Growth medium for sphagnum moss

a technology of sphagnum moss and growth medium, which is applied in the field of cultivating base for sphagnum, can solve the problems of reducing the number of animals and plants which can survive only in sphagnum bogs, affecting the survival of animals and plants, and not being suitable for cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0182] The present invention will next be described by way of Examples.

[The Sphagnum Cultivation Base According to the First Embodiment]

[0183] (1) Old newspaper (4 g) was shredded in water (500 mL) and then kneaded thoroughly. The kneaded product was mixed with dried sphagnum plants (a commercially available product for gardening; boiled) (100 g, dry base), and water (3 L) was added thereto, thereby preparing, from shredded paper, a water-containing composition containing dried sphagnum plants.

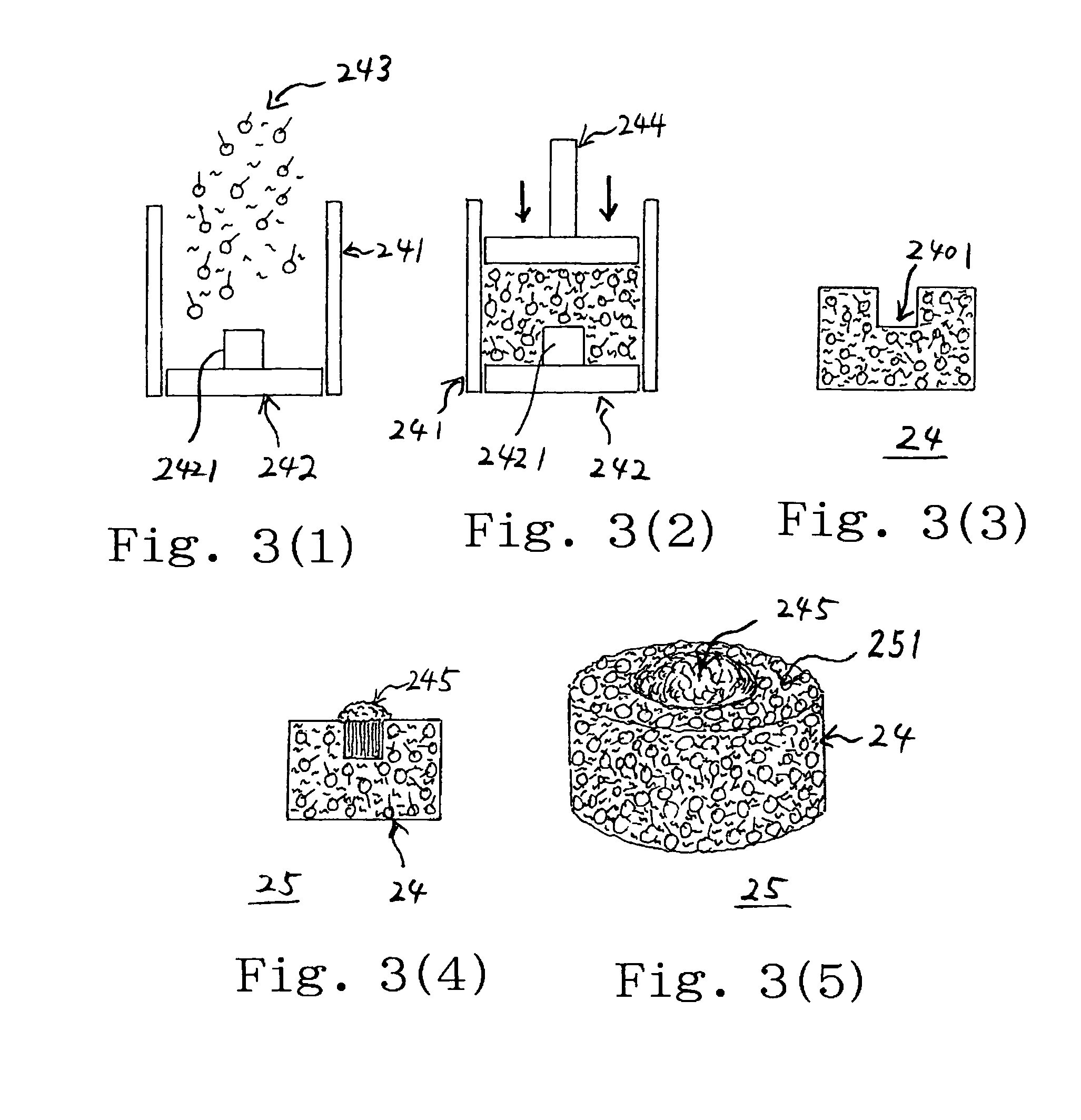

[0184] (2) The water-containing composition (about 1 kg) was processed in a manner shown in FIGS. 3 (1) to (5), to thereby produce a dried-sphagnum molded product forming a cylinder (height: about 8 cm, diameter at bottom: about 15 cm) and having a depression (diameter: about 3 cm, depth: about 5 cm) at a center portion of one bottom of the cylinder. Separately, a bunch of live sphagnum (about 2 g, dry base) was prepared by use of Sphagnum palustre L. plants obtained in large-scale cultivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com