Self-adhering spacer

a self-adhering, spacer technology, applied in the direction of roofs, building materials handling, construction, etc., can solve the problems of little in the way of mass production methods, little in the way of hand labor, and the development of tools and equipment, other than electrical power tools, permit those engaged in the building construction trade to work more quickly and efficiently, and achieve quick and easy spacing, positioning and alignment of construction materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

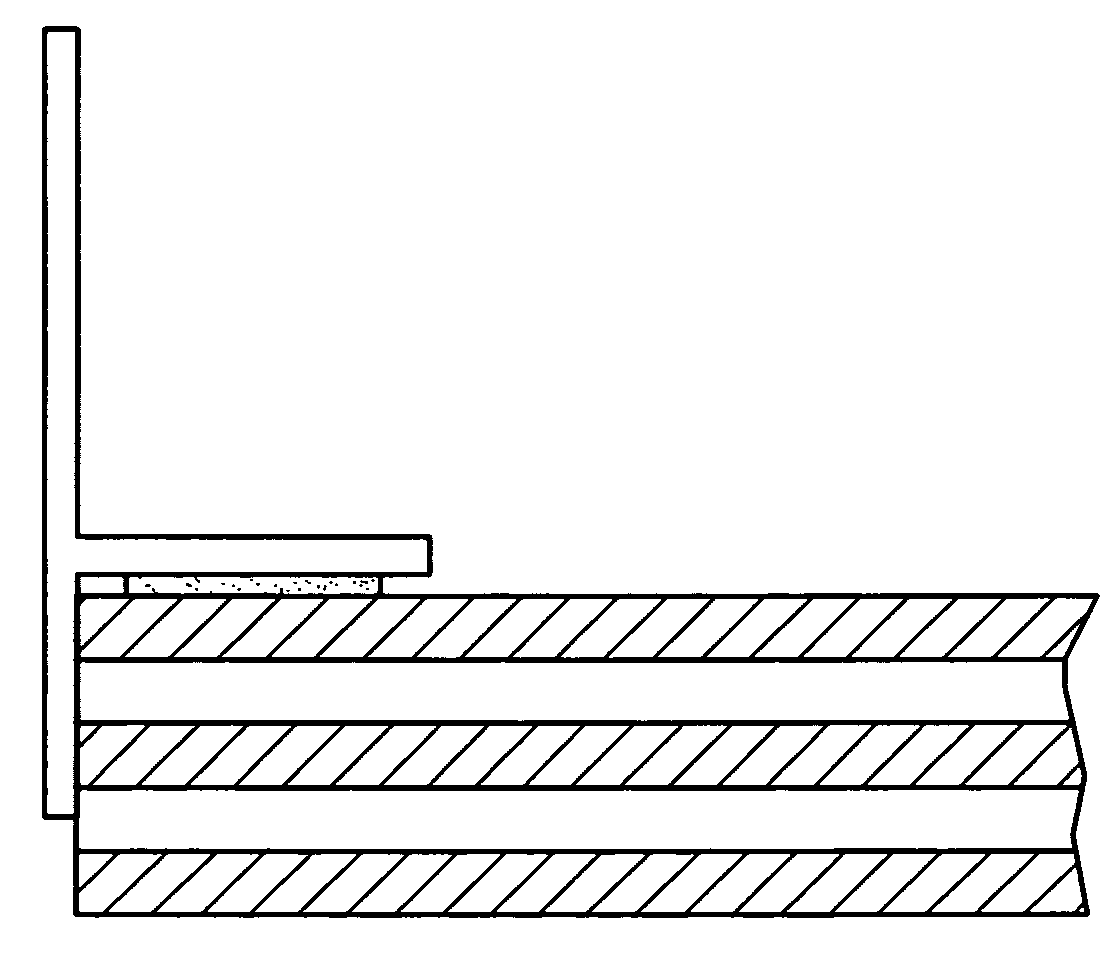

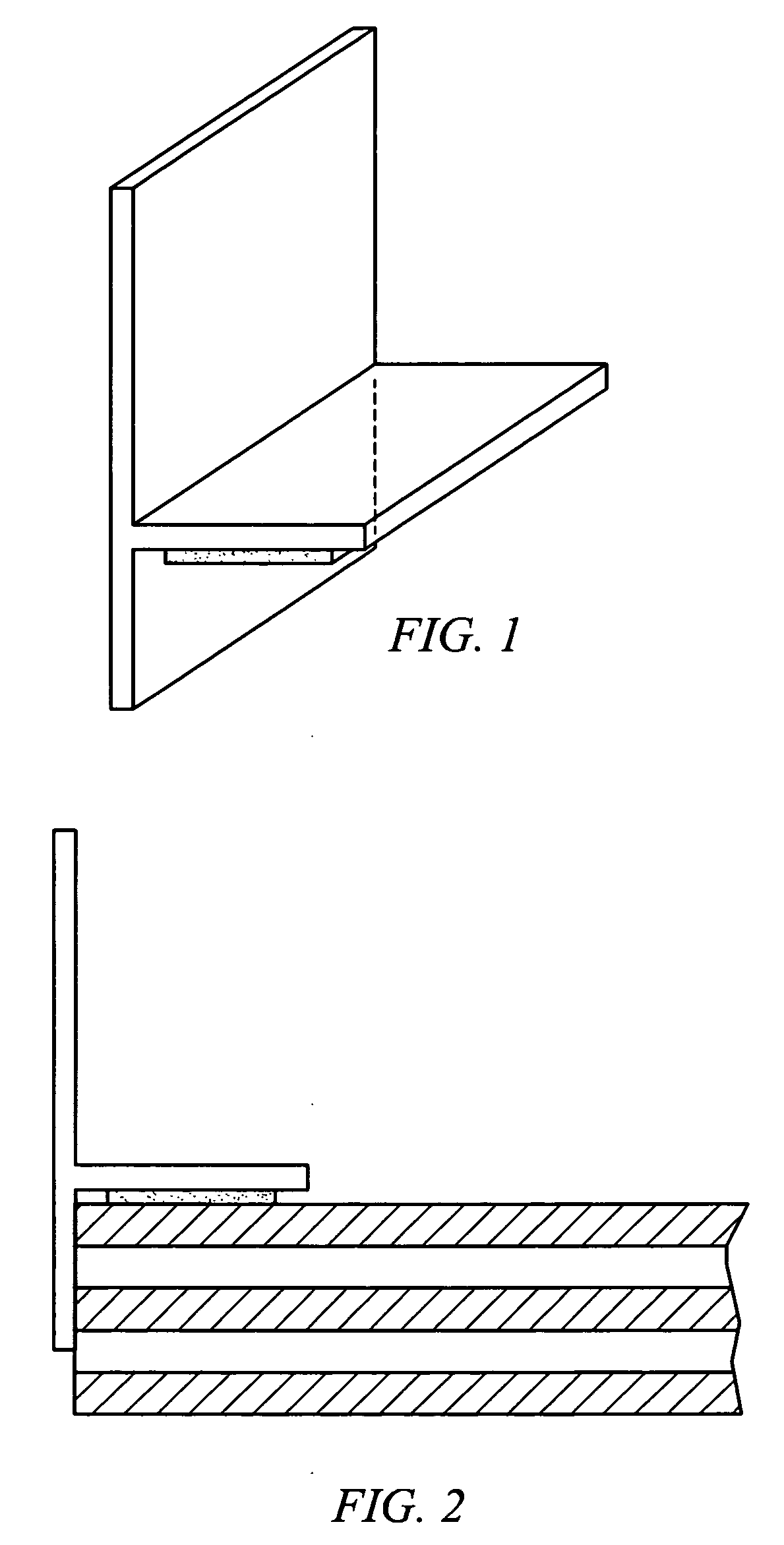

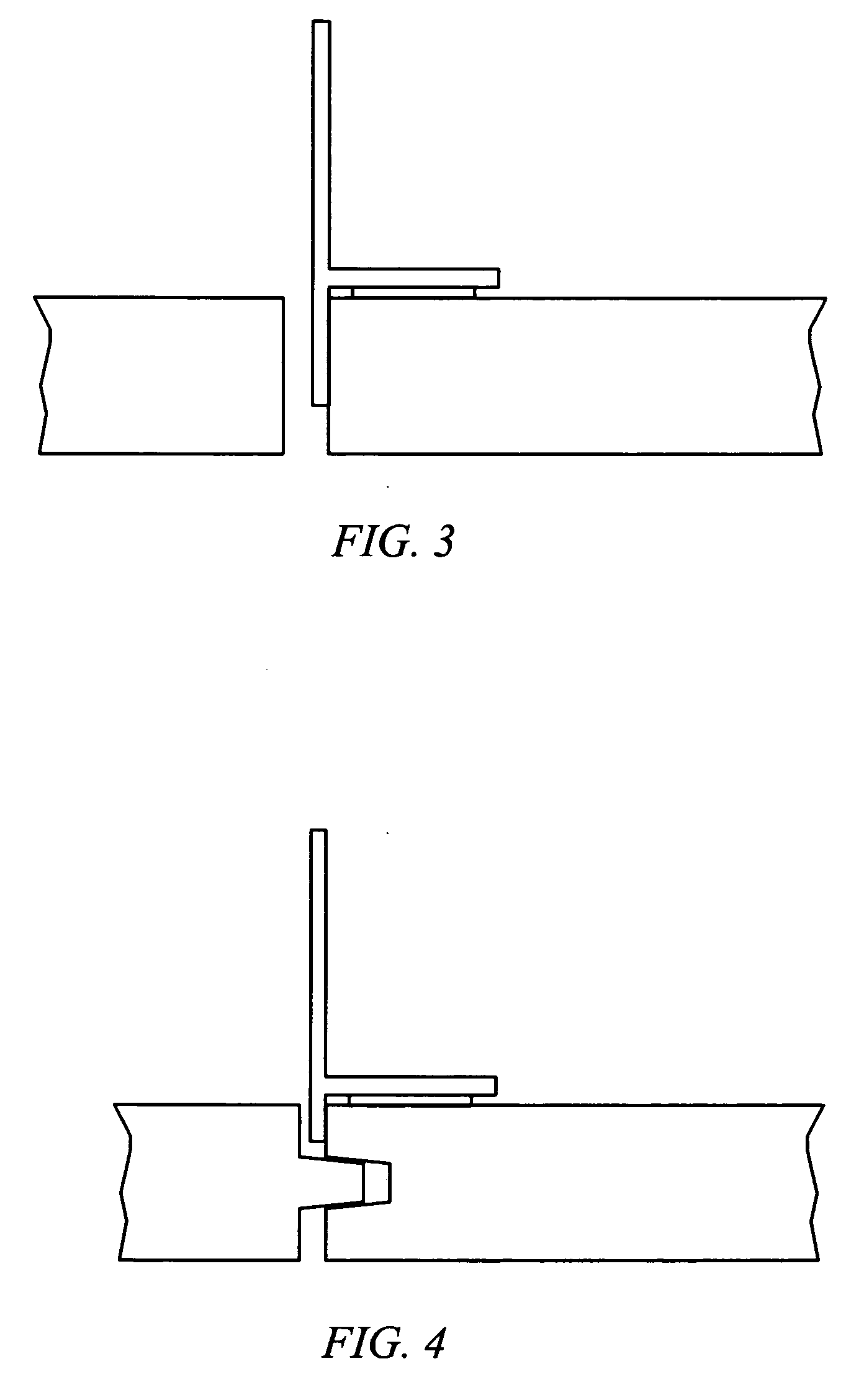

[0023] A spacer device in accordance with the present invention, generally, includes: a generally T shaped spacer body having a top edge, a left bottom edge, a right bottom edge, a left edge, and a right edge, wherein each spacer may be manufactured in various sizes and lengths of the various edges, as well as the relative lengths and sizes of the edges; or a a generally L shaped spacer body having a bottom edge, a right edge, and a left edge, wherein each spacer may be manufactured in various sizes and lengths of the various edges, as well as the relative lengths and sizes of the edges

[0024] A generally L shaped spacer body with a triangular piece connecting the two edges, positioned on top of the leading edges, as shown in FIGS. 7, 8, 9, and 10 for use as a corner spacer.

[0025] A spacer as described with an affixed tab for extraction following use.

[0026] A spacer as described, with self adhesive material on one or more edges, thus allowing simple and secure placement of the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com