Packaging body

a packaging body and body technology, applied in the field of packaging units, can solve the problems of time-consuming, complicated unsealing operation, and unsatisfactory conventional packaging units from the standpoint of tamper-proofness, and achieve the effects of simple and inexpensive, enhanced tamper-proof effect, and quick and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

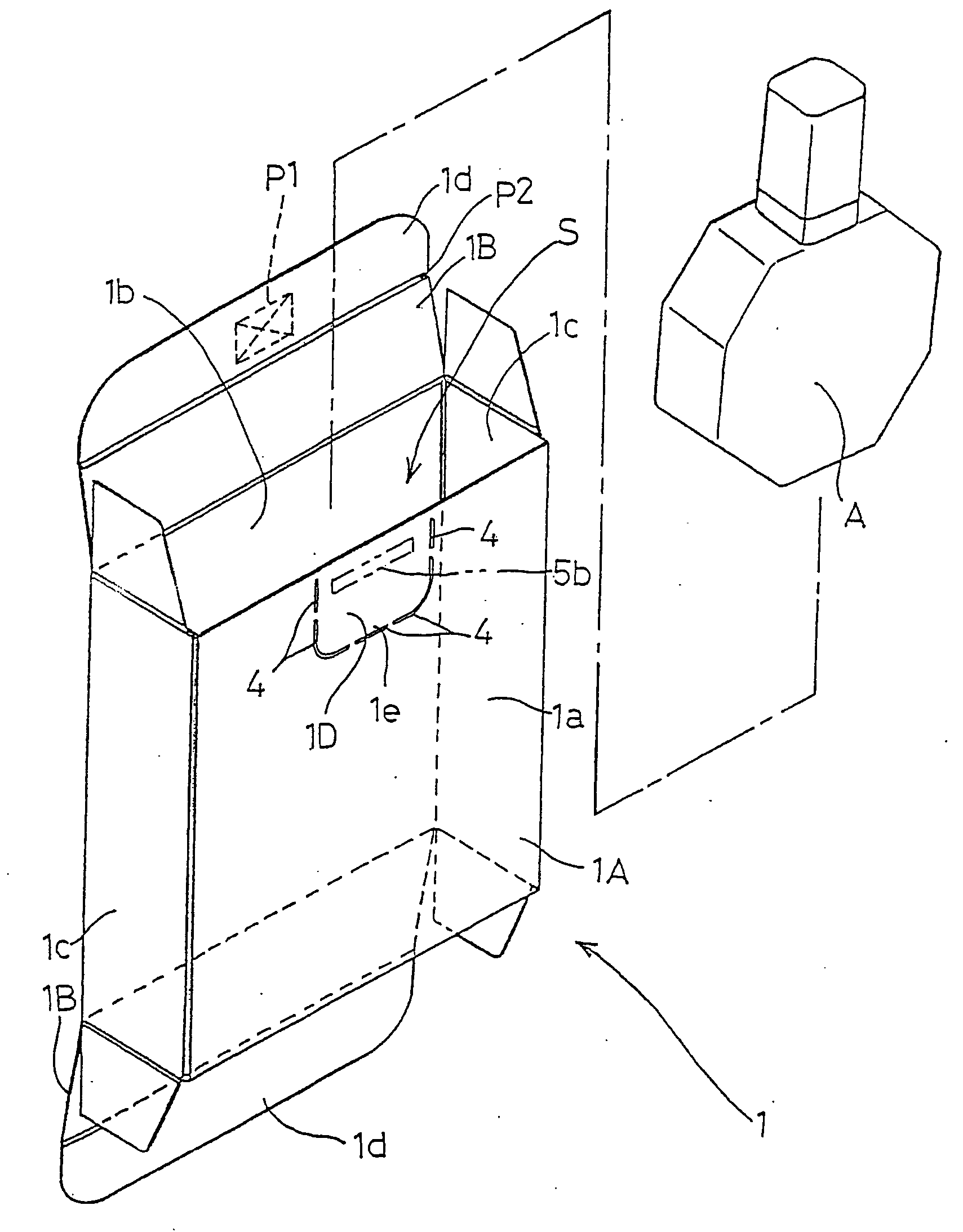

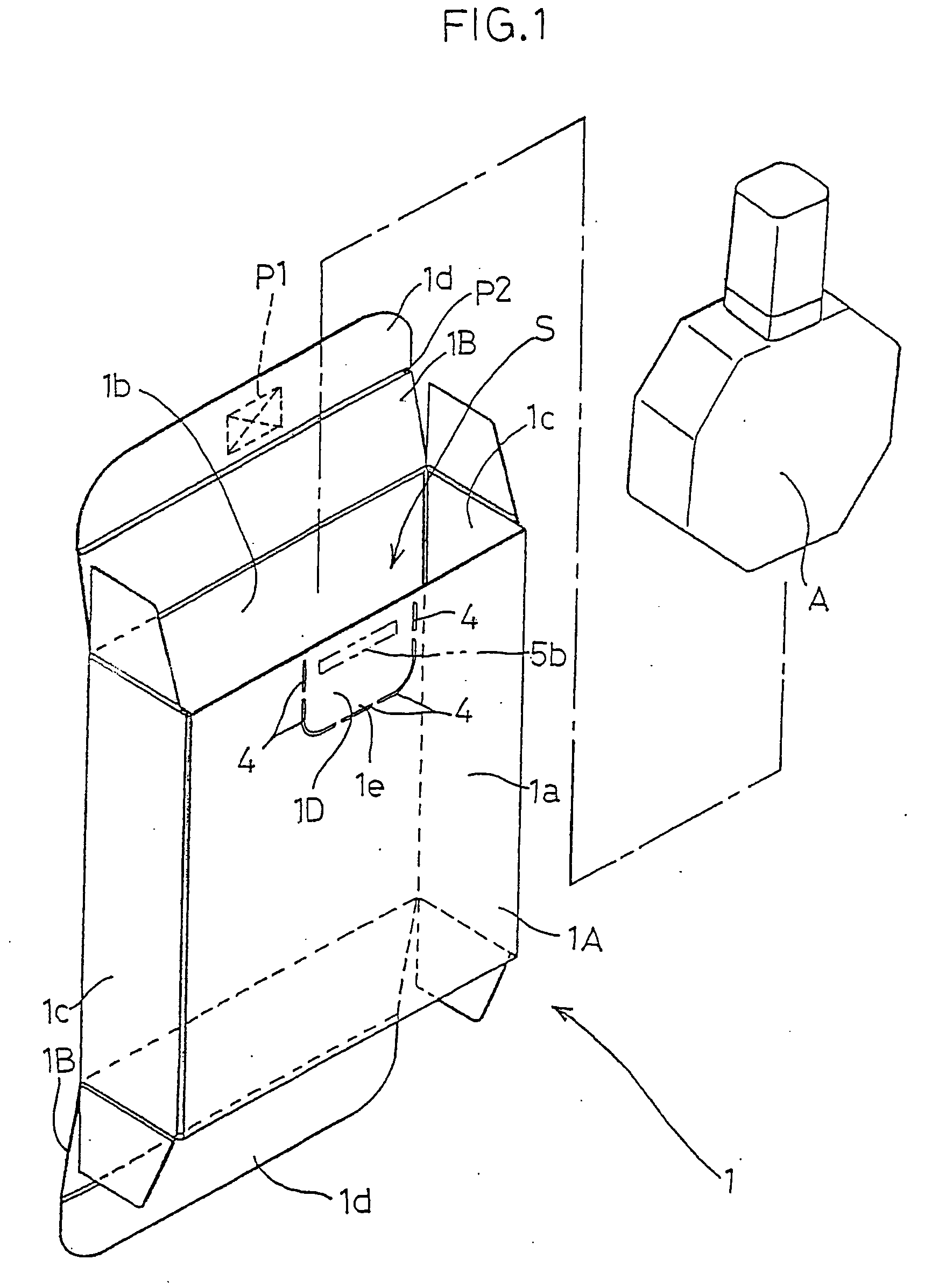

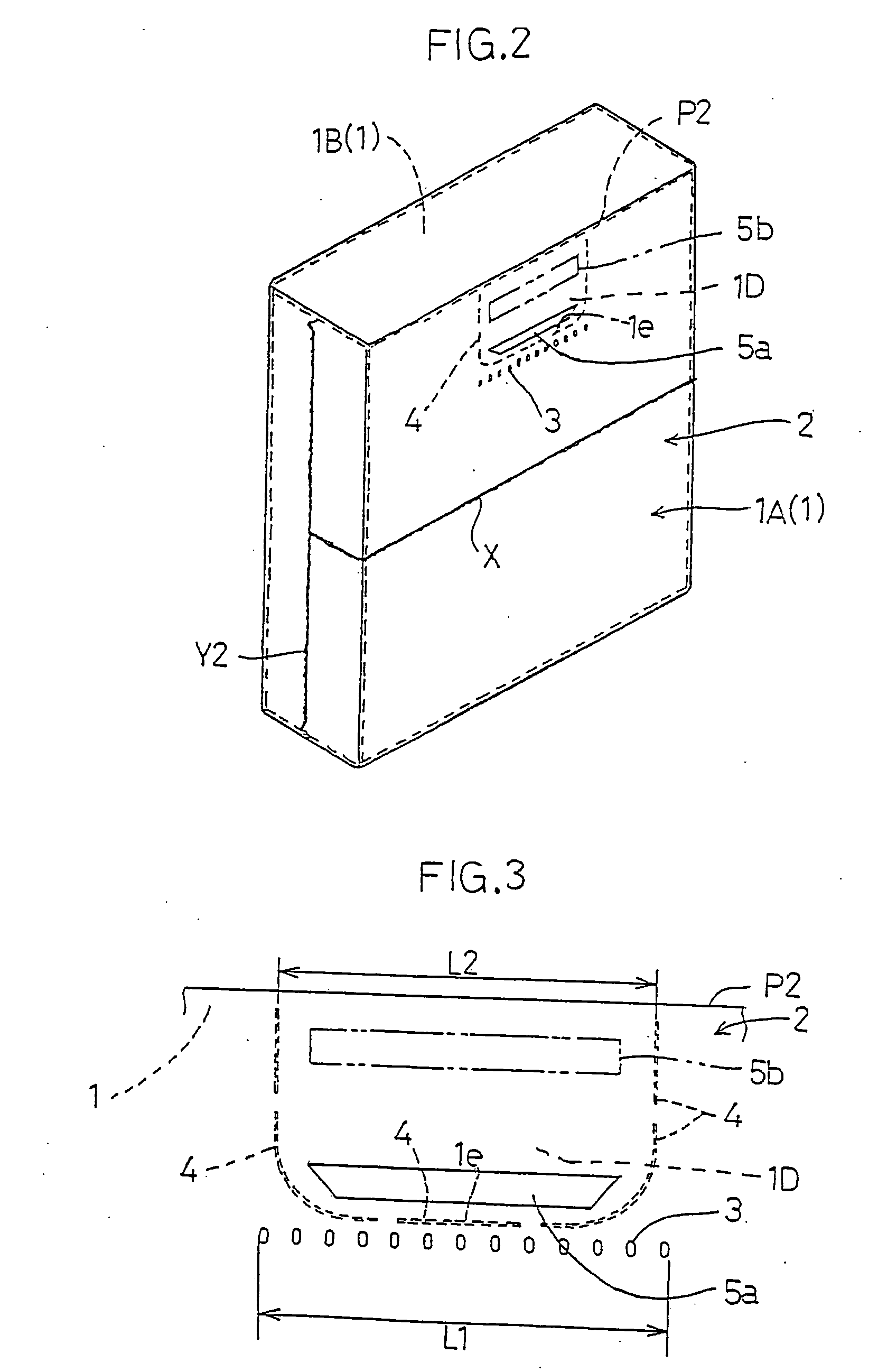

[0051]FIGS. 1 through 5 show a packaging unit for receiving a product A such as an eyedropper, the packaging unit including a paper package box 1 having an openable portion 1D for breaking and removing a seal of a lid 1B by a push-in operation, and a film 2 for sealing and packing entire surfaces of the package box 1. The film 2 defines a fragile portion 3 in or adjacent a position corresponding to the openable portion 1D of the package box 1, which is tearable by a push-in operation effected on the openable portion 1D from outside the film 2.

[0052] More particularly, as shown in FIG. 1, the package box 1 comprises a quadrangle tubular box body 1A consisting of a pair of front and back sidepieces 1a and 1b and a pair of right and left sidepieces 1c to define a storage space S for receiving the product A, and lids 1B formed integrally with vertically (axially of the tube) opposite ends of the back sidepiece 1b, respectively, for freely opening and closing two openings of the package...

second embodiment

[0059] In a packaging unit according to a second embodiment of the present invention, as shown in FIG. 6, a heat shrinkable film 2 includes perforations constituting a fragile portion 3 perforations formed in a position corresponding to an edge 1e of a punch-out portion 1D and linearly parallel or substantially parallel to the edge 1e of the punch-out portion 1D which is displaced to a maximum extent in time of a push-in operation, i.e. a deep end edge 1e remotest from a boundary P2 between a lid 1B and an insert piece 1d. The perforations 3 formed in the heat shrinkable film 2 has the same or substantially the same length L1 as a width L2 of the punch-out portion 1D of the package box 1.

[0060] The other aspects of the construction are the same as in the first embodiment, and like reference numbers are affixed to like elements in the first embodiment and will not be described here.

third embodiment

[0061] In a packaging unit according to a third embodiment of the present invention, as shown in FIG. 7, a heat shrinkable film 2 includes perforations constituting a fragile portion 3 formed in a position adjacent and inwardly of an edge 1e of a punch-out portion 1D and linearly parallel or substantially parallel to the edge 1e of the punch-out portion 1D which is displaced to a maximum extent in time of a push-in operation, i.e. a deep end edge 1e remotest from a boundary P2 between a lid 1B and an insert piece 1d. The perforations 3 formed in the heat shrinkable film 2 has a length L1 slightly smaller than a width L2 of the punch-out portion 1D of the package box 1.

[0062] The other aspects of the construction are the same as in the first embodiment, and like reference numbers are affixed to like elements in the first embodiment and will not be described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length L3 | aaaaa | aaaaa |

| width L2 | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com