Handheld vacuum with accelerated cyclonic flow and air freshener

a technology of cyclonic flow and vacuum, which is applied in the field of vacuums, can solve problems such as affecting its effectiveness, and achieve the effects of preventing the cyclonic flow from accelerating, and improving the efficiency of the centrifugal chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

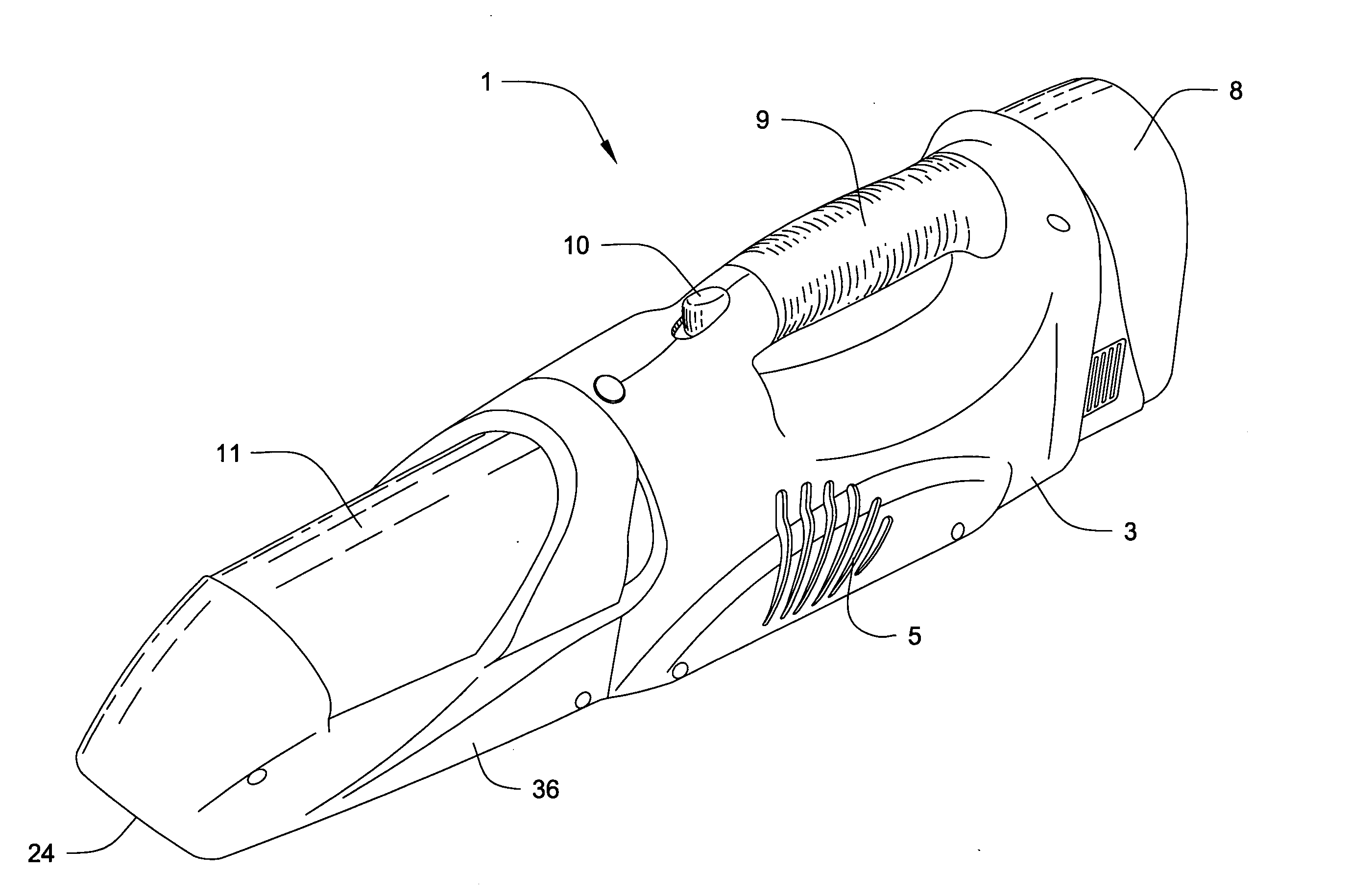

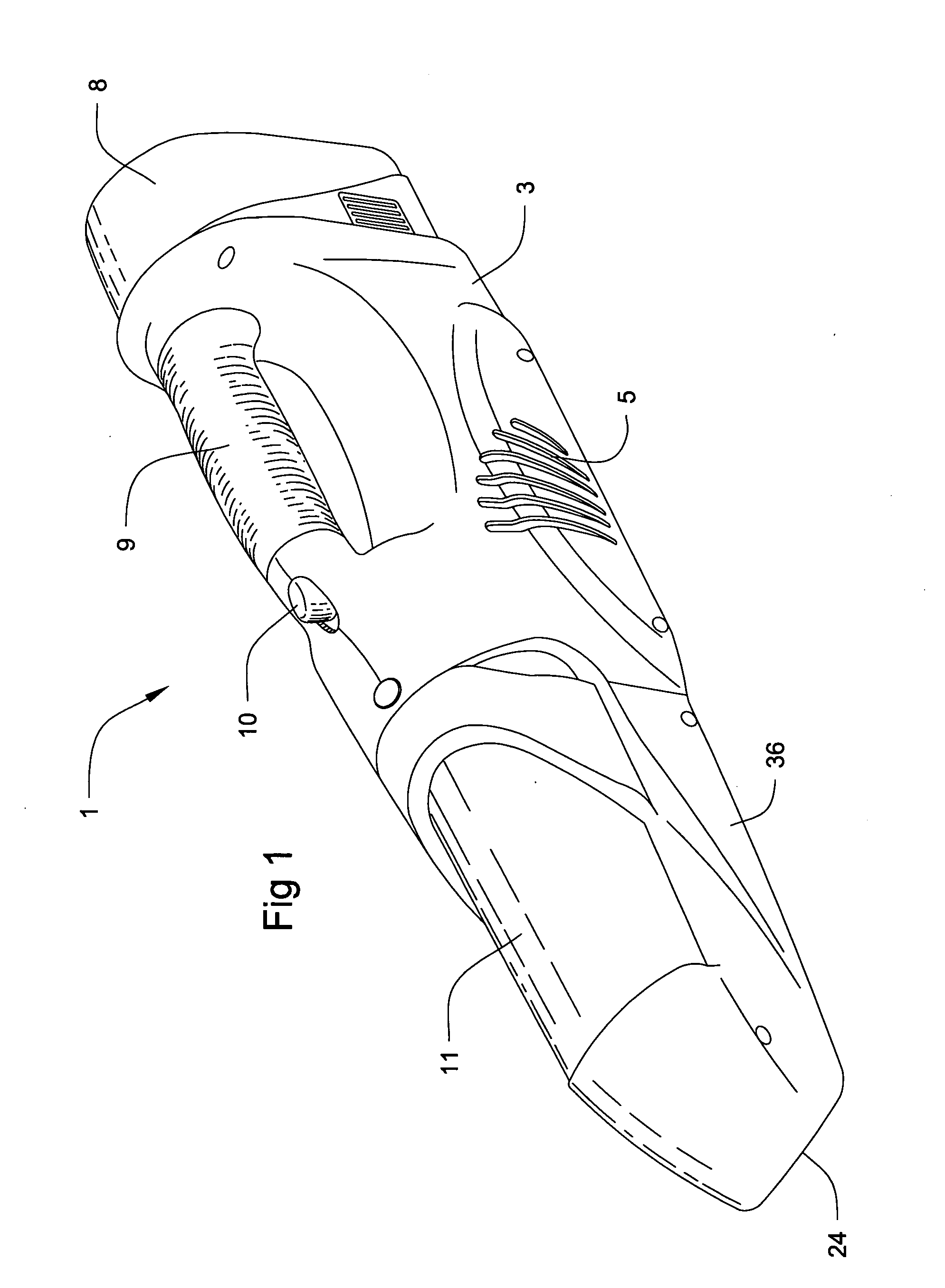

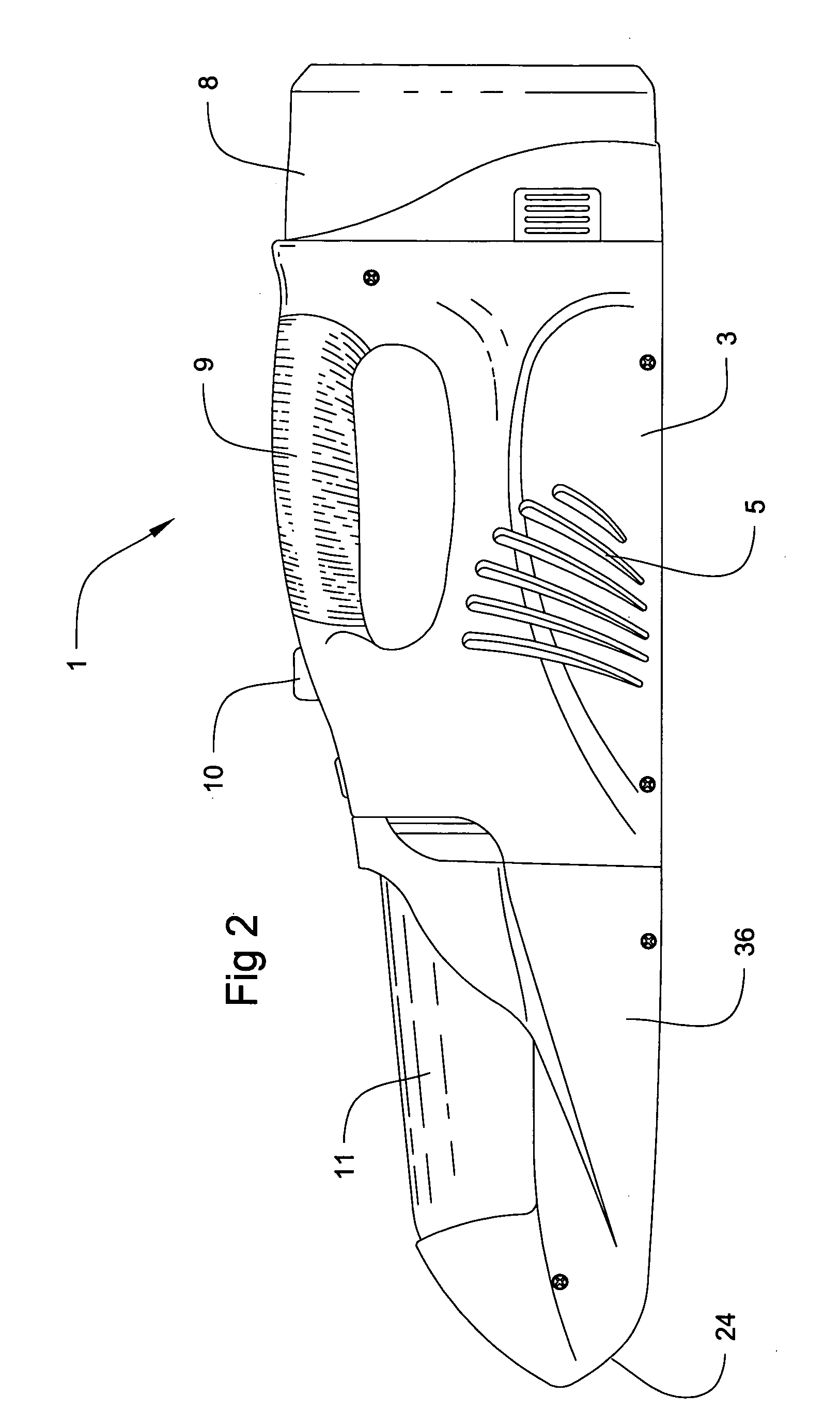

[0026] The invention is primarily directed toward hand held vacuums 1, that is vacuums 1 of less than about three feet in length and less than about one foot in either width or height. In the preferred embodiment, vacuum 1 includes a suction chamber 2. Suction chamber 2 comprises a suction housing 3 which will preferably include at least one intake aperture 4 and at least one outflow vent 5. Suction housing 3 will preferably include at least one motor 6. Motor 6 is configured to drive at least one fan 7 when motor 6 is activated. Fan 7 is positioned and configured to draw air into intake aperture 4, through suction housing 3 and out vent 5 when fan 7 is rotated. A power source 8 is provided in or on suction housing 3. Power source 8 may be a battery or batteries, an electrical line leading to a wall or automotive outlet, or any other conventional source of power suitable for operation of motor 6. Suction housing 3 will also preferably include a handle 9 and a switch 10 for activatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com