Foundations for constructions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

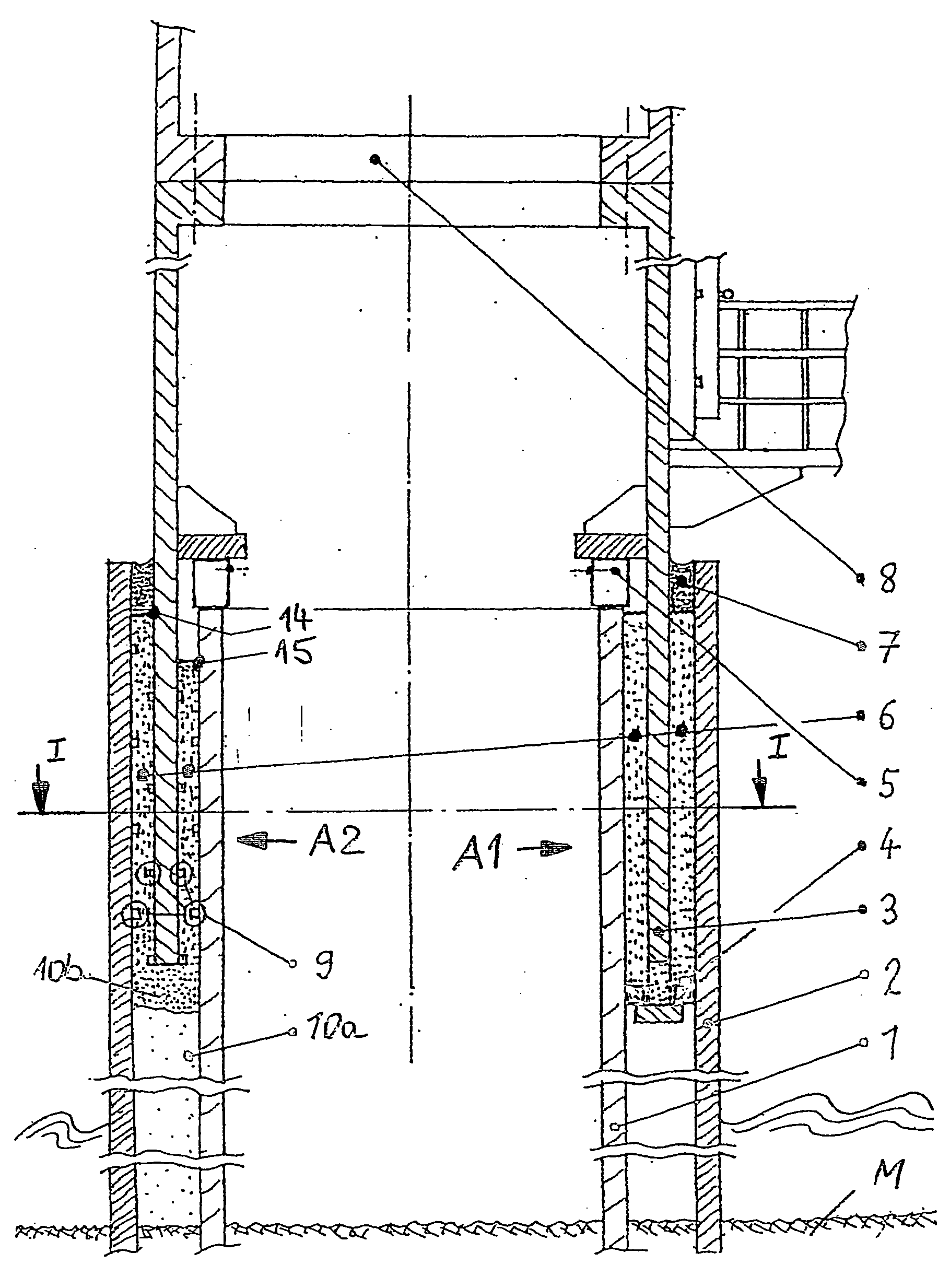

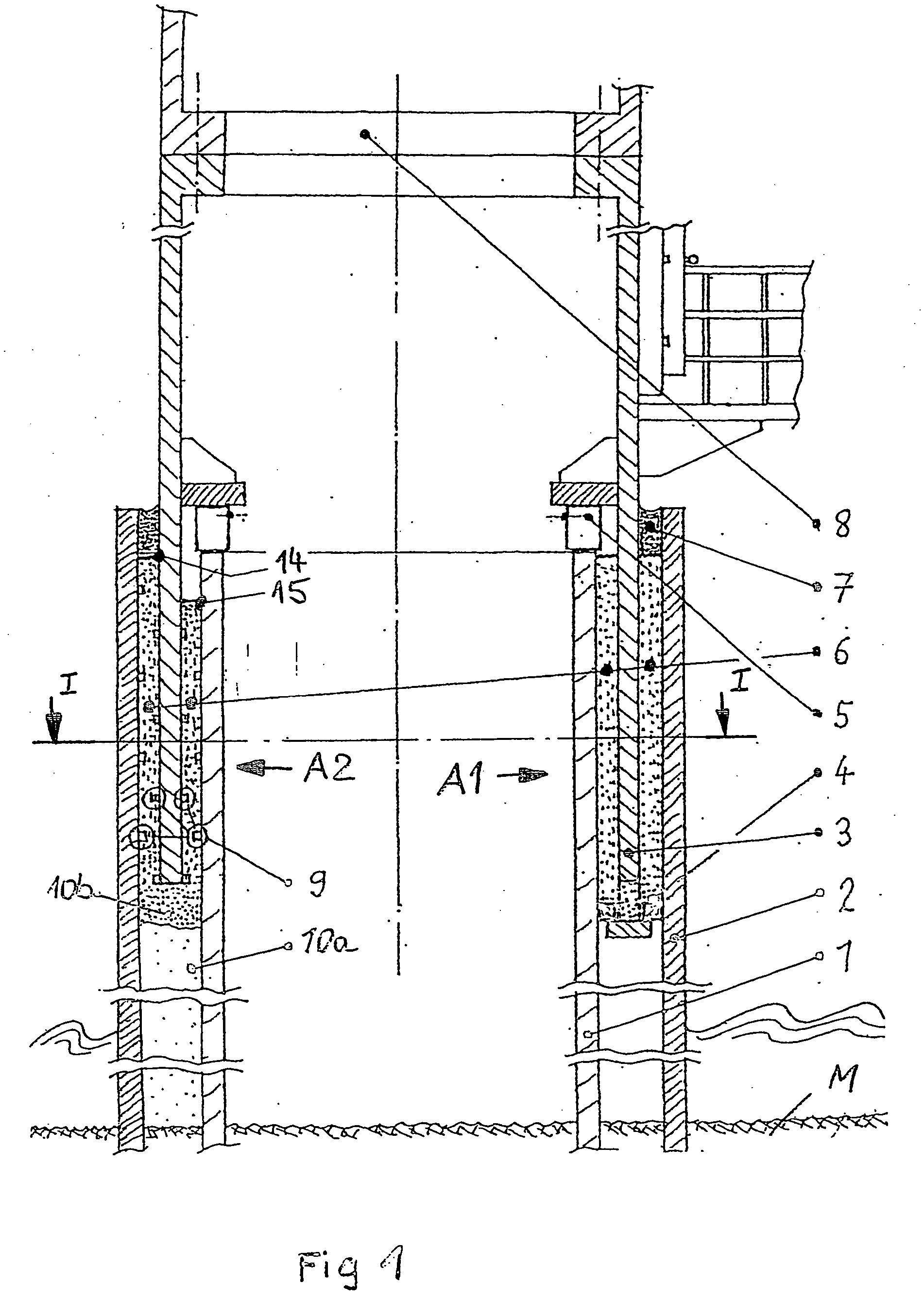

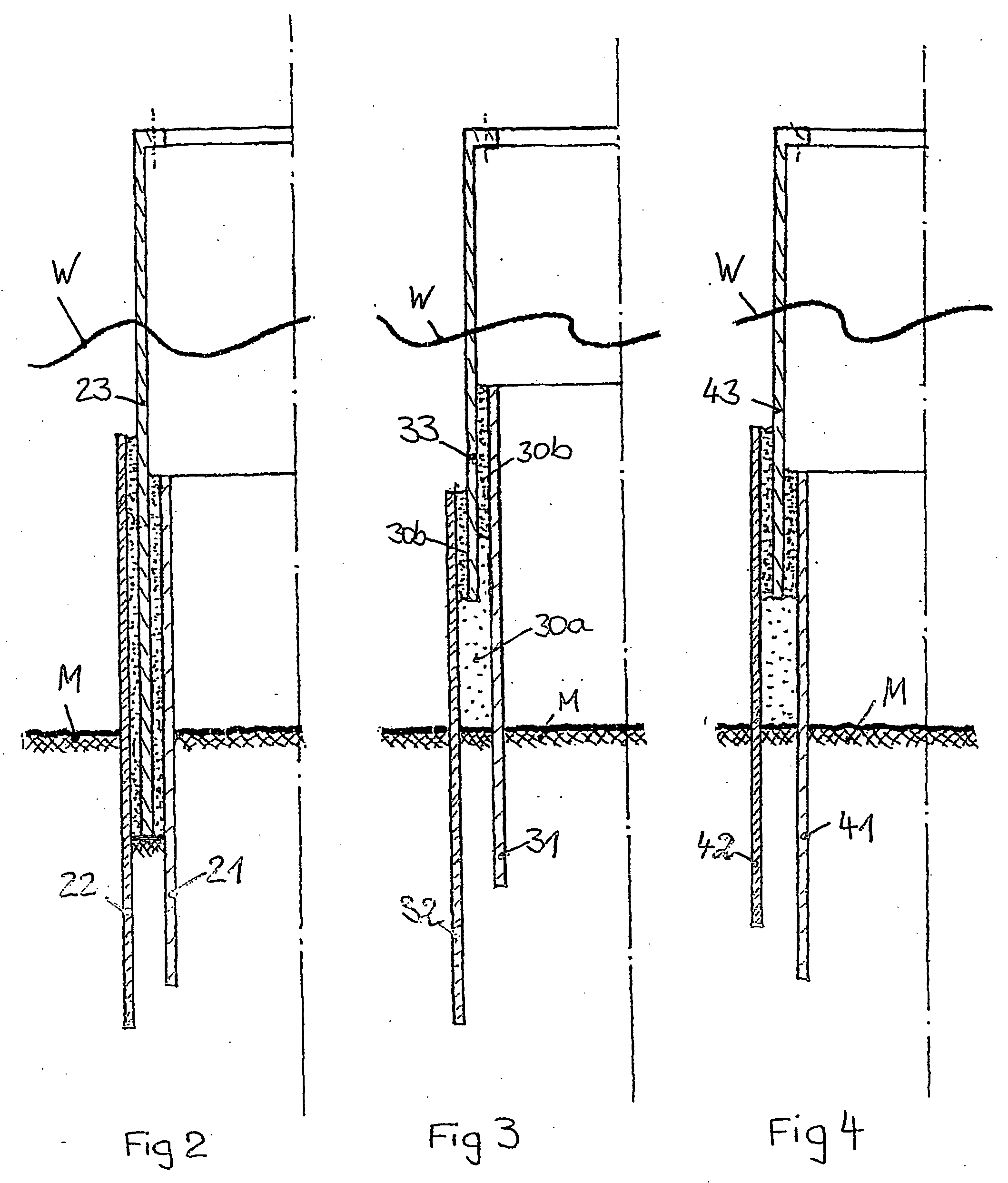

[0052] Two different embodiments A1 and A2 of the invention, which in reality are usually of rotationally symmetrical design, are shown to the left and to the right of the vertical dash-dot line of symmetry. However, in the case of wind power installations which are exposed to high winds or high waves, for economic reasons, it may also be sensible to use different filling material over the circumference of the pile according to the prevailing direction of the high winds or high waves (e.g. inexpensive gravel in the secondary loading direction and high-grade filling material, e.g. grout, in the main loading direction).

[0053] An inner tube 1 and an outer tube 2 are introduced into the seabed (M). The junction piece 3, which is provided at the upper end with a conventional screw flange as connection to the rest of the construction 8, is pushed into the gap between the inner tube 1 and the outer tube 2.

[0054] In the embodiment A1, on the right-hand side only, the region of the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com