Light weight paper frame and method for fabricating same

a paper frame and light weight technology, applied in the field of photographs, can solve the problems of complex operation, time-consuming and frustrating for users, and relatively bulky and costly conventional frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

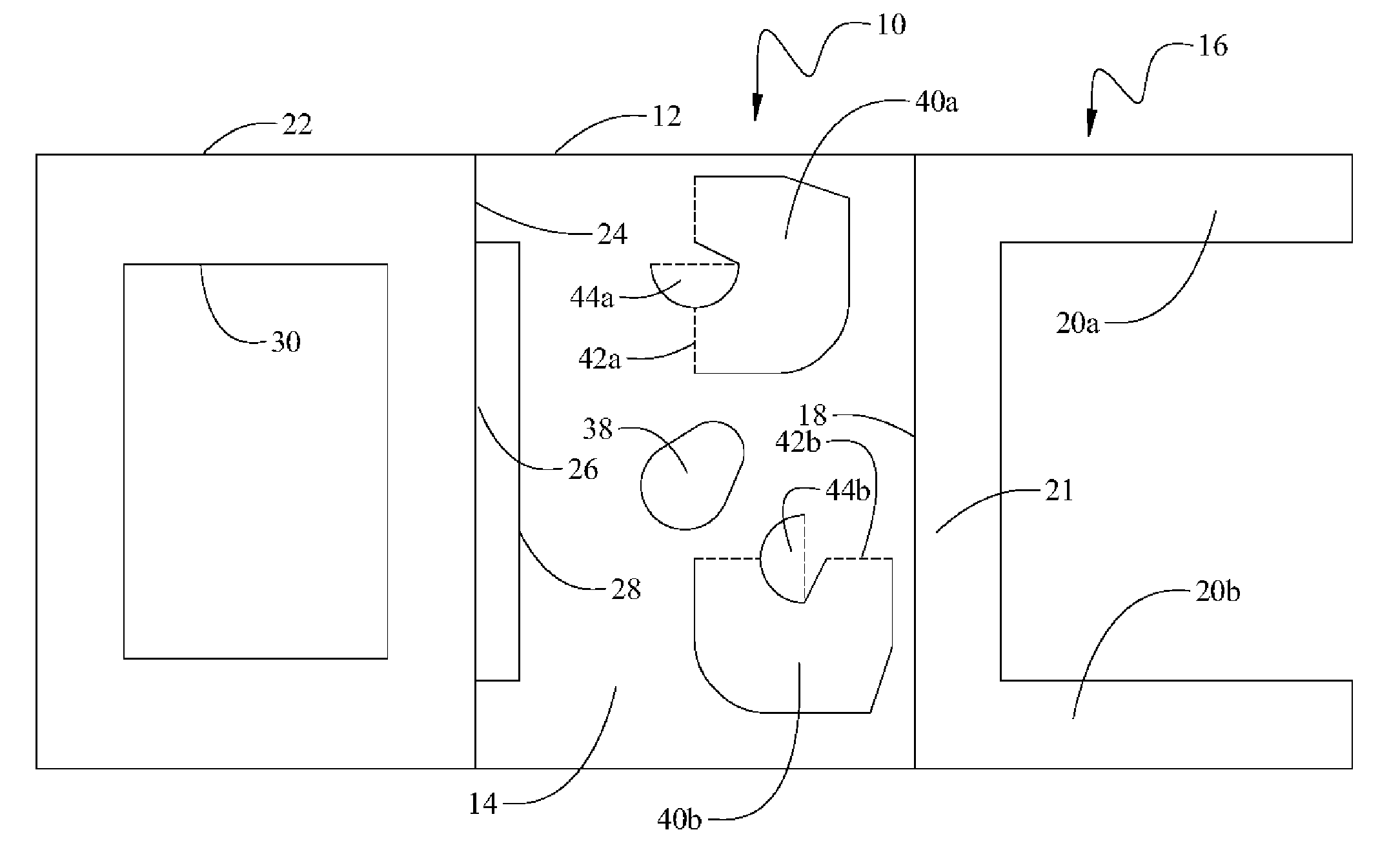

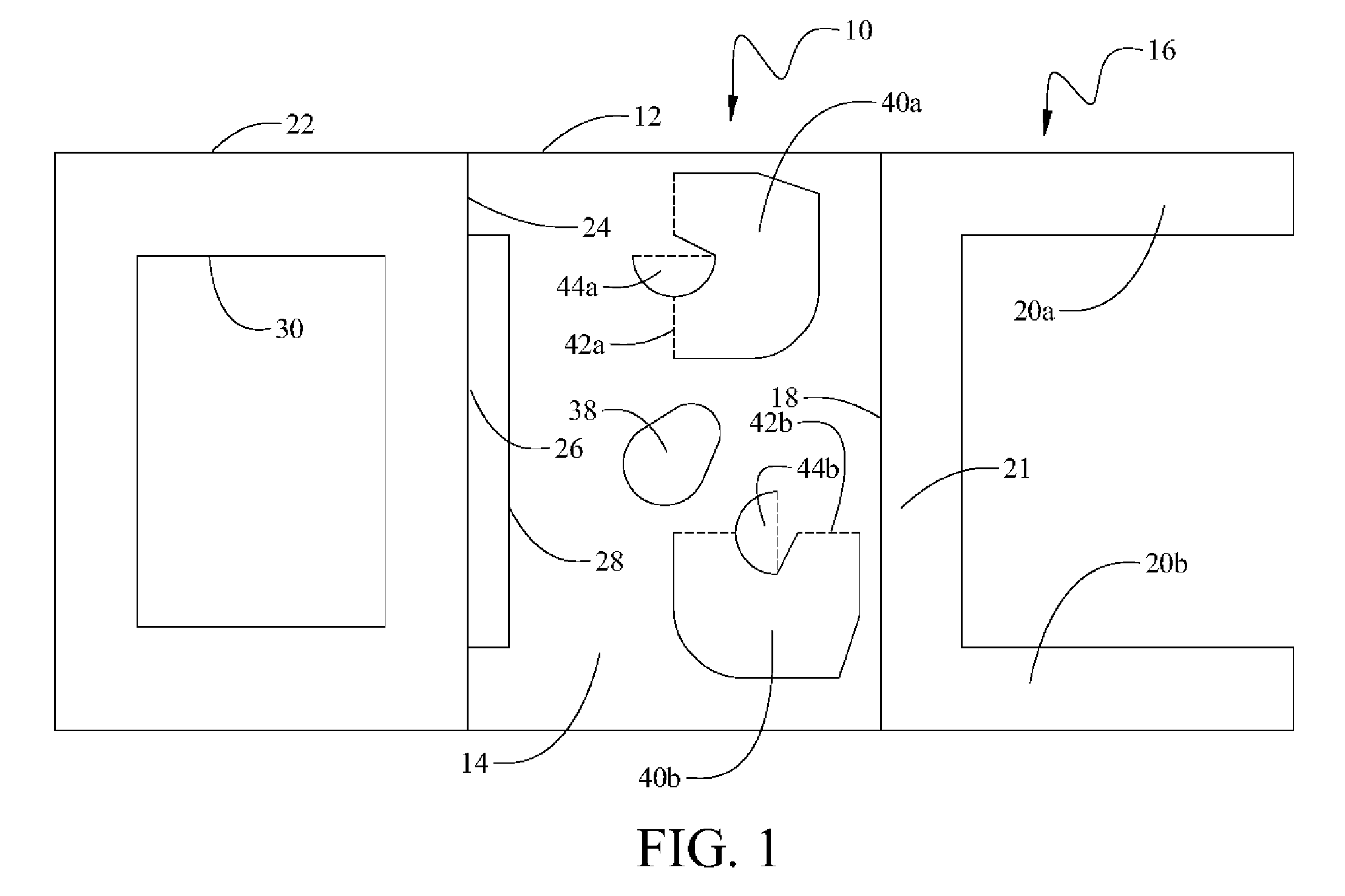

[0022] For the first embodiment, a face structural portion 22 is attached to the first portion at a second fold line 24 opposite the second portion. A slot 26 having a length substantially equal to the spacing of the lateral elements in the second portion is present in the second fold line. A rectangular relief 28 extends the slot into the backing of the first portion to assist in insertion of a photograph. The relief not only provides additional ability to manipulate one edge of the photograph but increases the flexibility of the backing out of plane to reduce friction on the photograph during insertion by allowing flexing of the backing.

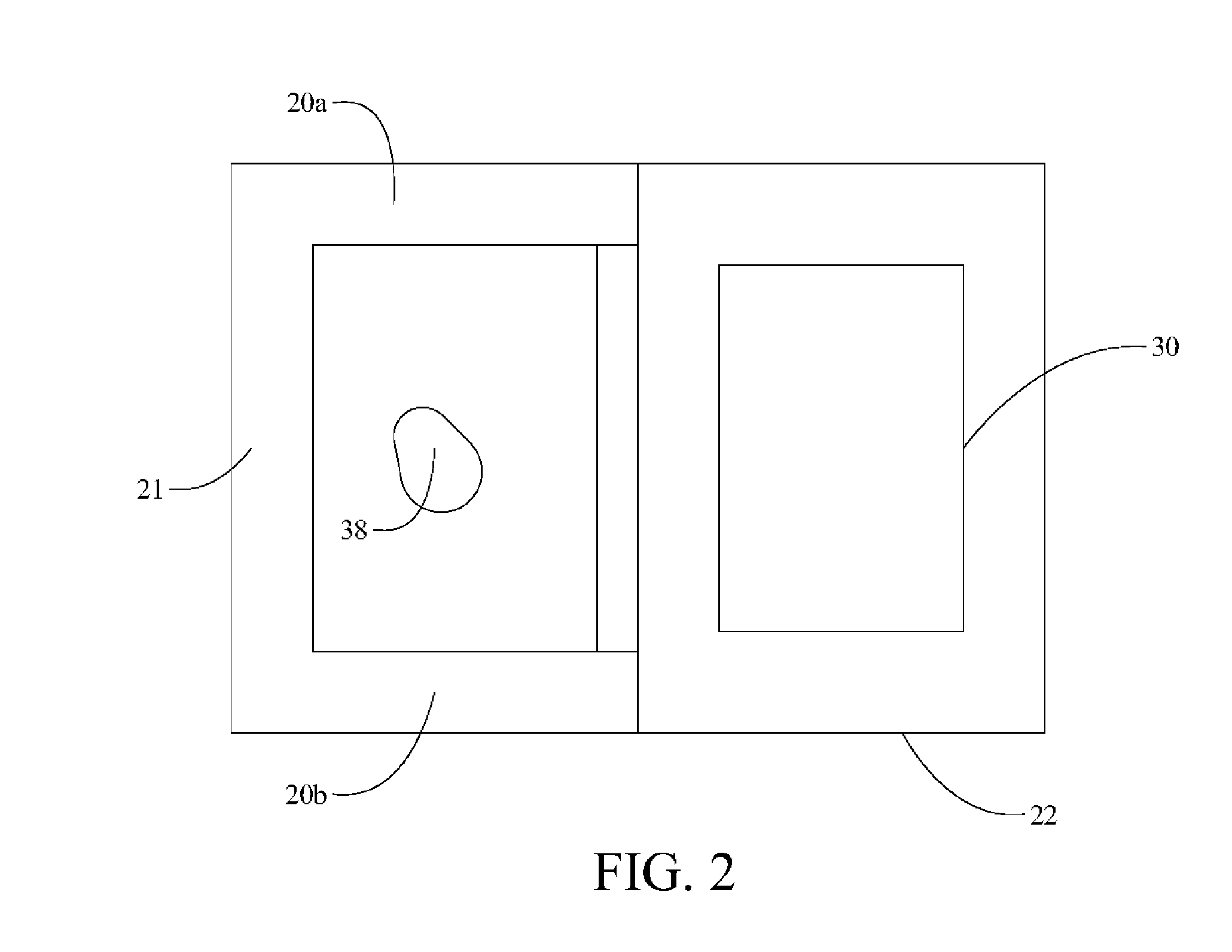

[0023] The face structural portion is folded over the lateral elements resting on the backing as shown in FIG. 3. A rectangular opening 30 in the face structural portion allows the photograph to be viewed and acts in certain embodiments as a matte for outlining the photograph. The transverse dimension 32 of the opening is less than the spacing of t...

second embodiment

[0028] a frame according to the present invention is shown in FIGS. 6-8. This simplified embodiment reduces the raw material required. As in the prior embodiment, the first portion of the structural element incorporates a backing 14. As shown in FIG. 6, the spaced lateral elements 50a and 50b of the second portion are positioned transversely on the first portion with fold lines 52a and 52b respectively. When folded as shown in FIG. 7, the lateral elements then provide a volume to receive a photograph and to constrain two opposing sides of the photograph for positioning. A web 54 is provided attached to the first portion along a fold line 56 and, when folded, assists in constraining an inserted photograph as previously described. A face structural portion 58 is mounted to the spaced lateral elements with an aperture 60 for viewing the photograph. A rectangular relief 62 in the backing enhances flexibility of the backing and cooperates with the web for positioning of the photograph as...

third embodiment

[0037] The third embodiment is also substantially similar in assembly however the rectangular paper sheet is scored or marked with two fold lines laterally spaced on the first backing portion; one at the top for the first lateral element, a second at the bottom for the second lateral element. The tabs extending from the first and second lateral elements providing a partial web for constraining the photograph. A rectangular relief is then cut into the first backing portion on the edge opposite the tabs. In alternative embodiments, the relief extends for the full length between the first and second fold lines or for a lateral extent of the side between the first and second lateral elements when folded. The restraining member is then scored into the first backing portion. The face structural element has the aperture cutout made and is then adhesively bonded to the first and second lateral elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com