Electronic module and method for the production thereof

A technology of electronic components and electronic components, which is applied in the direction of printed circuit manufacturing, electrical components, printed circuits connected with non-printed electrical components, etc., and can solve problems such as high cost and single board thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

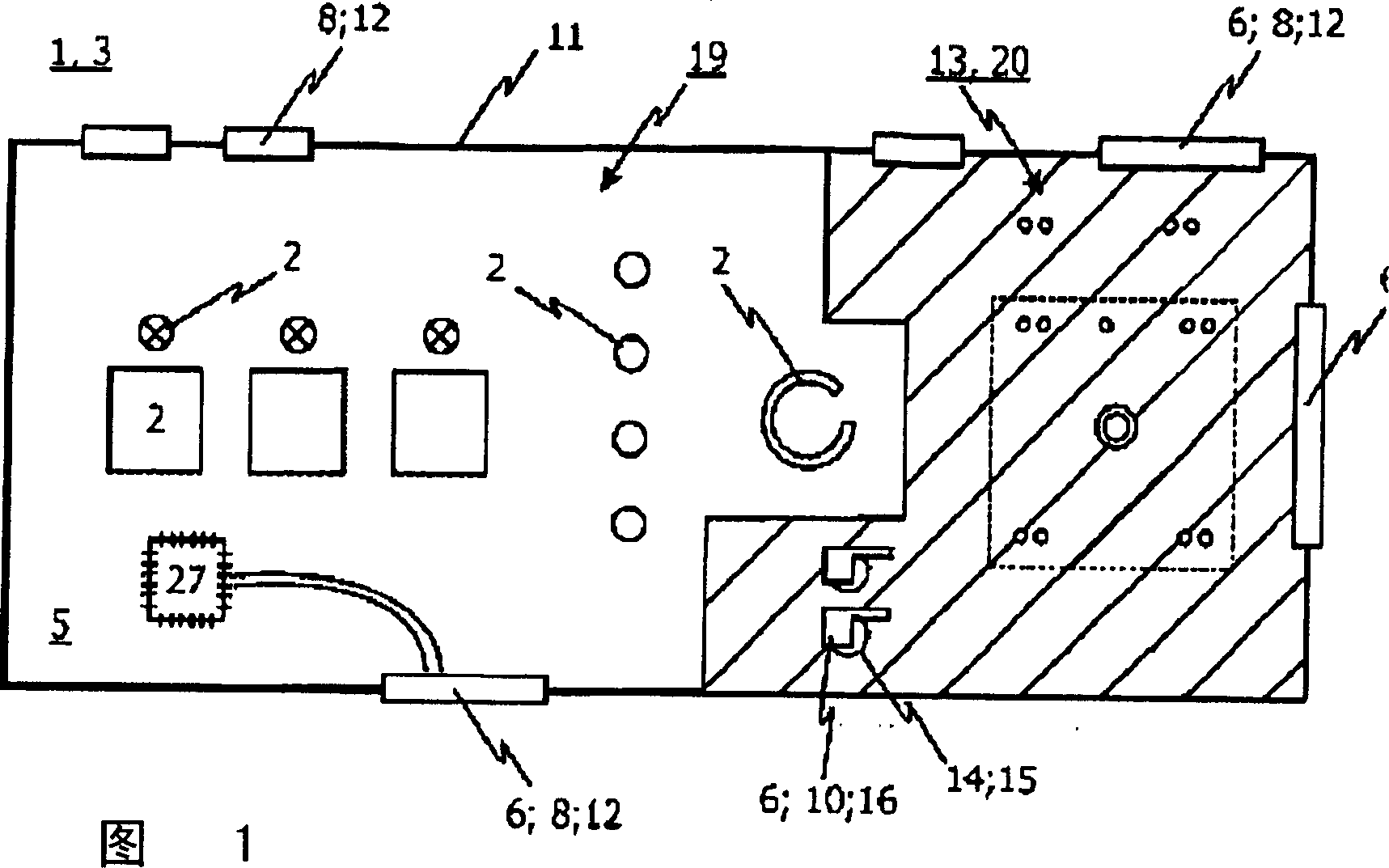

[0032] FIG. 1 shows the concealed side 5 of a preferred embodiment of an electronic component 1 . The embodiment shown here relates to a first variant of the assembly 1 in which the wave soldering area 20 of the SMD component 2 on one SMD area 19 and the THD component 4' arranged on the appliance side 7 is located on the concealed side 5.

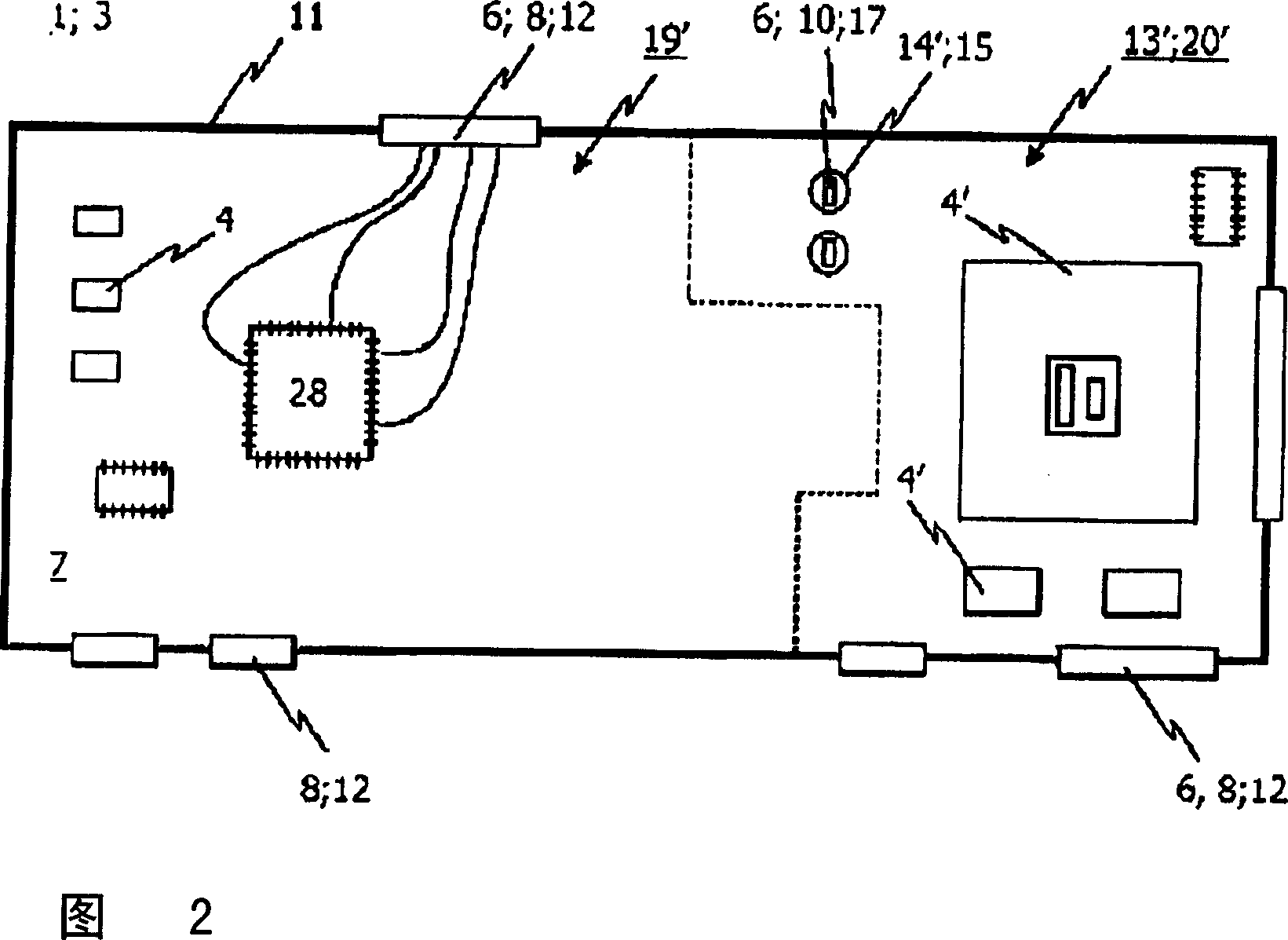

[0033] FIG. 2 shows the appliance side 7 of the first preferred embodiment of the electronic assembly 1 corresponding to the concealed side 5 shown in FIG. 1 . On the electrical side 7, both SMD components 4 and THD components 4' are provided, wherein the THD component 4' is arranged on the THD area 20' of the electrical side 7, which is exactly the same as the wave soldering area 20 of the concealed side 5 relatively. The SMD components 4 can be arranged on the appliance side 7 both in the THD region 20' and in the SMD region 19'. The SMD area 19' on the electrical side 7 is exactly opposite to the SMD area 19 on the concealed side 5.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com