Method for making a stressed structure designed to be dissociated

a stress structure and stress technology, applied in the direction of basic electric elements, semiconductor/solid-state device manufacturing, electric apparatus, etc., can solve the problems of high internal stress, damage to the structure, and damage to at least one of these two structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

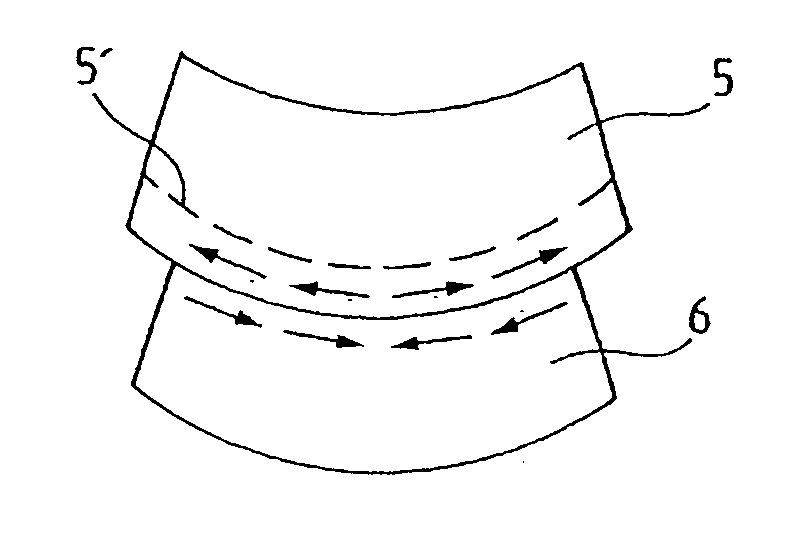

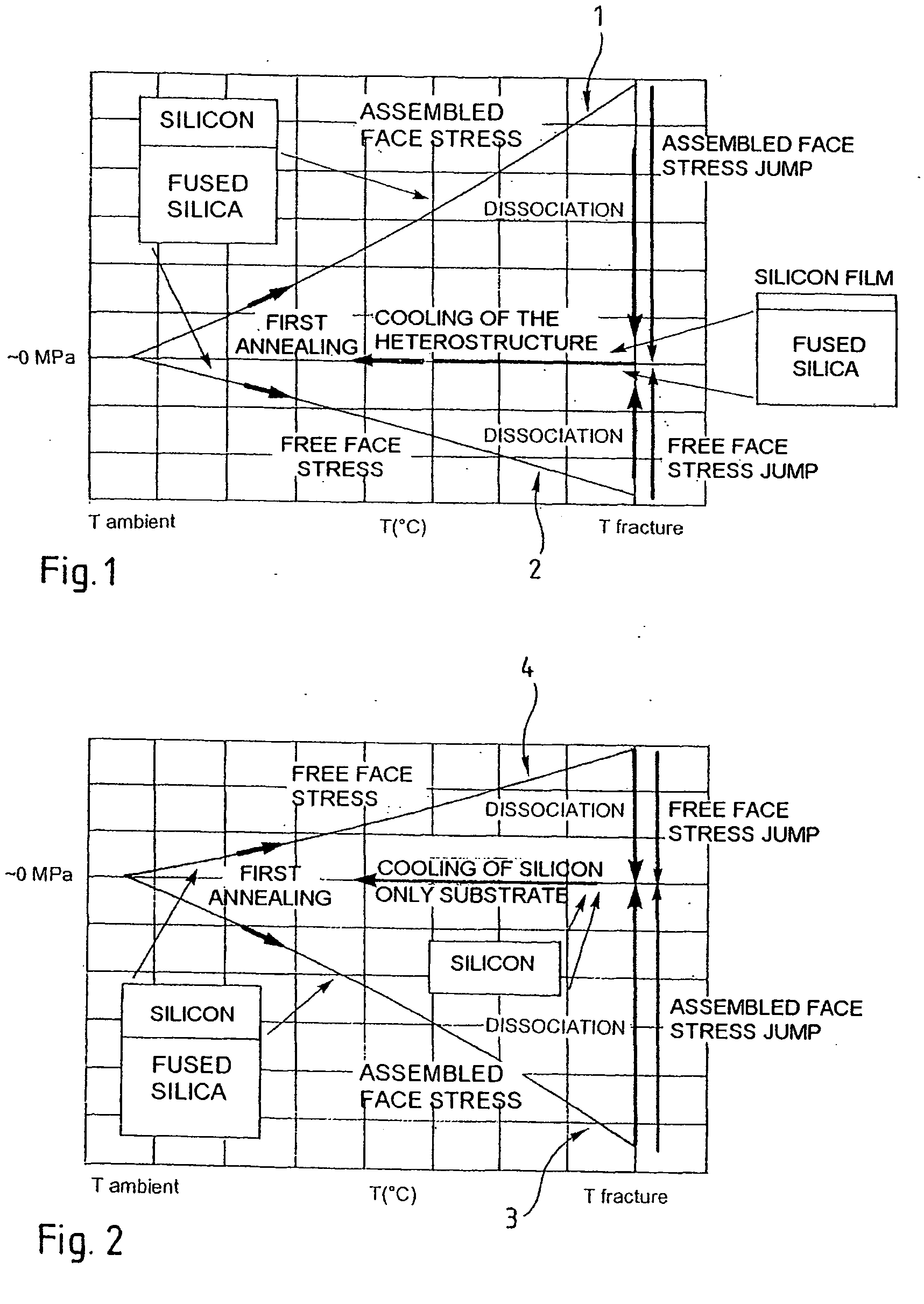

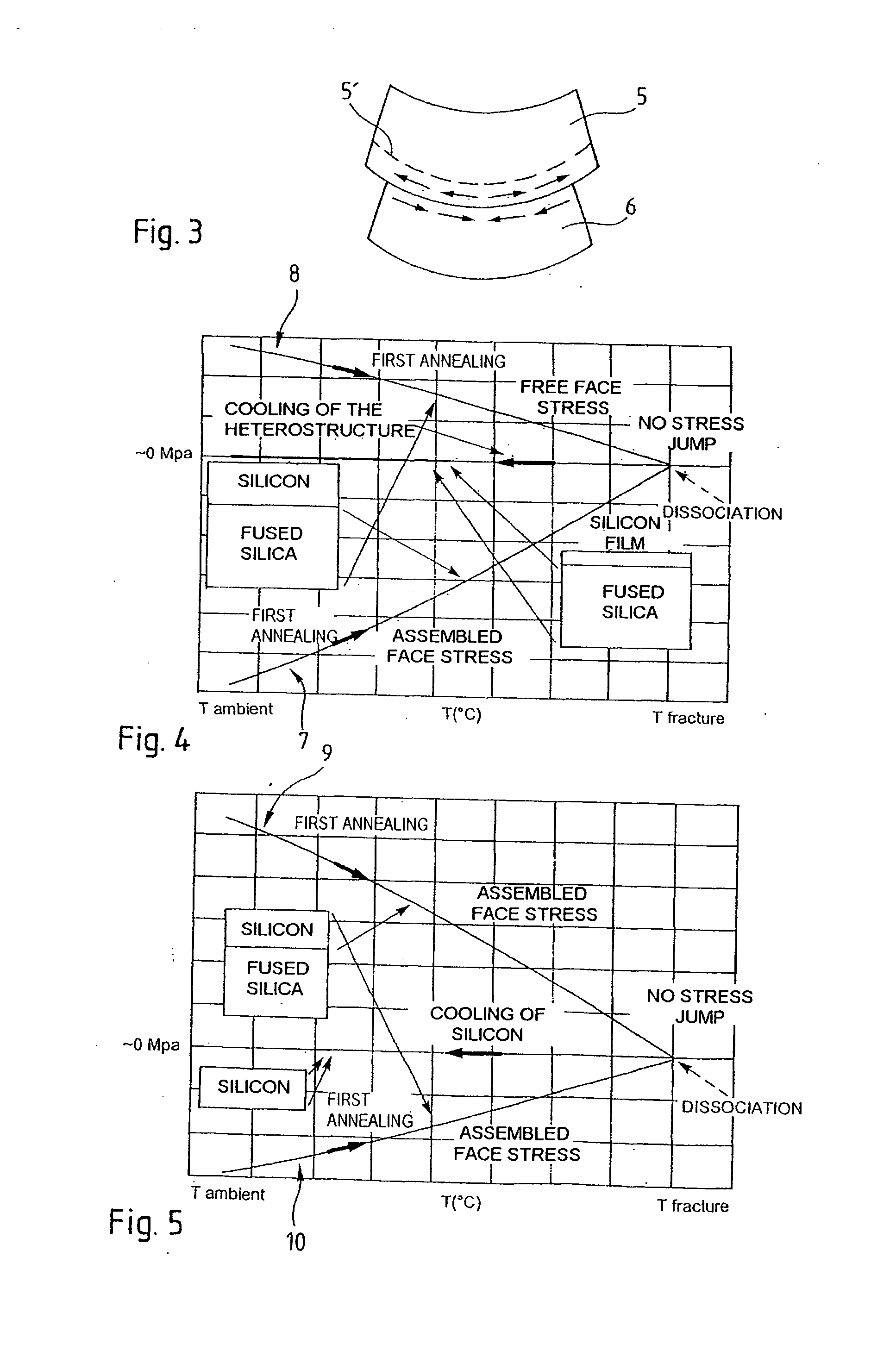

[0057] In the figures to which the following description refers, identical, similar or equivalent parts are identified by the same reference numbers. Also, to clarify the figures, the various items are not represented to a consistent scale.

[0058] To illustrate the invention, there will be described by way of non-limiting example a method of transferring a film consisting of a layer of silicon approximately 0.4 μm thick and a layer of oxide approximately 0.4 μm thick from a 200 mm diameter surface-oxidized silicon source substrate 750 μm thick to a 200 mm diameter fused silicon target substrate 1200 μm thick.

[0059] The film may be transferred using the following method, employing standard transfer techniques:

[0060] ionically implanting the source substrate to create within that substrate a weakened region that delimits the thin layer to be transferred under implantation conditions known to the person skilled in the art, for example hydrogen implantation at a dosage of approximatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com