Stable emulsions of oils in aqueous solutions and methods for producing same

a technology of oil in water solution and stable emulsion, which is applied in the direction of oil/fat/waxes non-active ingredients, plant/algae/fungi/lichens ingredients, food ingredients for microorganism protection, etc., can solve the problems of protein destabilization by its conformational change, emulsion is very unstable,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

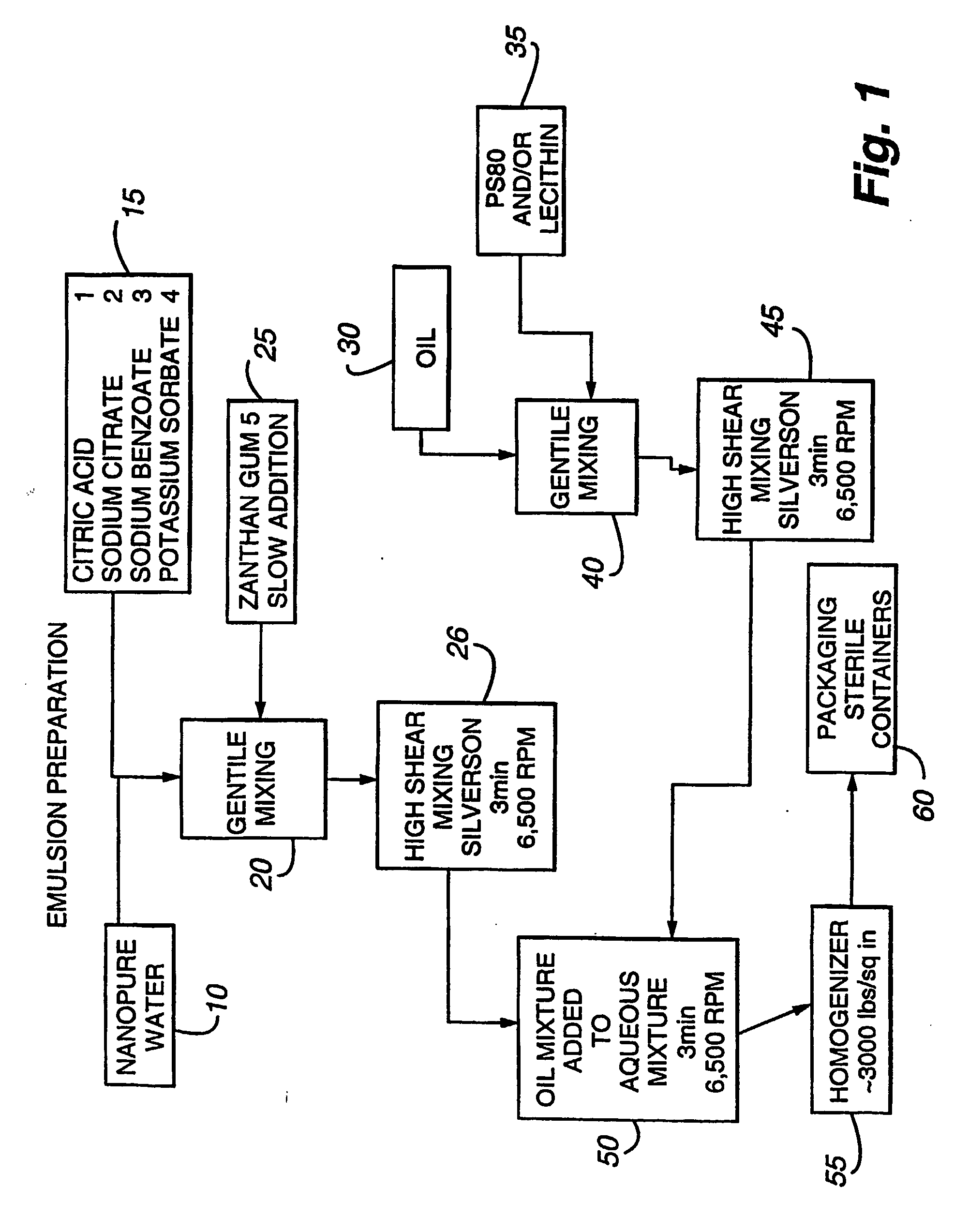

Image

Examples

example 1

[0046] This example illustrates the preparation of an emulsion of the present invention, and its stability over time and when used in a food application.

[0047] A total of 75 grams of DHA-rich oil (DHA GOLD™ oil) extracted from the marine microorganism Schizochytrium sp. was added to 25 grams of polysorbate 80. The solution was heated to 60° C. for five minutes and mixed to dissolve the polysorbate. In a separate flask, 150 mg xanthan gum was mixed with 25 grams of water and vortexed. A new solution was made by taking 5 grams of the DHA GOLD oil / polysorbate solution and mixing with the entire 25+ grams of the water / xanthan gum solution. The new mixture was mixed and then heated at 60° C. for 1 minute to form the emulsion. The resulting mixture was stored in a refrigerator (4° C.) for 30 days. At the end of 30 days, no phase separation of the oil was observed. Odor evaluation of the emulsion indicated no formation of fishy odors—the emulsion was essentially odorless.

[0048] To test t...

example 2

[0049] This example illustrates the composition of a lecithin based emulsion of the present invention in Table 1.

TABLE 1Lecithin Based EmulsionComponentWt. PercentDHASCO-S ®*: DHA-containing oil27.91Polysorbate 800.30Lecithin4.63Citric Acid Buffer (0.025M)65.66Xanthan Gum0.43Sodium Benzoate0.05Potassium Sorbate0.05TOTAL100.00

*Registered trademark of Martek Biosciences Corporation

example 3

[0050] This example illustrates the composition of a polysorbate based emulsion of the present invention in Table 2.

TABLE 2Polysorbate Based EmulsionComponentWt. PercentDHASCO-S ®: DHA-containing oil27.91Polysorbate 804.92Citric Acid Buffer (0.025M)66.56Xanthan Gum0.43Sodium Benzoate0.05Potassium Sorbate0.05TOTAL100.00

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com