Fence system with pultruded rail sections

a technology of pultruded rail sections and fencing systems, which is applied in the direction of building types, constructions, building constructions, etc., can solve the problems of difficult to provide high-strength structural members, thin decorative layers of such structural members, and easy scratching or wear of the surface of such structural members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

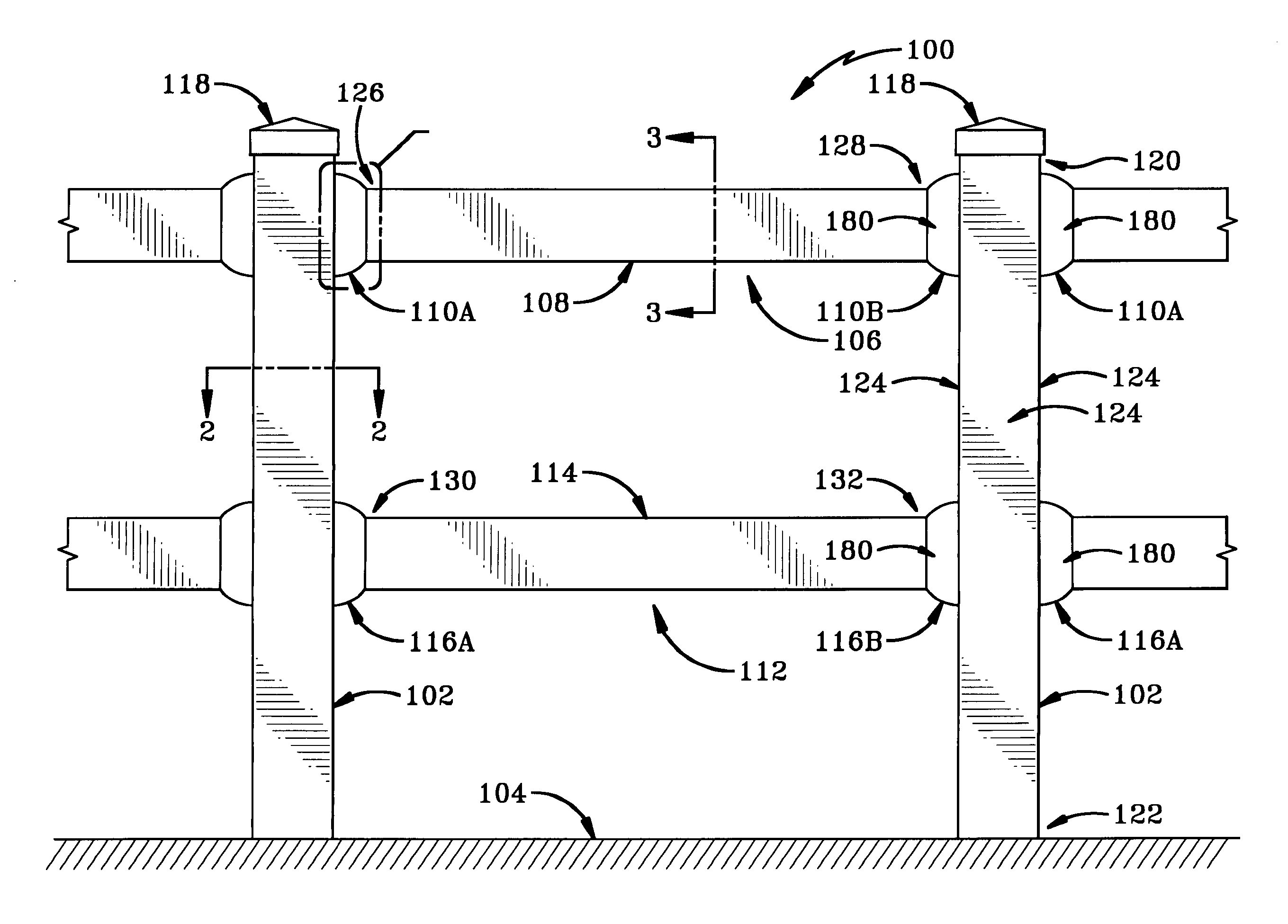

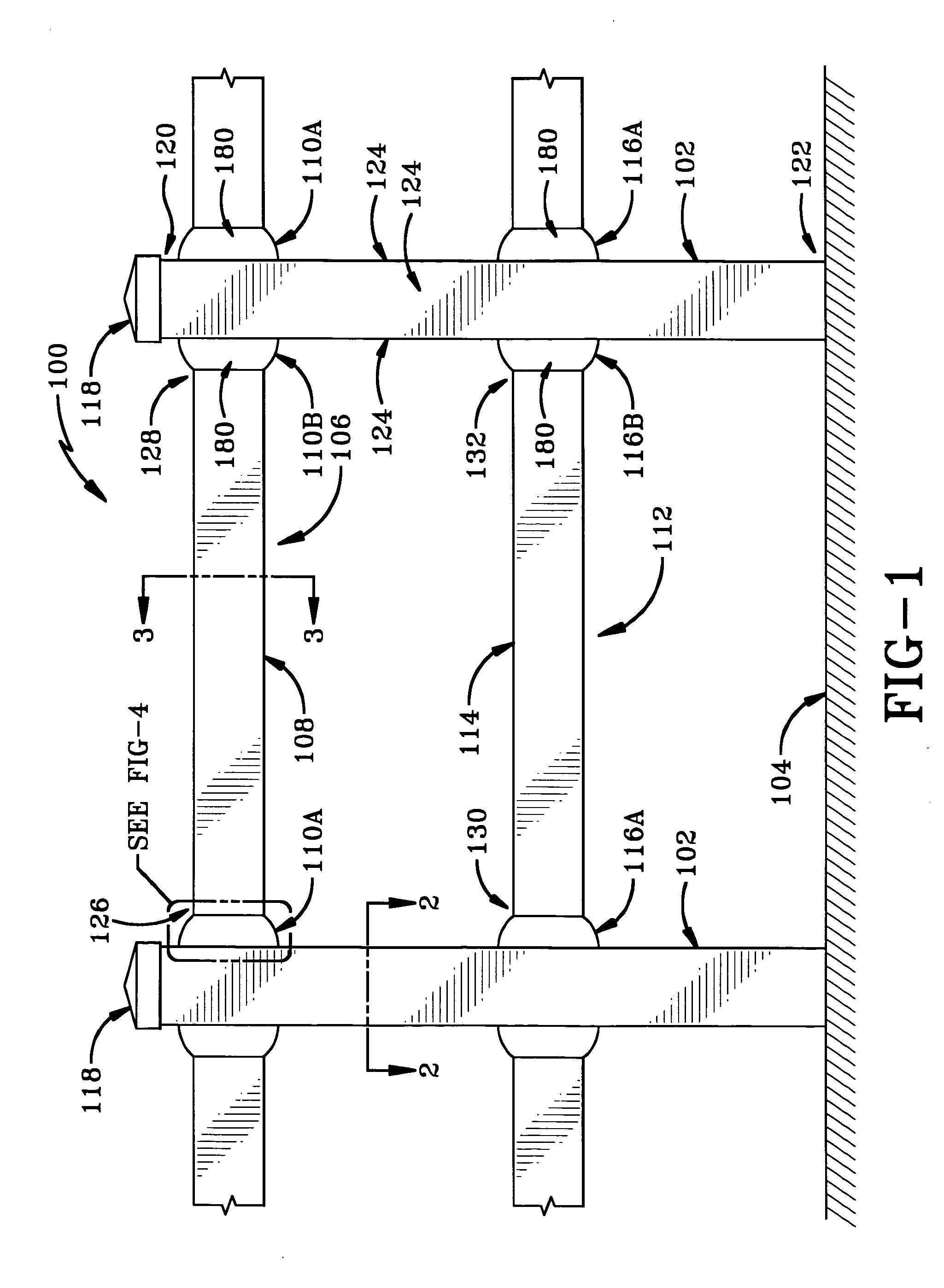

[0015] A first embodiment of the fence system of the present invention is indicated generally at 100 in FIG. 1 and a second embodiment is indicated generally at 200 in FIG. 6. Fence system 100 includes a pair of posts 102 which are adapted to mount on a foundation 104 such as the ground, a floor, or any of various types of platforms. System 100 further includes an upper rail structure 106 including an upper rail 108 and a pair of upper rail mounting brackets 110A and 110B mounted on each post 102. System 100 further includes a lower rail structure 112 including a lower rail 114 and a pair of lower rail mounting brackets 116A and 116B mounted on each post 102. A cap member 118 is seated atop each post 102.

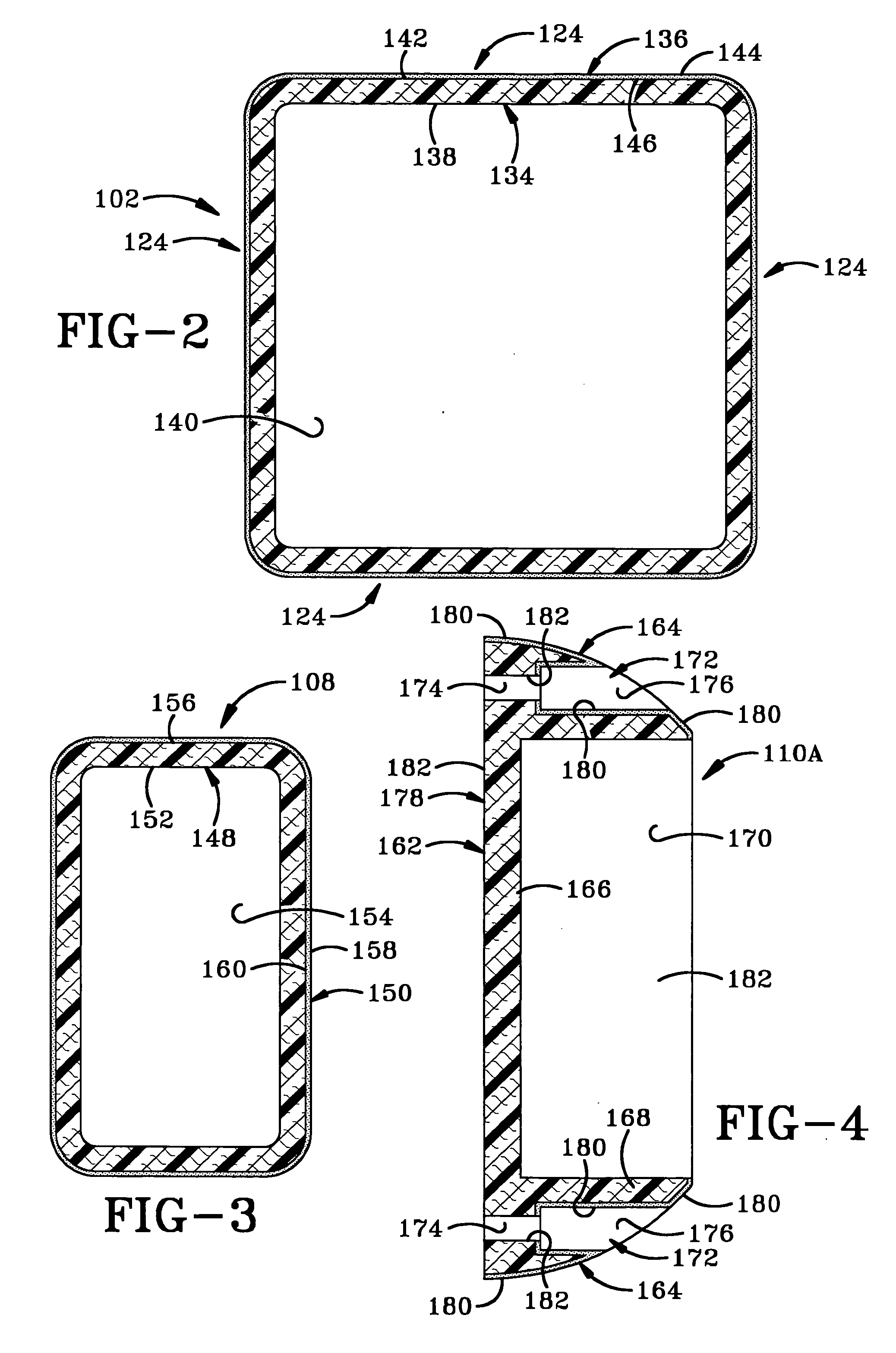

[0016] Each post 102 (FIG. 1) has an upper end 120 and a lower end 122 adjacent which post 102 is mounted on foundation 104. Each post 102 is hollow and elongated in a vertical direction between upper end 120 and lower end 122. Each post 102 has four substantially flat sides 124 (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com