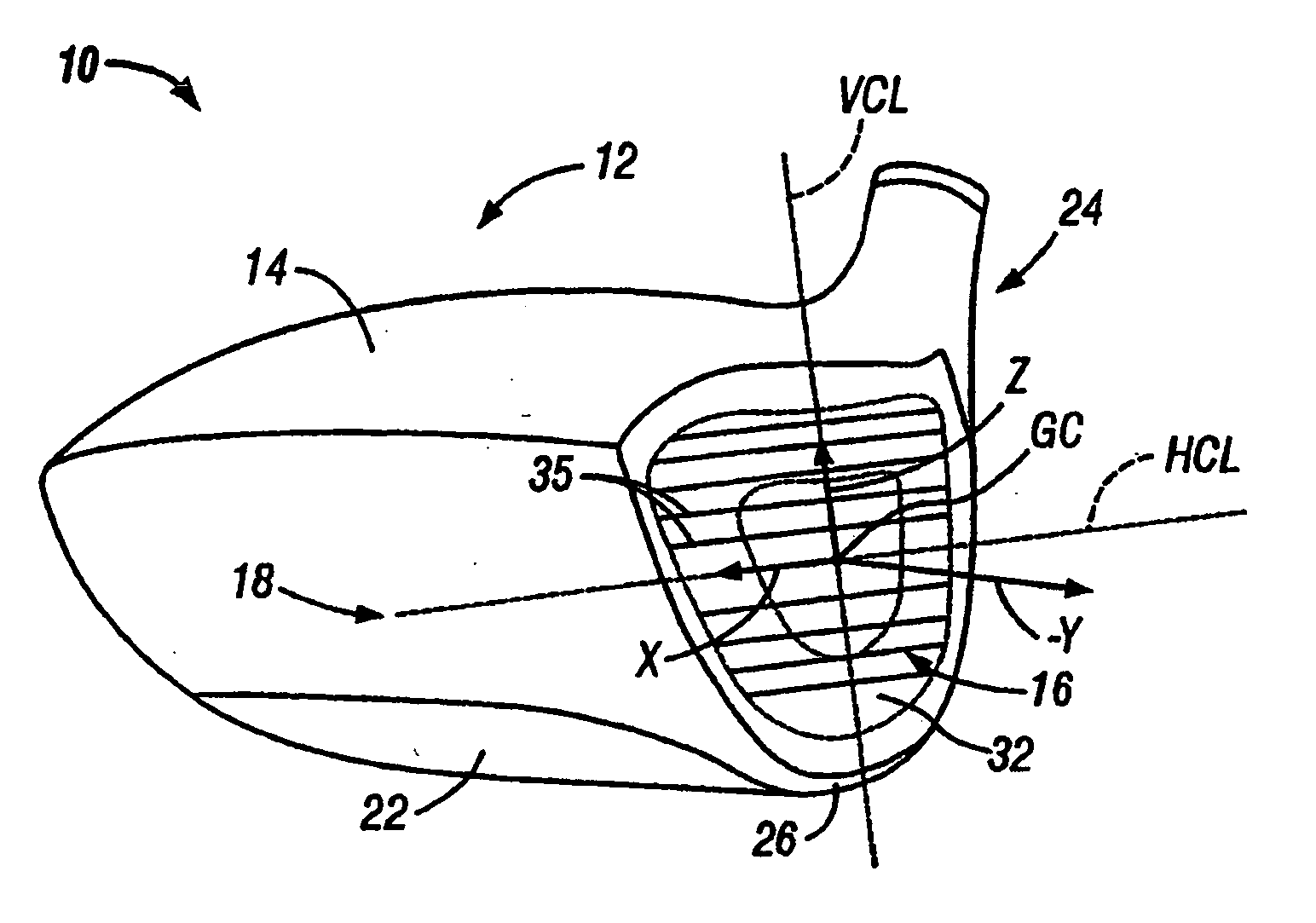

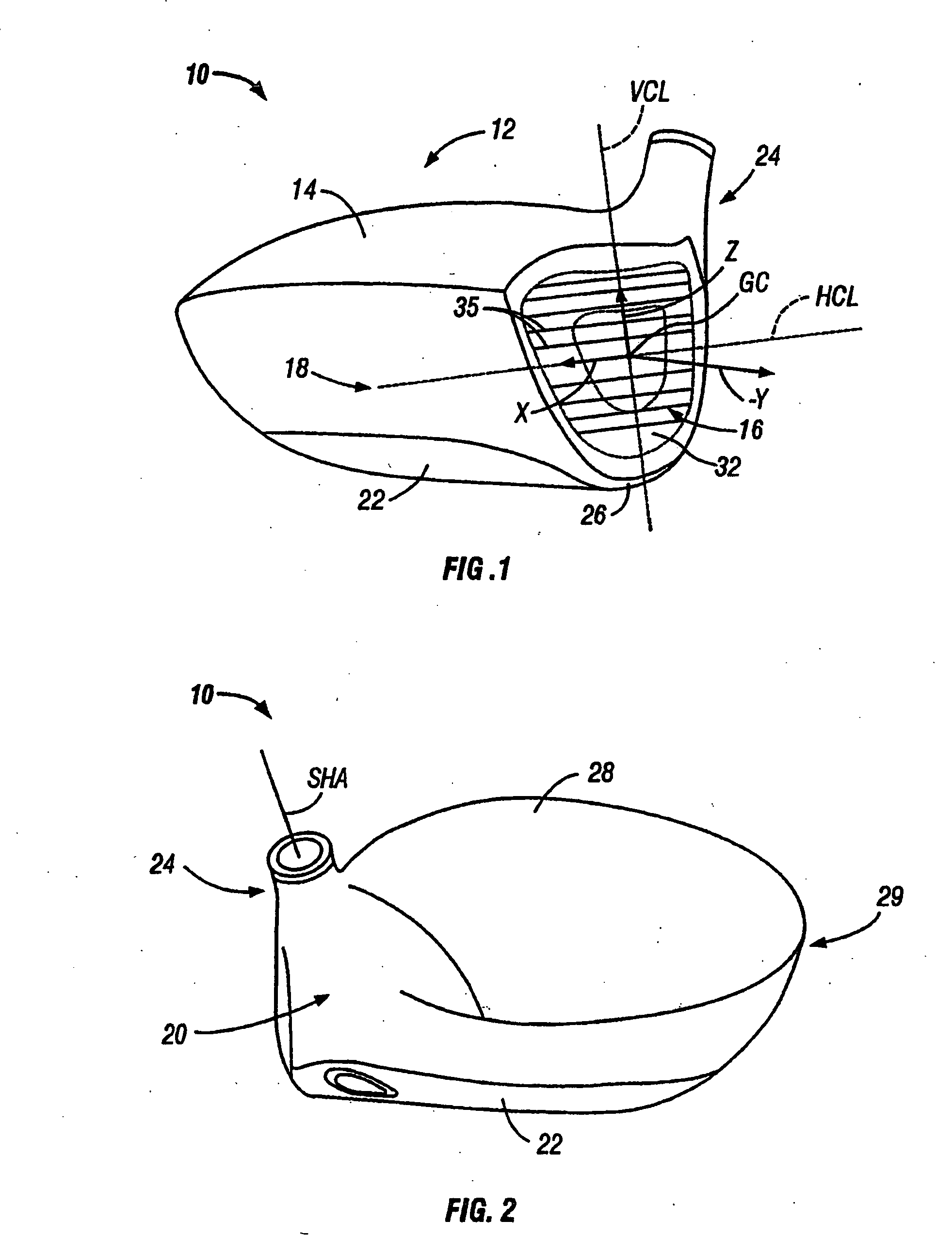

Golf club head with variable flexural stiffness for controlled ball flight and trajectory

a golf club and variable flexural stiffness technology, applied in the field of golf club heads, can solve the problems of high dependence on the accuracy of conventional clubs, environmental effects that are beyond the control of golf equipment manufacturers, etc., and achieve the effect of high ball velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0072] These and other aspects of the present invention may be more fully understood with reference to the following non-limiting examples, which are merely illustrative of embodiments of the present invention golf club head, and are not to be construed as limiting the invention, the scope of which is defined by the appended claims.

TABLE 1FLEXURAL STIFFNESS INFORMATIONComparativeComparativeComparativeInventiveParameterExample 1Example 2Example 3ExampleThickness of Center Zone0.1150.1300.0950.150(inches)Thickness of First0.1150.1000.0980.075Intermediate Zone (inches)Thickness of Second0.1150.0800.1000.075Intermediate Zone (inches)Thickness of Perimeter0.1150.1500.1200.120Portion (inches)E of All Portions (psi)1.65E+071.65E+071.65E+071.65E+07FS of Center Portion25094362511414755688(lb-in)FS of First Intermediate2509416500155306961zone (lb-in)FS of Second Intermediate250948448165006961Zone (lb-in)FS of Perimeter Zone25094556882851228512(lb-in)FS1 / FS21.02.20.98.0FS3 / FS21.03.41.84.1

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com