Acoustic structure of seat back

a seat back and acoustic technology, applied in the field of sound systems, can solve the problems of not being able to enjoy music satisfactorily, not being able to impart sound through, and avoiding conventional etc., to achieve the effect of improving the acoustic structure of seats, high air permeability, and high cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

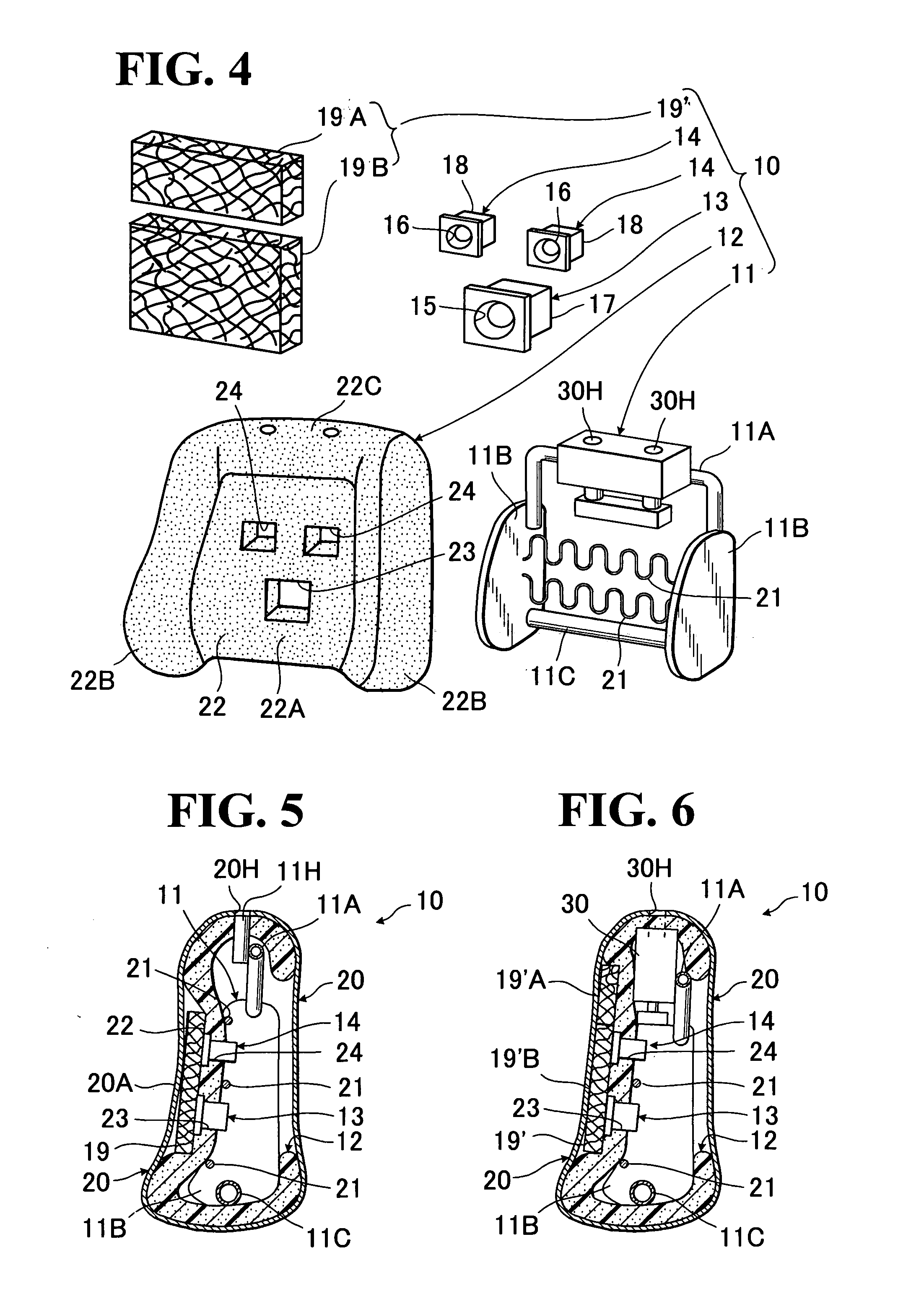

second embodiment

[0045]FIGS. 4 and 6 show a second mode of acoustic structure (10) which is suggested in connection with the effect given at the item (iv) above. This particular second embodiment is basically identical in structure to the above-described firsts mode, except that a second mode of sound-conductive cushiony plate element (19) is provided, which comprises a pair of first and second sound-conductive cushiony plate elements (19A) (19B) and that a known active headrest support mechanism (30) is mounted on the upper frame section (11A) of seat back frame (11), the active headrest support mechanism (30) being operable to cause vertical movement of a headrest (not shown). Hence, all like designations to be used hereinafter correspond to all like designations given in the foregoing first mode, and any specific description is omitted on common elements and parts between the first and second modes for the sake of simplicity.

[0046] As shown in FIG. 4, the sound-conductive cushiony plate element (...

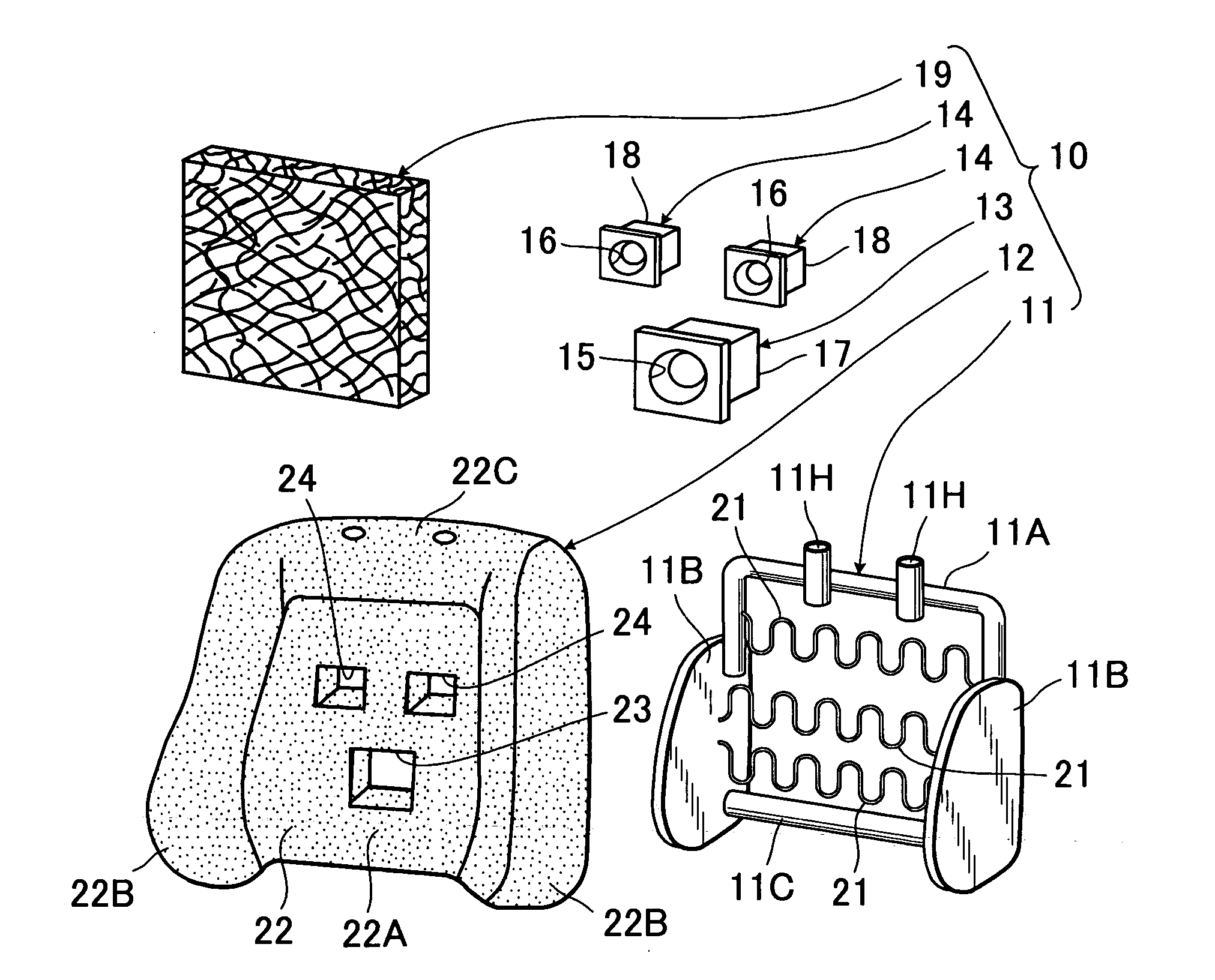

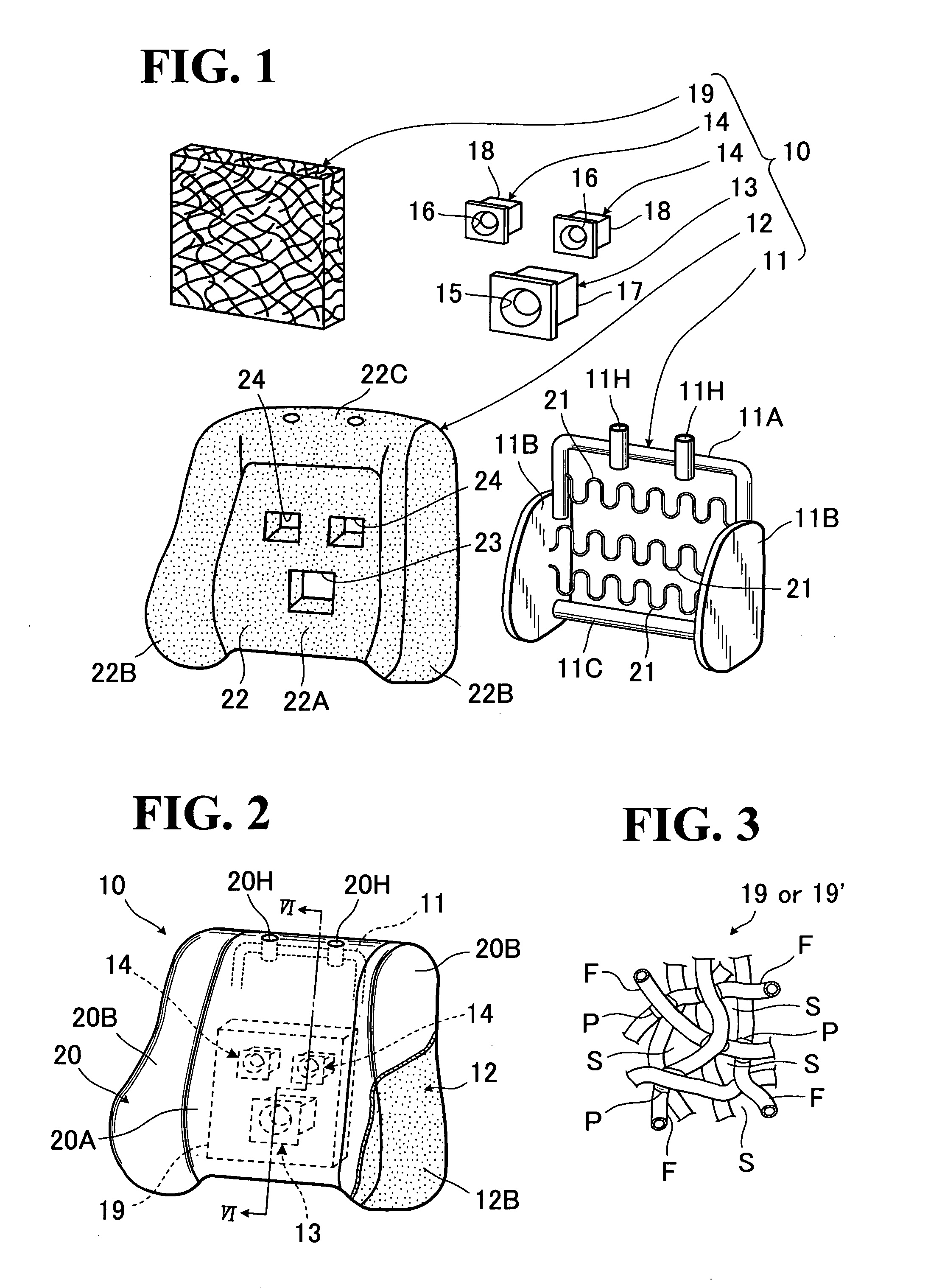

first embodiment

[0048] Likewise in the first embodiment, both two network cushiony plate members (19A) (19B) are formed from the straw-like fiber (F) bent and tangled, with a plurality points thereof are adhered to one another by means of thermal fusing, as indicated by (P), with spaces (S) given among the thus-tangled and adhered fiber (F), so as to form a network cushiony plate member having a high sound conductivity. Also, a whole of the two network cushiony plate members (19A) (19B) has a depth generally equal to the afore-stated backwardly recessed degree of the central portion (22A), and, in other words, a whole of those two members (19A) (19B) are generally equal in dimensions to the recessed central frontal backrest surface area (22A) of foam padding (22).

[0049] As shown in FIG. 6, the first and second network cushiony plate members (19A) (19B) are juxtaposed on and secured to a whole area of the central portion (22A) of foam padding (22) so as to overlie all the speaker units (14) (18). In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com