Ambidextrous magazine catch for firearms

a magazine catch and firearm technology, applied in the direction of weapons, weapon components, safety arrangements, etc., can solve the problems of difficult complicated installation or “retro-fitting” of the assembly, and still fails to provide the shooter with the magazine, etc., to achieve quick and easy installation, less susceptible to snagging by foliage and battlefield obstacles, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

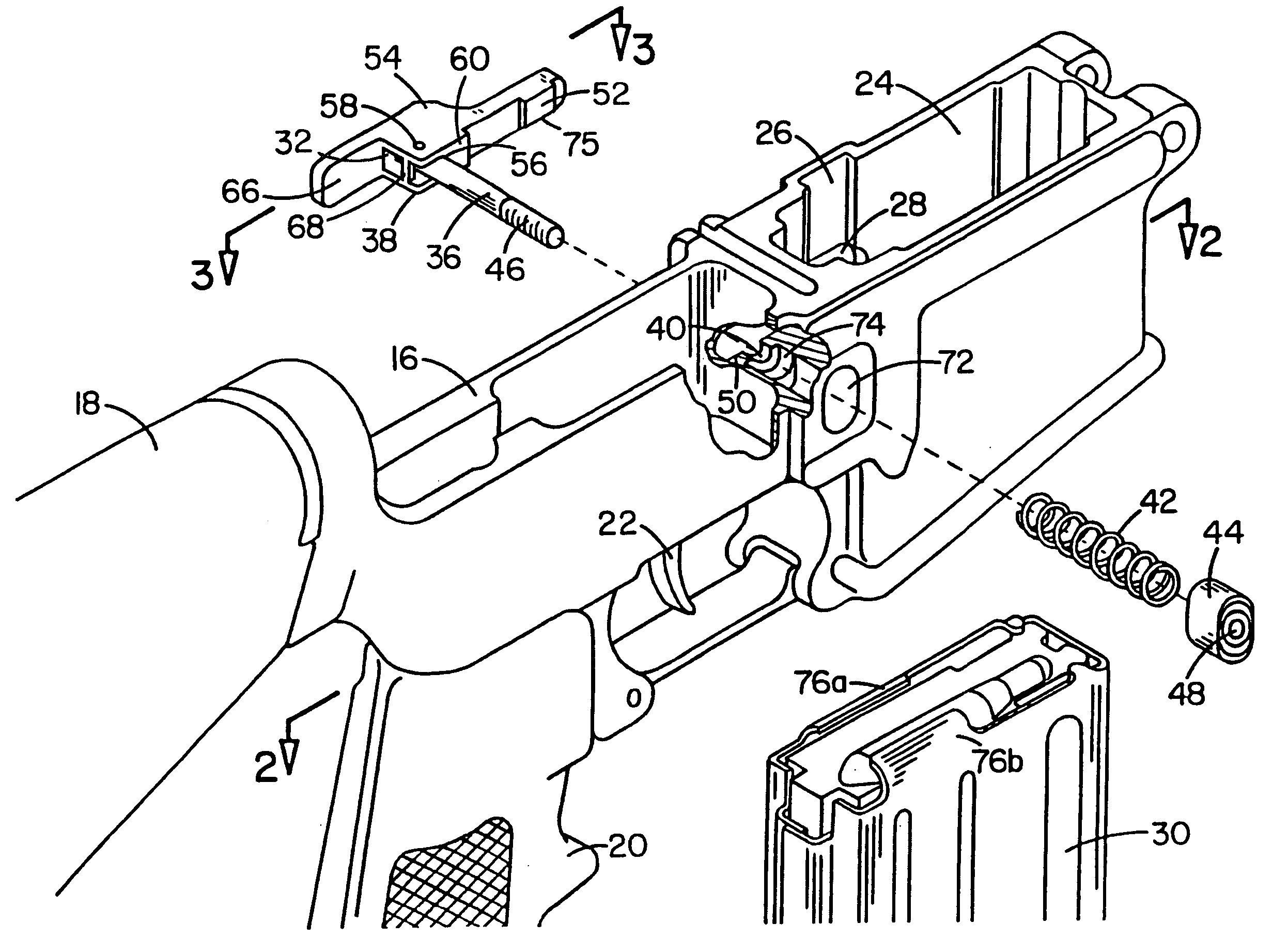

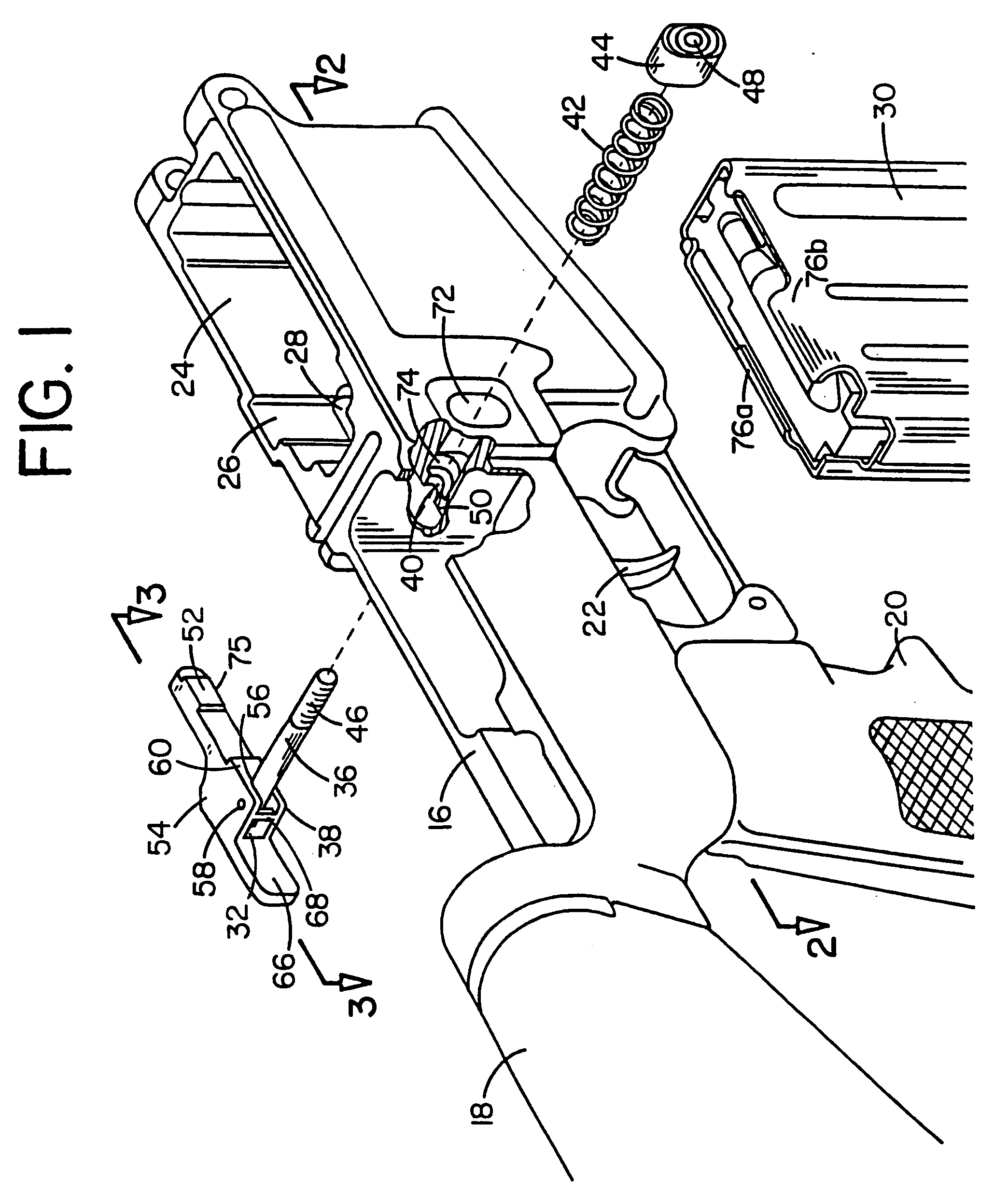

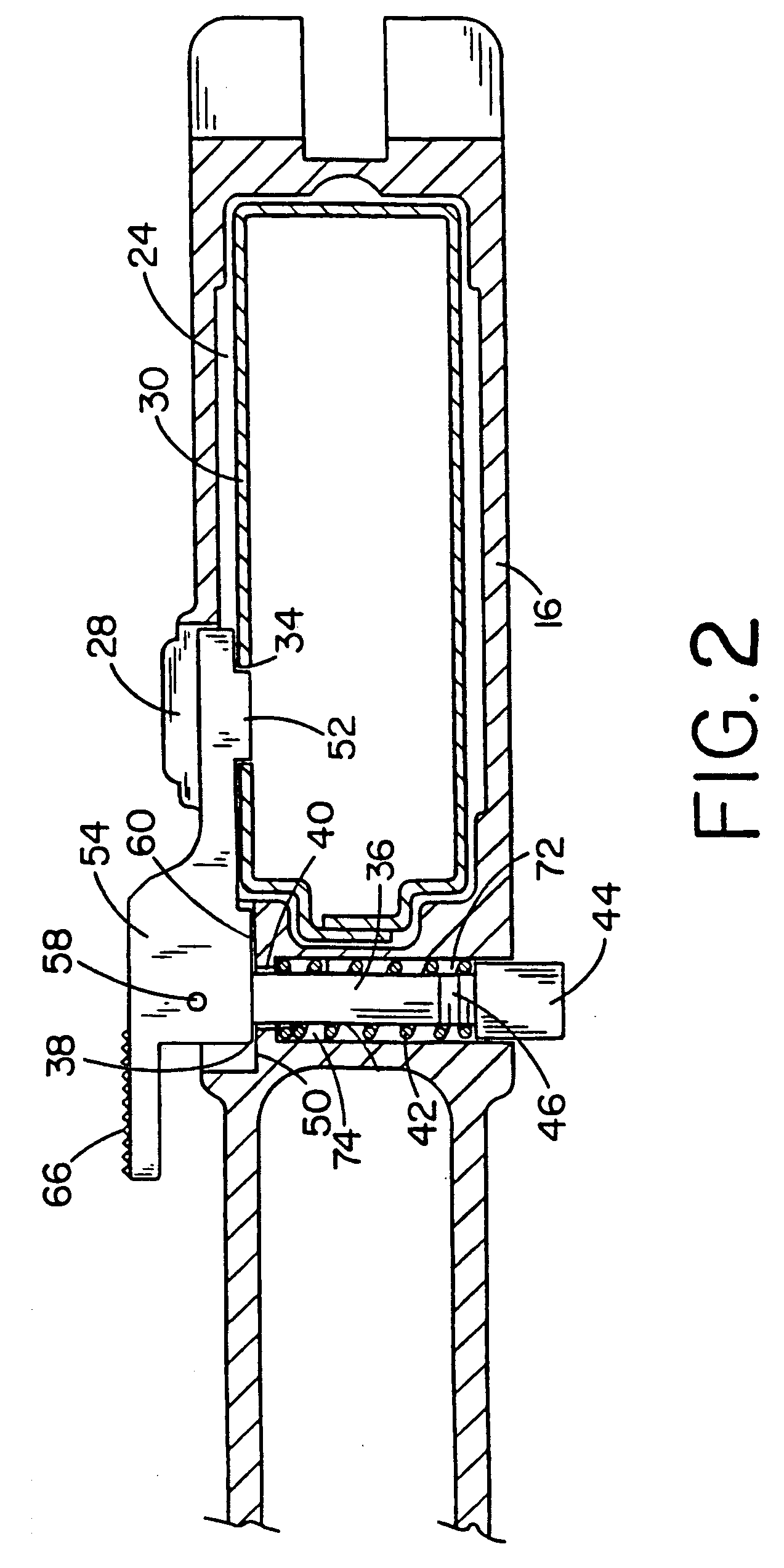

—FIG. 1

[0056] In FIG. 1 a lower receiver or body 16 of an automatic or semi-automatic rifle is shown including a buttstock 18, a pistol grip 20, a trigger 22, and a magazine well 24. Within magazine well 24 is an alignment recess 26 and an adjacent magazine catch slot 28. A magazine 30 is inserted into magazine well 24. When magazine 30 is fully seated in magazine well 24, a lateral securing slot 34 coincides with magazine catch slot 28. A shaft or rod 36, which is pivotally attached to lever 54 by means of a pin 58, is guided transversely through an orifice 40, a spring 42, and is connected to an operating push button 44 by means of a threaded portion 46 which is screwed into a threaded hole 48 extending through operating push button 44. Spring 42, acting against operating push button 44 and spring cavity 74, urges lever 54 towards body 16 within magazine catch slot 28. Lever seat 60 of lever 54 comes to rest on a seat 50 allowing for the engagement of a tooth 52, of lever 54, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com