Casing configuration for revolver cartridge loader

a cartridge loader and casing technology, applied in the field of casing configuration of revolver cartridge loaders, can solve the problems of difficult to quickly load fingers easily slip away from grasping the cylindrical casing, and inability to grasp the loader in a dark environment, so as to achieve quick loading of cartridges, quick alignment, and rapid release of cartridges into the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

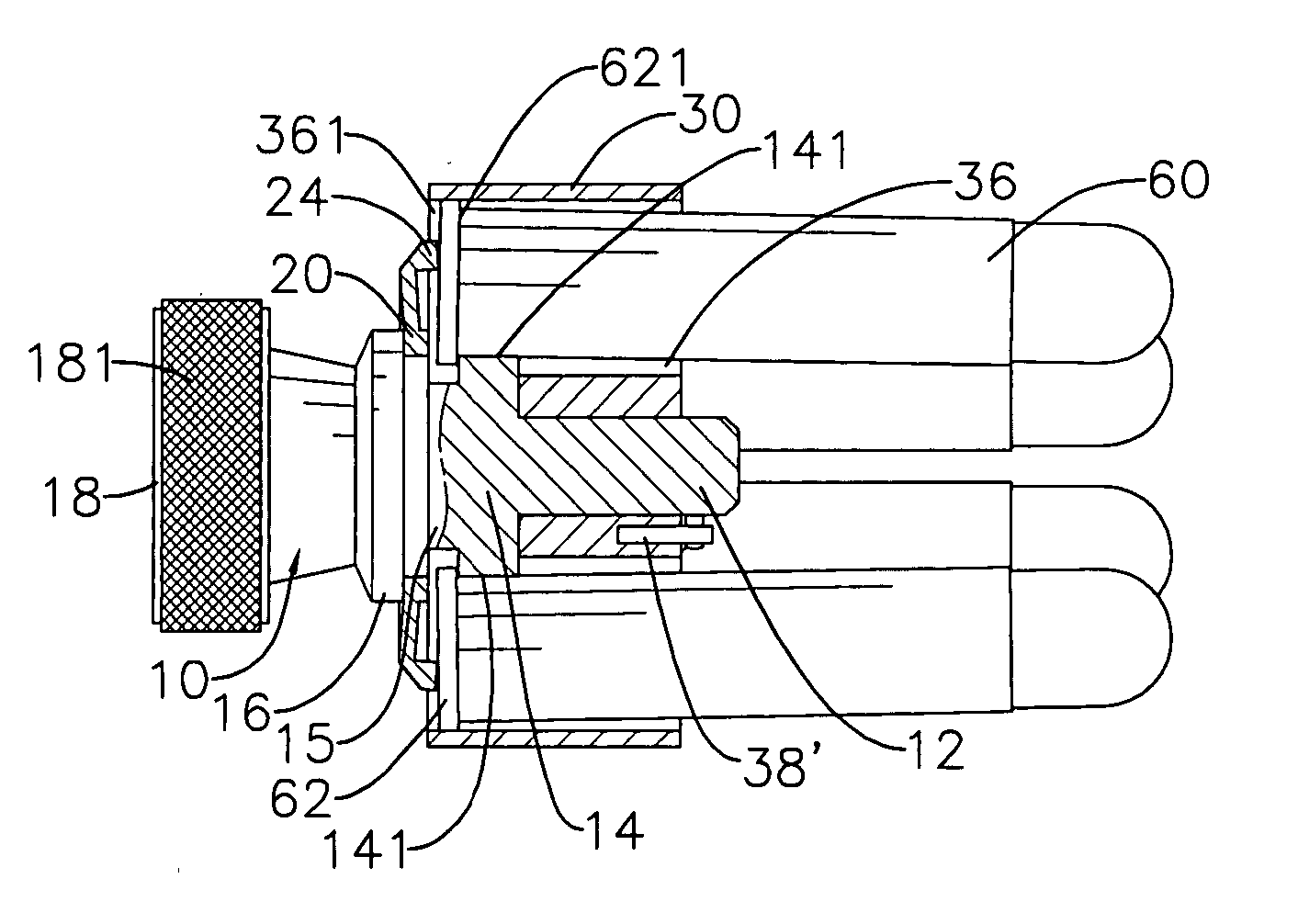

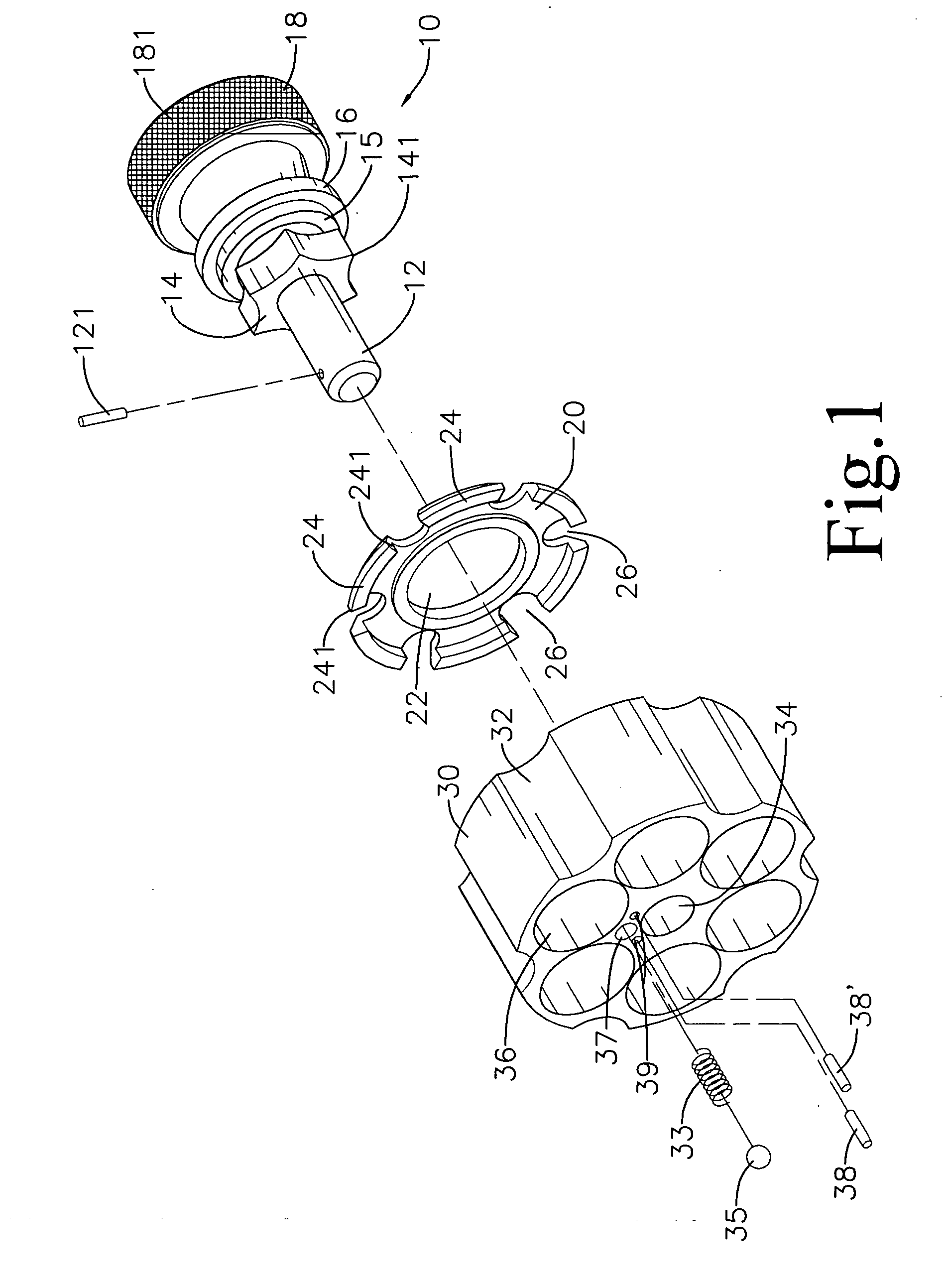

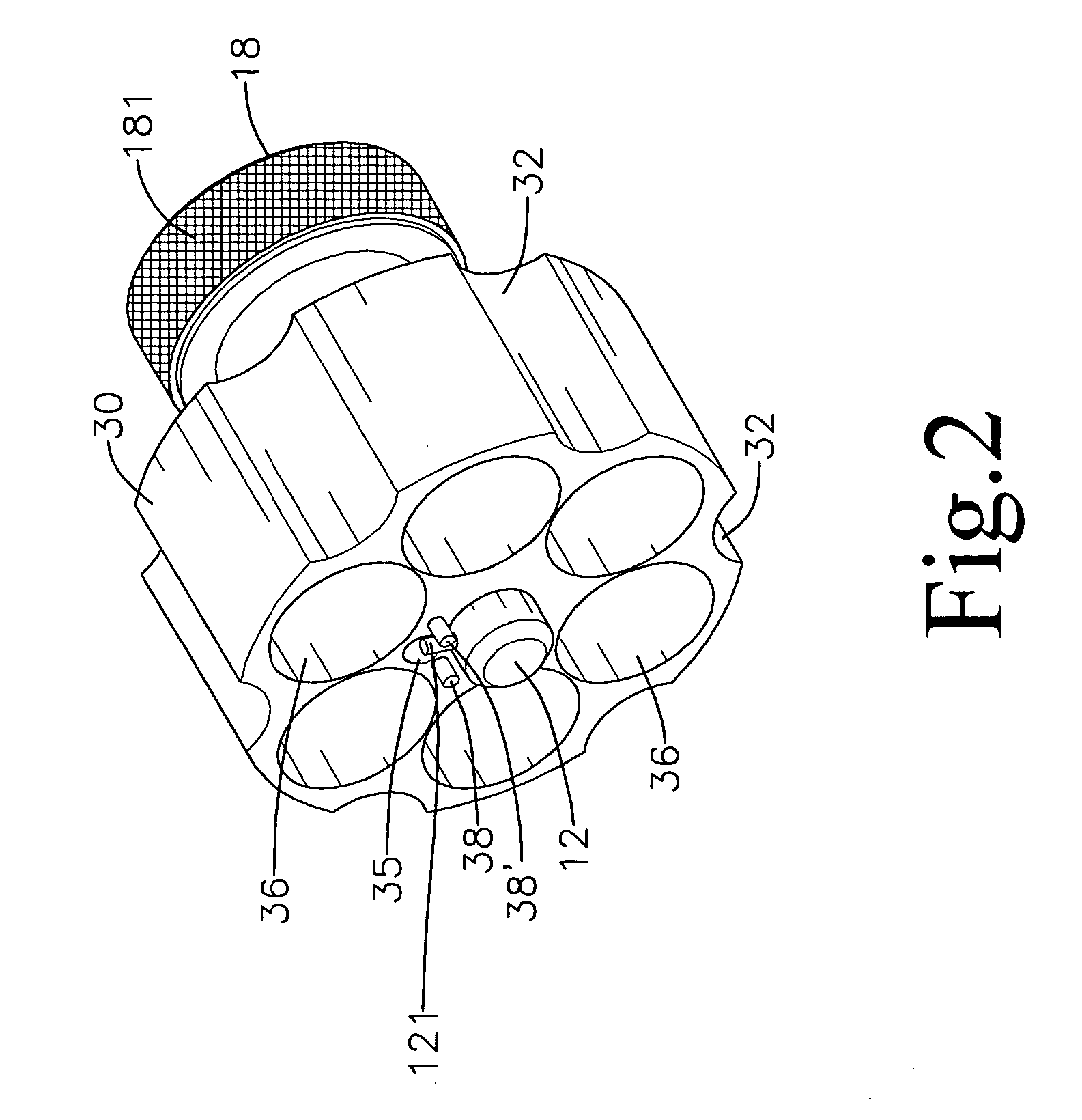

[0027] Referring to FIGS. 3, 6 and 7, which show a plurality of cartridges 60 respectively disposed in cartridge bores 36, at which time pointed protuberants 141 are respectively positioned between adjacent cartridge bores 36. A pin 121 is located between a ball bearing 35 and an inserting pin 38′, and thereby assumes a fixed position state, Fingers are used to rotate a circular ring 18, whereupon a shaft member 12, a pointed gear member 14, a small circular collar 15 and a large circular collar 16 rotate in synchronization. The pin 121 reverse displaces and depresses the ball bearing 35 downward, which thus recedes into a locating hole 37, thereby enabling the pin 121 to pass over the ball bearing 35 and position between the ball bearing 35 and an inserting pin 38, at which time the ball bearing 35 flips upward, and a side portion of the ball bearing 35 presses on the pin 121.

[0028] Referring to FIGS. 4 and 5, which show the pointed protuberants 141 respectively engaging an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com