Acoustic galvanic isolator

a galvanic isolator and acoustic technology, applied in the direction of impedence networks, electrical equipment, etc., can solve the problems of inconvenient fabrication, inconvenient use, and inability to provide an absolute break in the conduction path of capacitors, etc., and achieve the effect of being inexpensive to manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

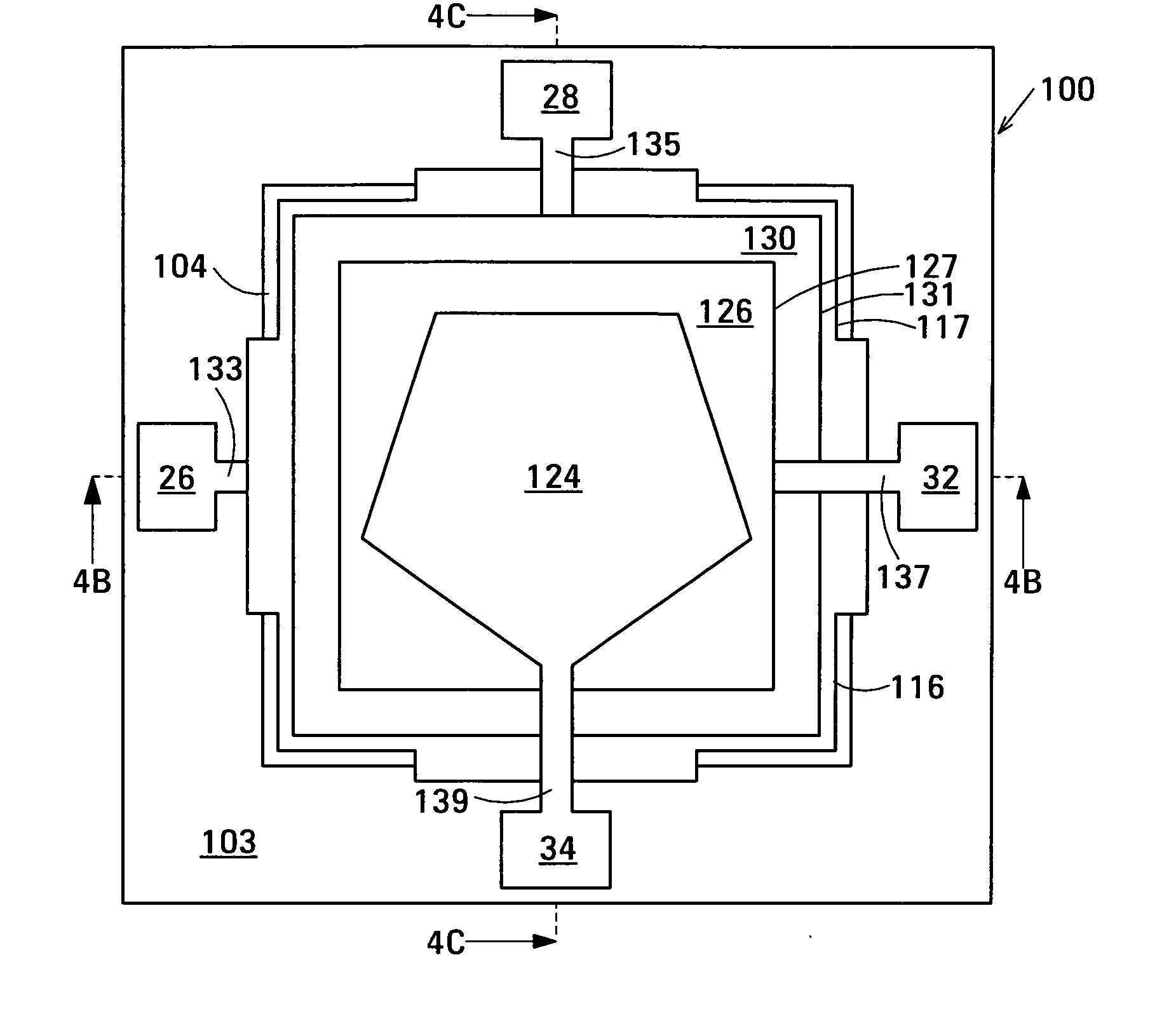

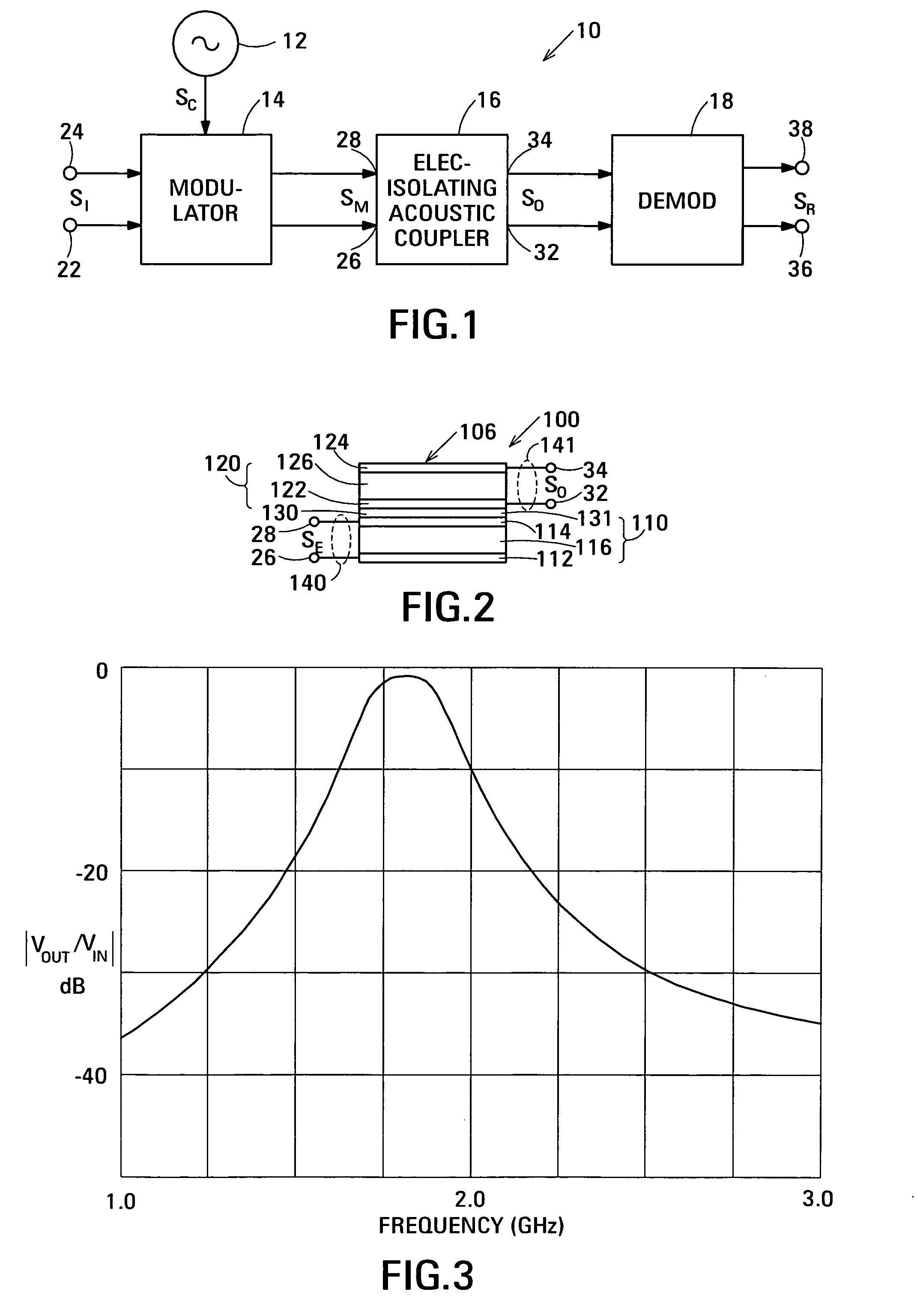

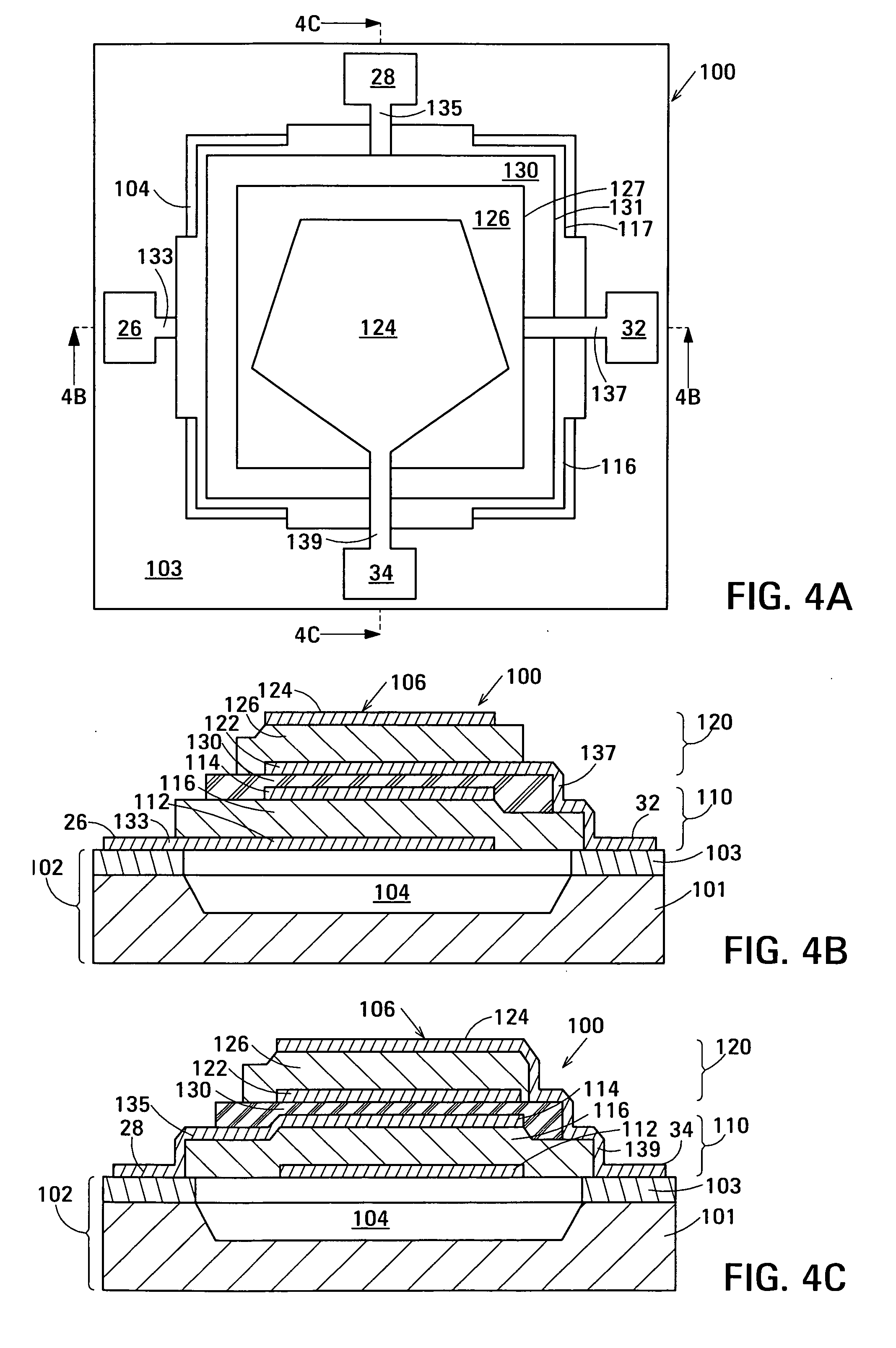

[0056]FIG. 2 is a schematic diagram showing an example of an acoustic coupler 100 in accordance with the invention. Acoustic coupler 100 comprises a single decoupled stacked bulk acoustic resonator (DSBAR) 106, inputs 26, 28, outputs 32, 34, an electrical circuit 140 that connects DSBAR 106 to inputs 26, 28 and an electrical circuit 141 that connects DSBAR 106 to outputs 32, 34. DSBAR 106 incorporates an electrically-insulating acoustic decoupler 130 that provides electrical isolation between inputs 26, 28 and outputs 32, 34.

[0057] When used as electrically-isolating acoustic coupler 16 in acoustic galvanic isolator 10 shown in FIG. 1, acoustic coupler 100 acoustically couples modulated electrical signal SM from inputs 26, 28 to outputs 32, 34 while providing electrical isolation between inputs 26, 28 and outputs 32, 34. Thus, acoustic coupler 100 effectively galvanically isolates output terminals 36, 38 from input terminals 22, 24, and allows the output terminals to differ in volta...

second embodiment

[0081]FIG. 5B is an enlarged view of the portion marked 5A in FIG. 4B showing electrically-insulating acoustic decoupler 130. In the embodiment shown in FIG. 5B, acoustic decoupler 130 is composed of an electrically-insulating acoustic Bragg structure 161. Electrically-insulating acoustic Bragg structure 161 comprises a low acoustic impedance Bragg element 163 located between high acoustic impedance Bragg elements 165 and 167. At least one of the Bragg elements 163, 165 and 167 of Bragg structure 161 comprises a layer of material having a high electrical resistivity, a low dielectric permittivity and a high breakdown field. Low acoustic impedance Bragg element 163 is a quarter-wave layer of a low acoustic impedance material whereas high acoustic impedance Bragg elements 165 and 167 are each a quarter-wave layer of high acoustic impedance material. The acoustic impedances of the materials of the Bragg elements are characterized as “low” and “high” with respect to one another and with...

third embodiment

[0104]FIG. 8 is a schematic diagram showing an example of an acoustic coupler 300 in accordance with the invention. FIG. 9A is a plan view showing a practical example of acoustic coupler 300. FIGS. 9B and 9C are cross-sectional views along section lines 9B-9B and 9C-9C, respectively, shown in FIG. 9A. The same reference numerals are used to denote the elements of acoustic coupler 300 in FIG. 8 and in FIGS. 9A-9C.

[0105] Acoustic coupler 300 comprises inputs 26, 28, outputs 32, 34, and an insulated stacked bulk acoustic resonator (IDSBAR) 306 in accordance with a second IDSBAR embodiment. In its simplest form, an IDSBAR in accordance with the second IDSBAR embodiment has a first half-wave acoustically-resonant electrical insulator, an acoustic decoupler and a second half-wave acoustically-resonant electrical insulator located in order between its constituent FBARs. IDSBAR 306 in accordance with the second IDSBAR embodiment gives acoustic coupler 300 a substantially greater breakdown v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com