Modular system for assembling electromechanically adjustable supporting devices for upholstery of furniture for sitting or reclining

a technology of supporting device and supporting device, which is applied in the direction of rigid tables, tables, sofas, etc., can solve the problems of high production cost and system cost, and achieve the effect of simple and cost-effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

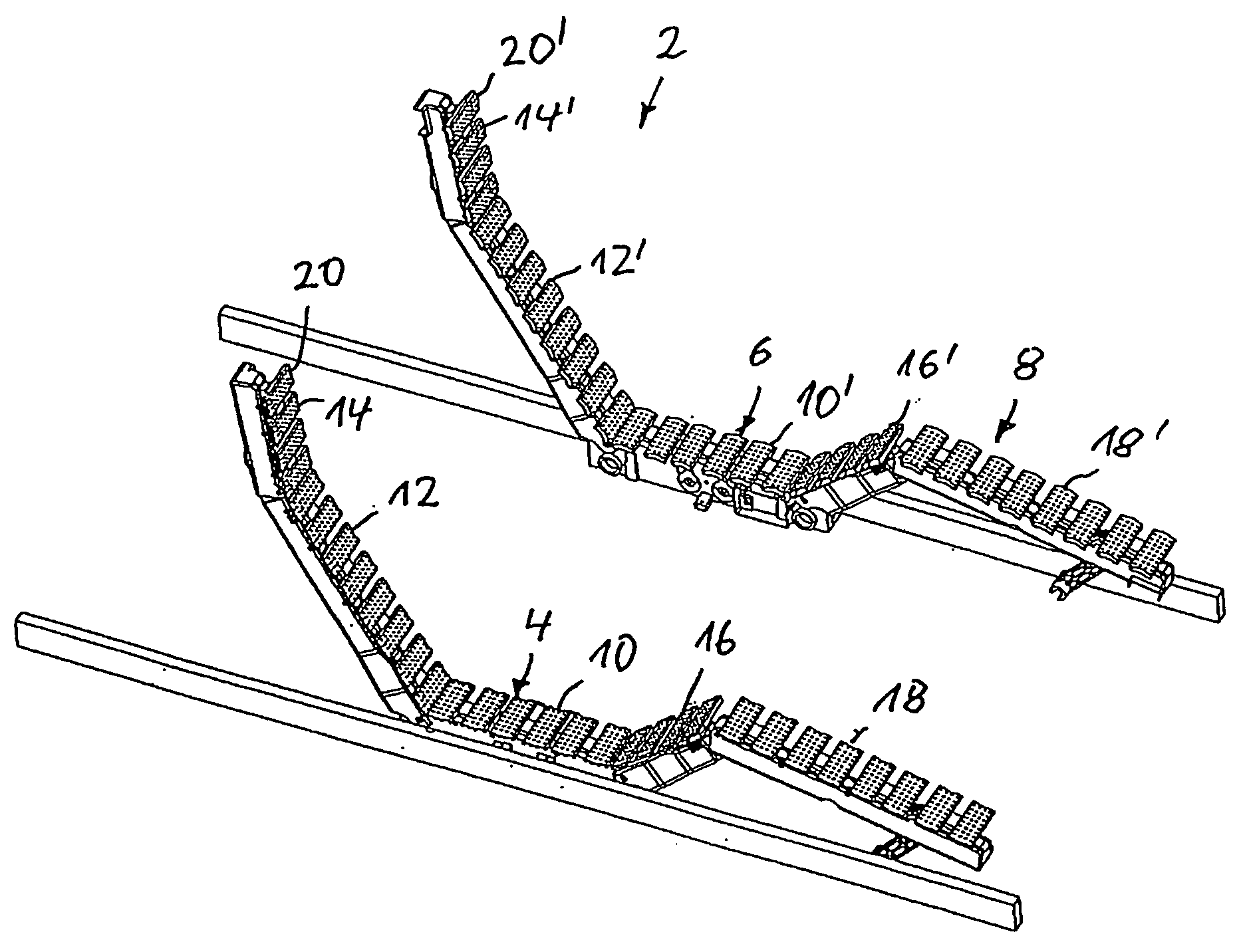

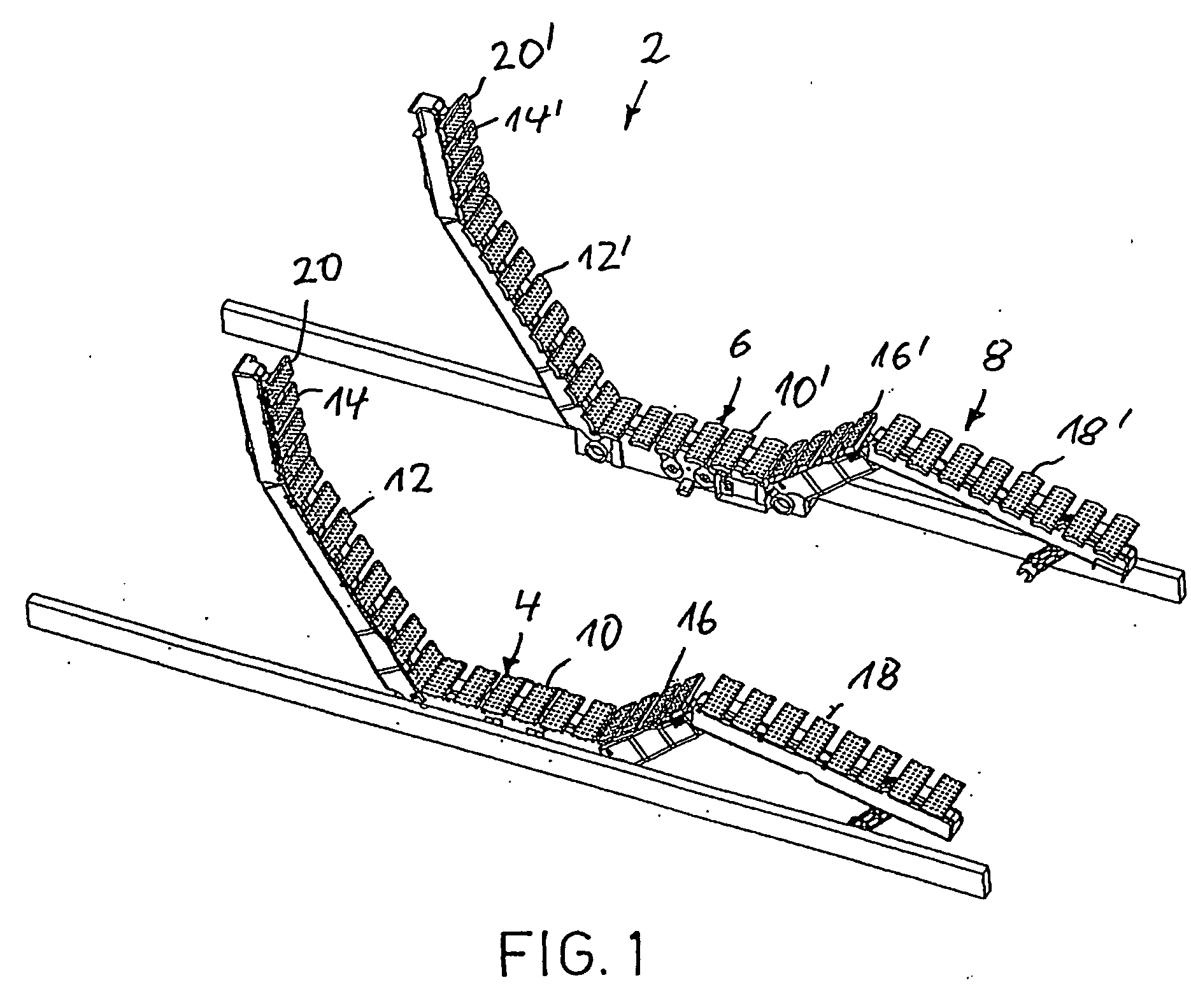

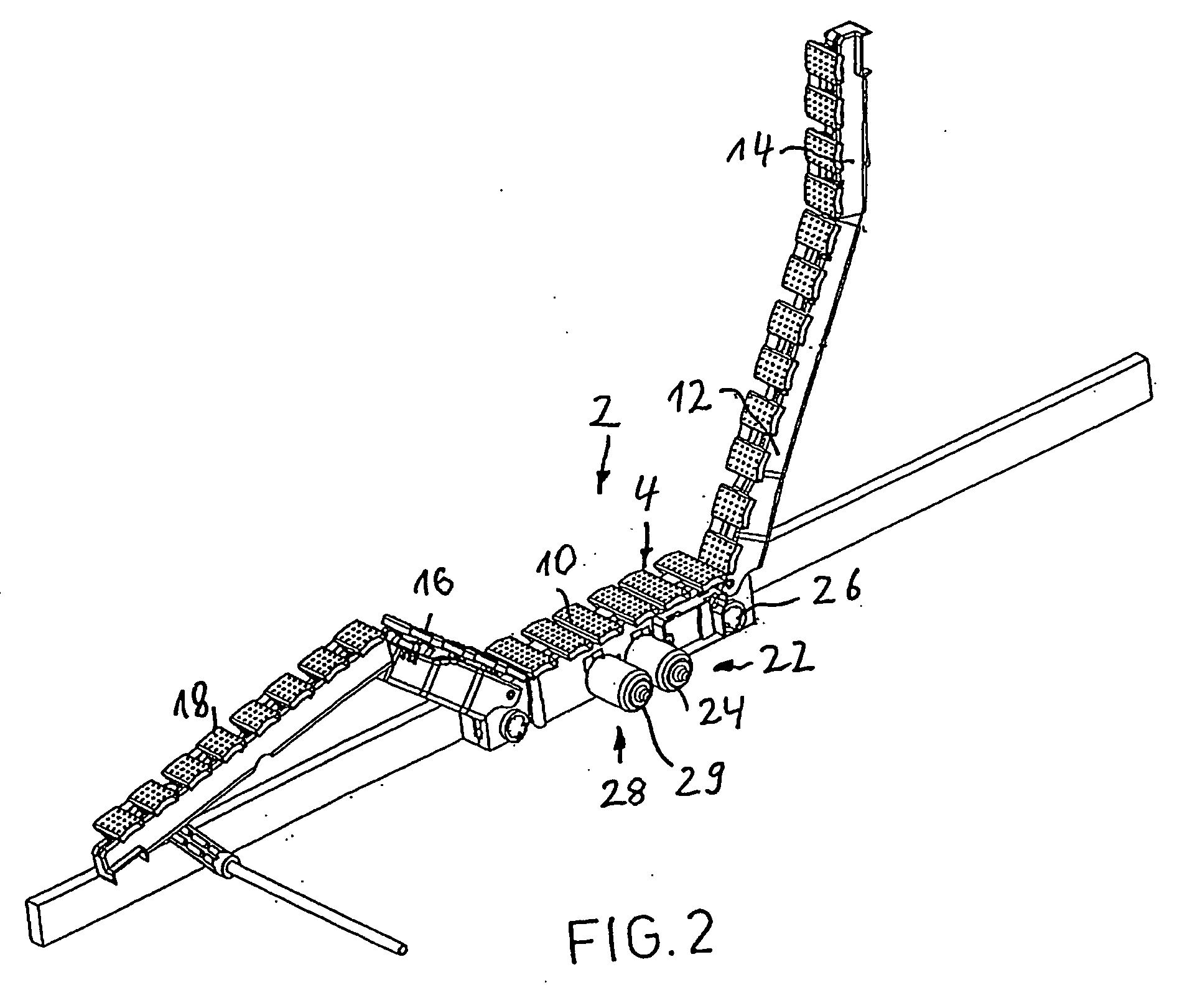

[0027] In FIG. 1, components of a modular system 2 according to the invention are illustrated, which in this exemplary embodiment includes a first longitudinal member subassembly 4 and a second longitudinal member subassembly 6, which can be detachably connected to one another via connecting elements that are not shown in FIG. 1, to form a base body for a supporting device 8, the supporting device 8 in this exemplary embodiment being configured as a slatted frame. The connecting elements for connecting the longitudinal member subassemblies 4, 6 can be formed, for example, by cross rails that connect the longitudinal member subassemblies 4, 6 and extend transversely to the longitudinal direction of the supporting device 8.

[0028] In this exemplary embodiment, the first longitudinal member subassembly 4 has a center supporting section 10, with which an upper body supporting section 12 is connected such that it can pivot around a horizontal pivoting axis; and a headrest section 14 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com