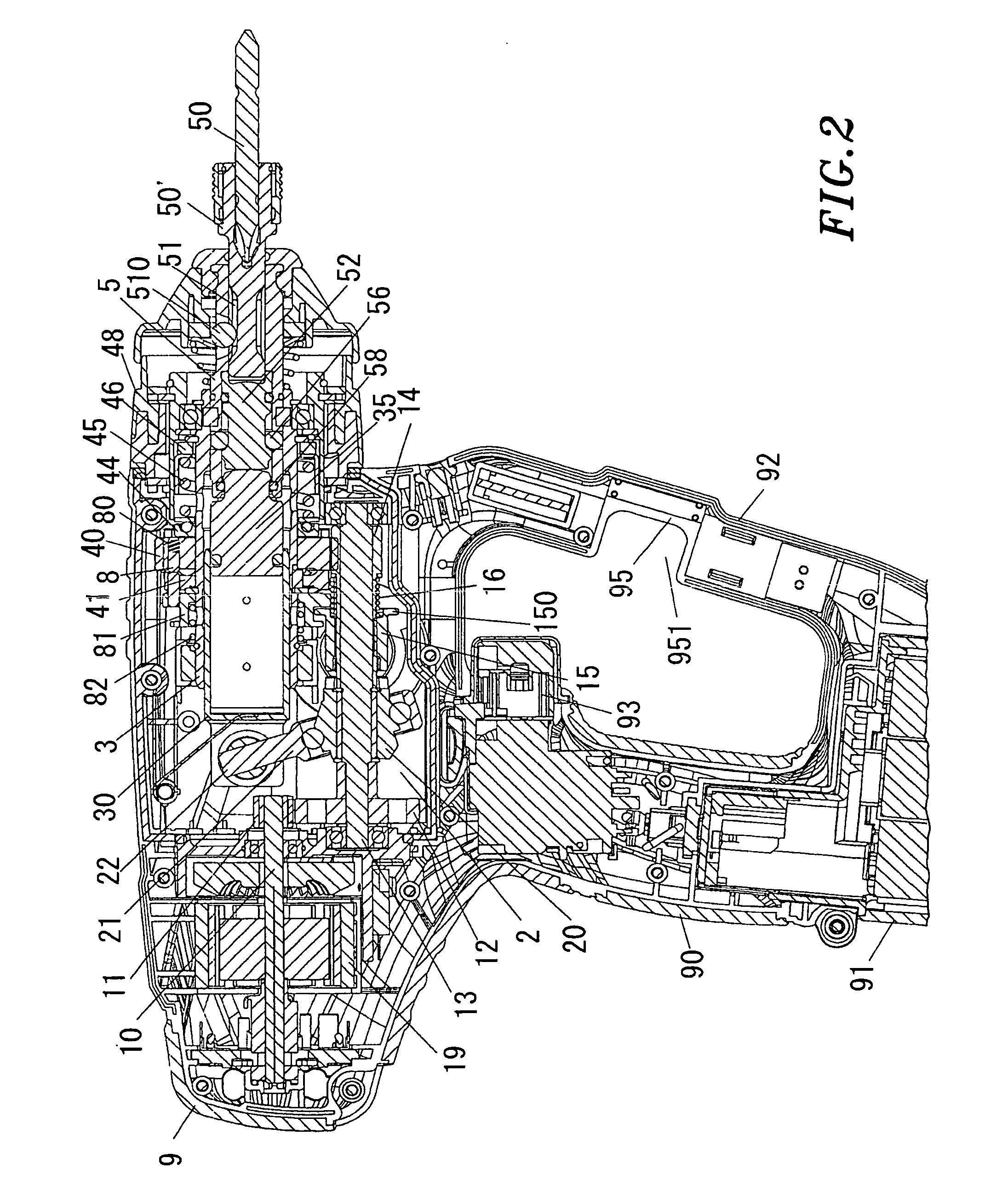

[0021] Hereinafter, there will be described embodiments of the present invention with reference to the accompanying drawings.

[0022] In an embodiment of the present invention as shown in FIGS. 1 to 9, it is discussed that a power tool shown thereof is a hammer drill capable of transferring a rotational force and applying a striking force in an axial direction and includes a striking-motion-deactivated mode that is capable of transferring only the rotational force to an output bit. Reference numeral 9 in the drawings designates a housing with which a grip portion 90 is formed integrally so as to extend downwardly therefrom. A battery pack 91 is detachably attached to the bottom of the grip portion 90. A housing-reinforcing connecting portion 92 is integrally formed between the bottom frontal end of the grip portion 90 and the front end of the housing 9. Reference numeral 93 in the drawings designates a trigger switch disposed at a base portion of the grip portion 90. Disposed within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com