Battery venting system

a battery and venting technology, applied in the direction of secondary cell servicing/maintenance, cell components, grouping of flat cells, etc., can solve the problems of reducing the cell capacity, reducing the service life of the cell, so as to achieve the effect of further enhancing the venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

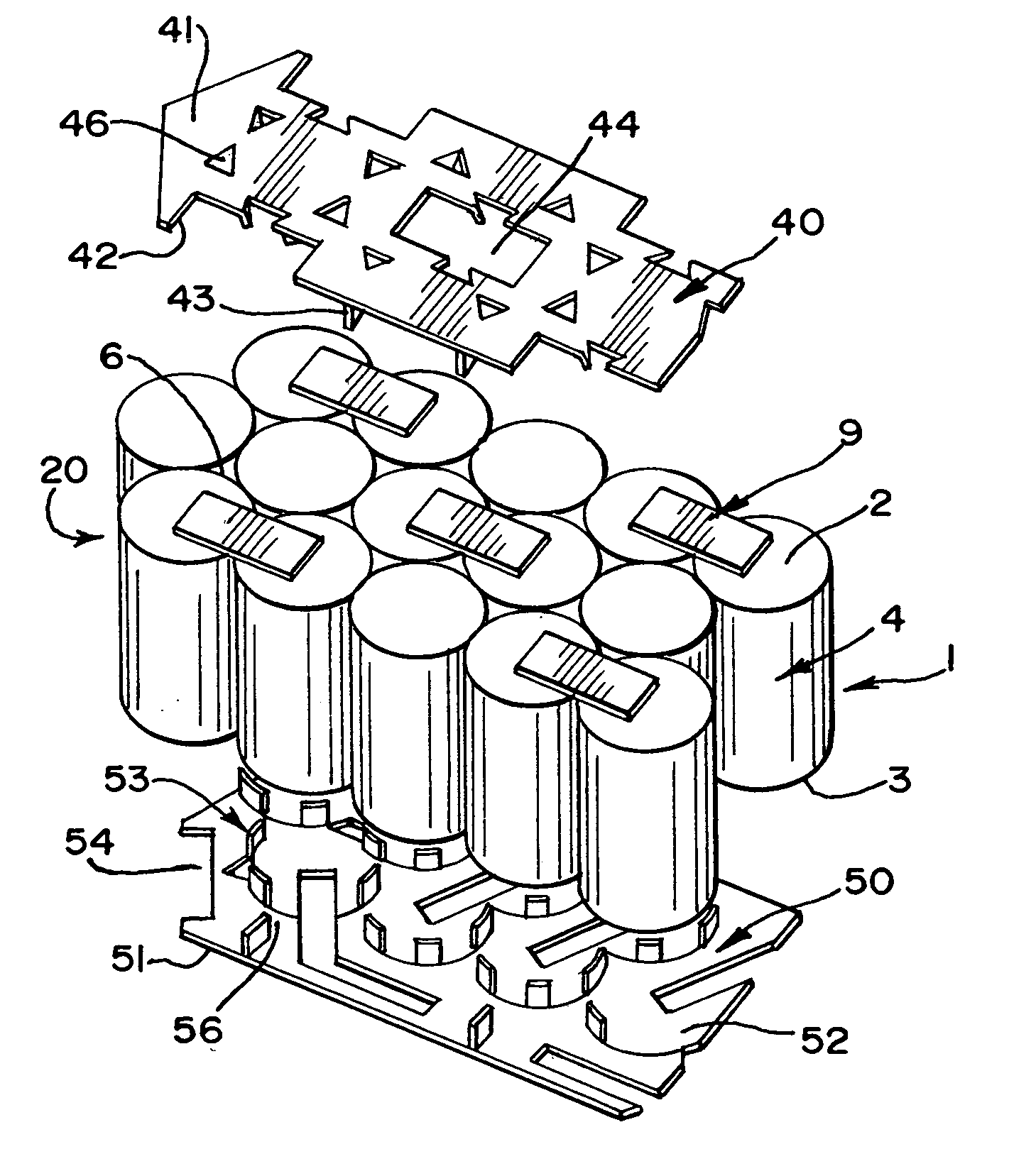

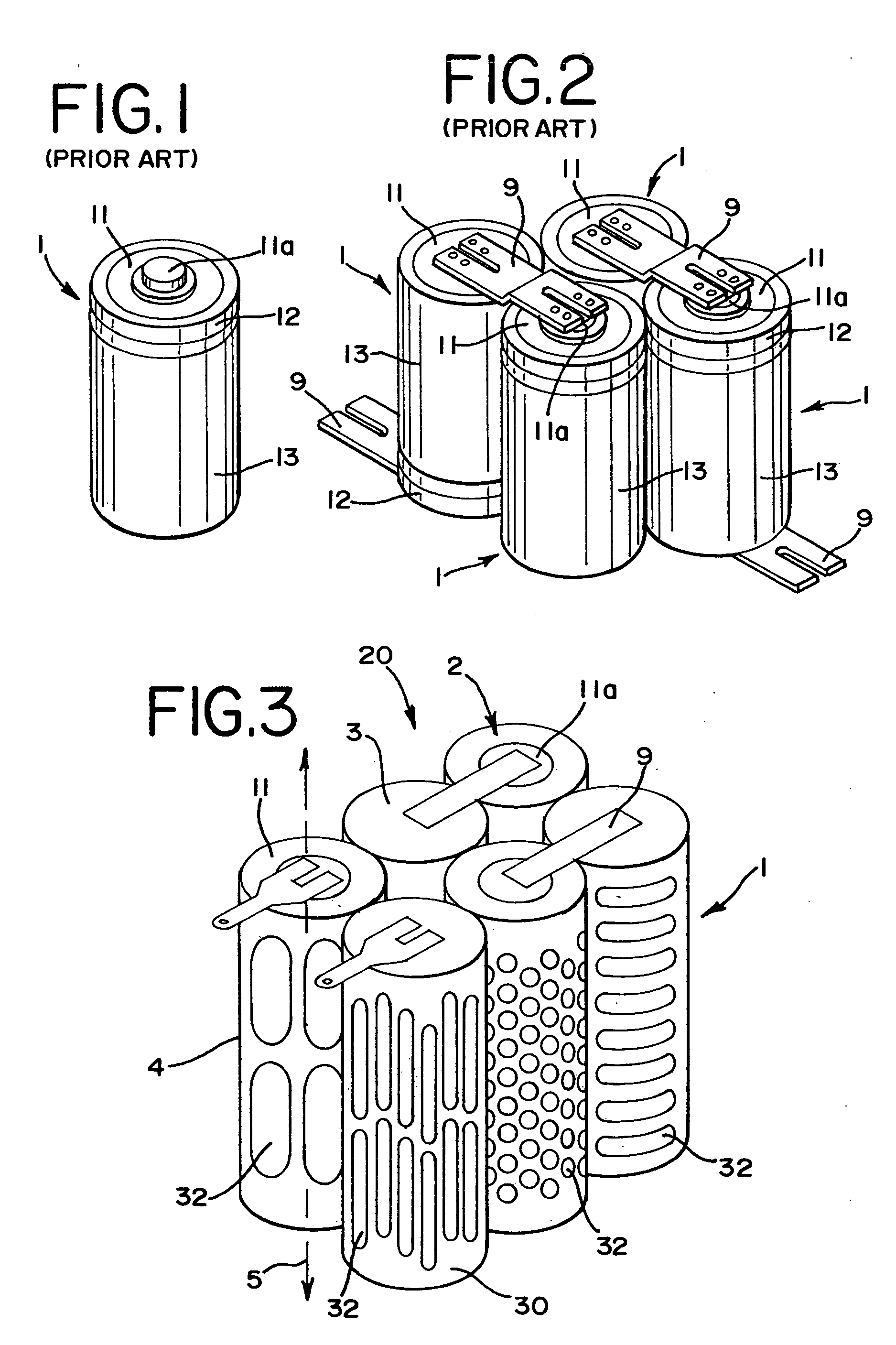

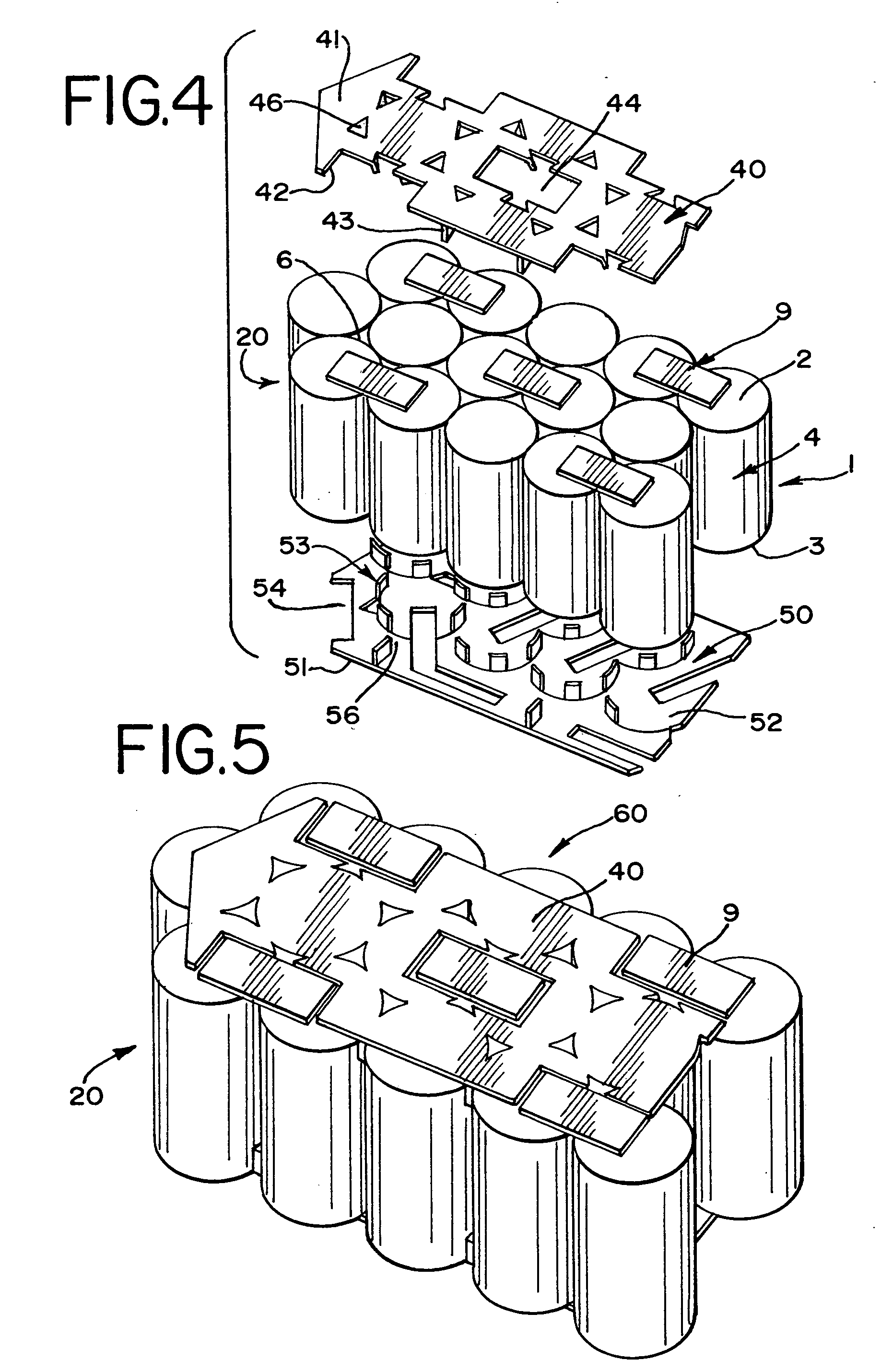

[0028] Referring now to the drawings and initially to FIG. 1, a prior art battery cell is shown. The prior art battery cell 1 has a cylindrical case that contains the cell materials in a closed fashion by a cover 11. A conductive projection 11a is formed in the cover 11, and a safety valve for releasing gasses is disposed in the projection 11a. Generally, the cover 11 having the projection 11a is the positive electrode and the case 12 is the negative electrode. Generally, an outer sleeve 13 is formed from an electrically insulating material so that when the battery cells are intentionally or unintentionally touching each other at the peripheral side face, the battery cells will not discharge.

[0029] When the prior art cylindrical cell 1 is to be used as a power source for an apparatus, generally, a plurality of cells are connected to each other to form a cell pack, as shown in FIG. 2. Two adjacent cells 1 are bridged by an electrically conductive plate 9, such as a nickel plate. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com