Power lift and tilt modules

a technology of power lift and module, which is applied in the direction of wheelchair/patient conveyance, movable seat, chair, etc., can solve the problems of premature wear of the actuator, high load on the actuator,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

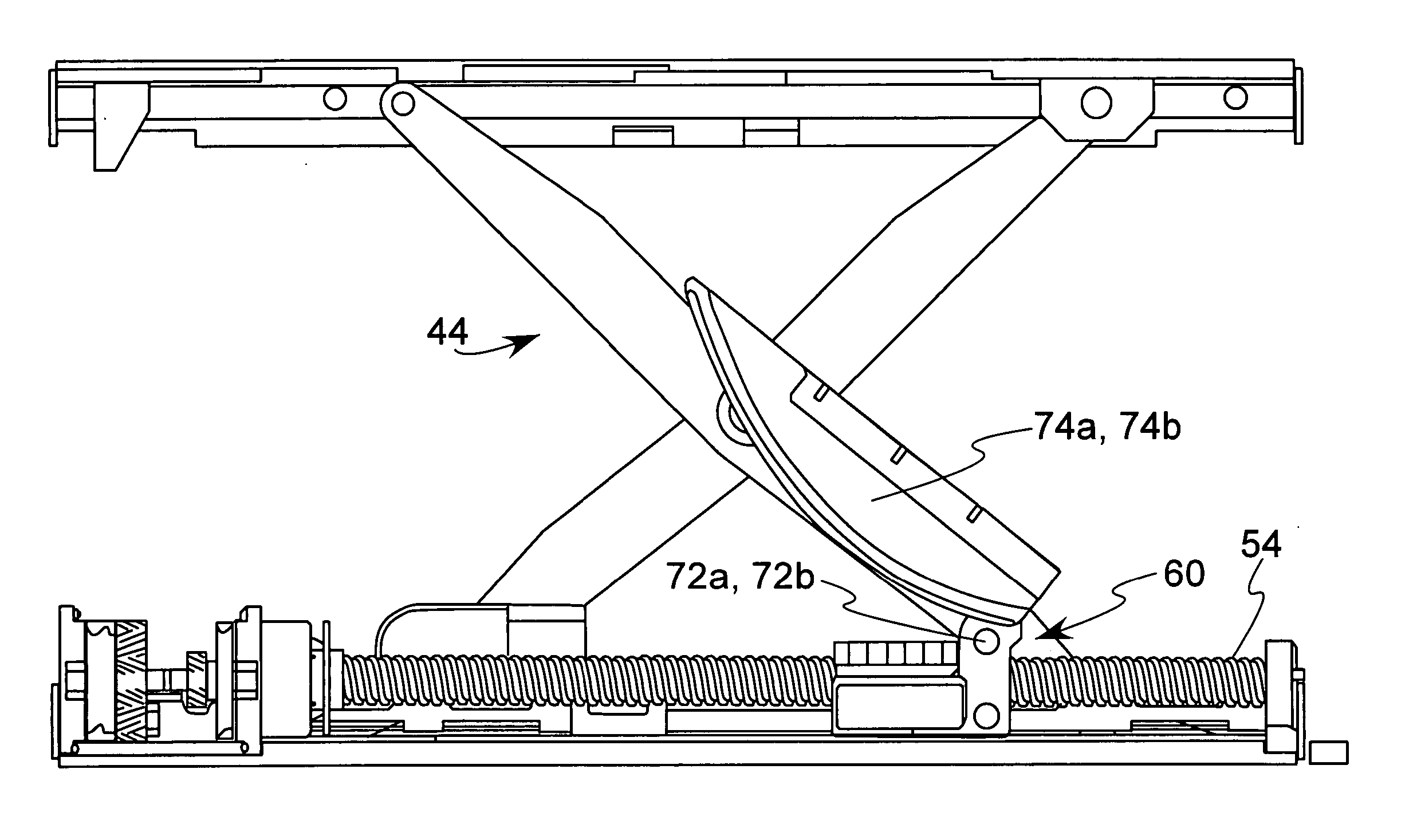

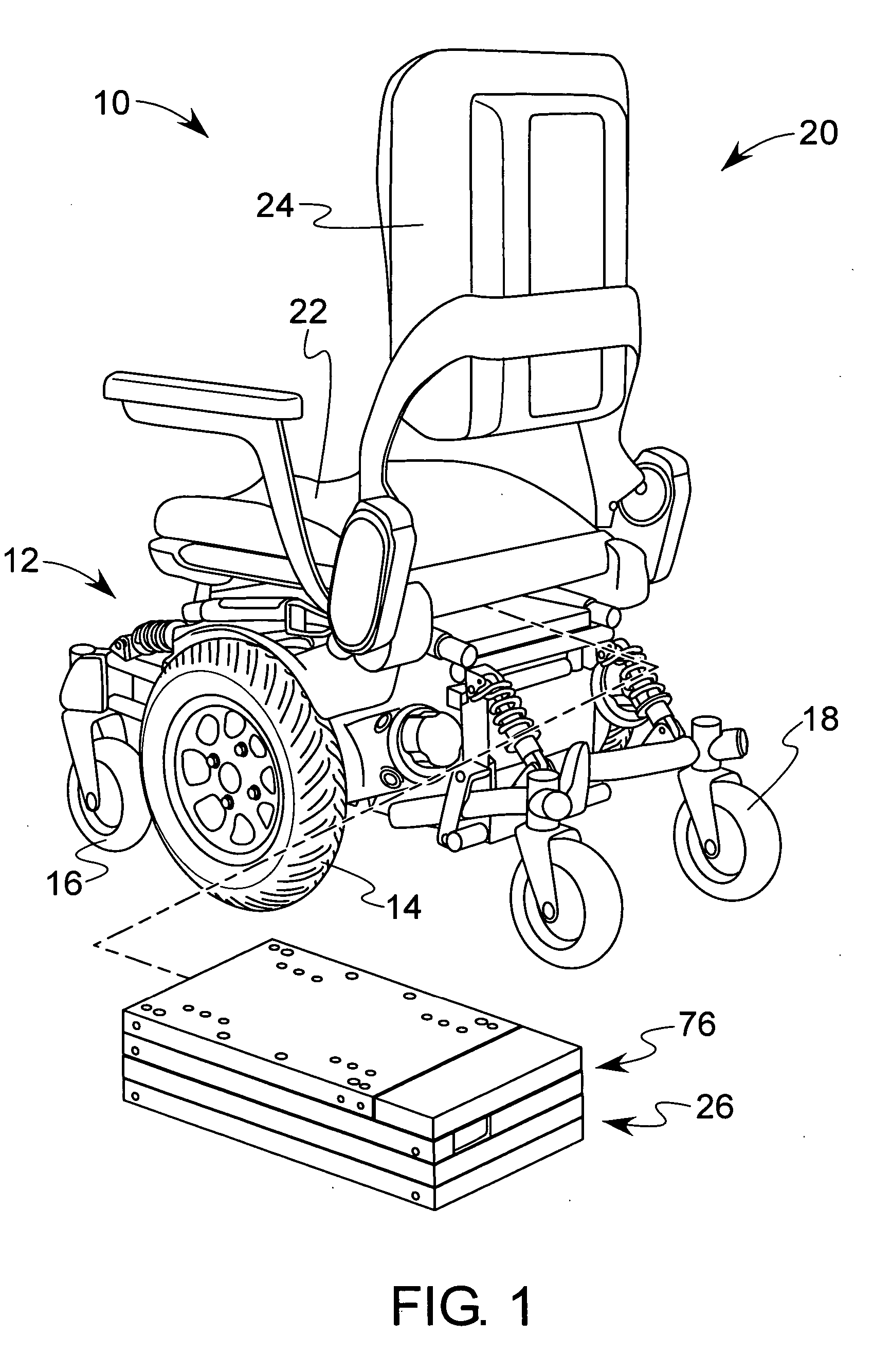

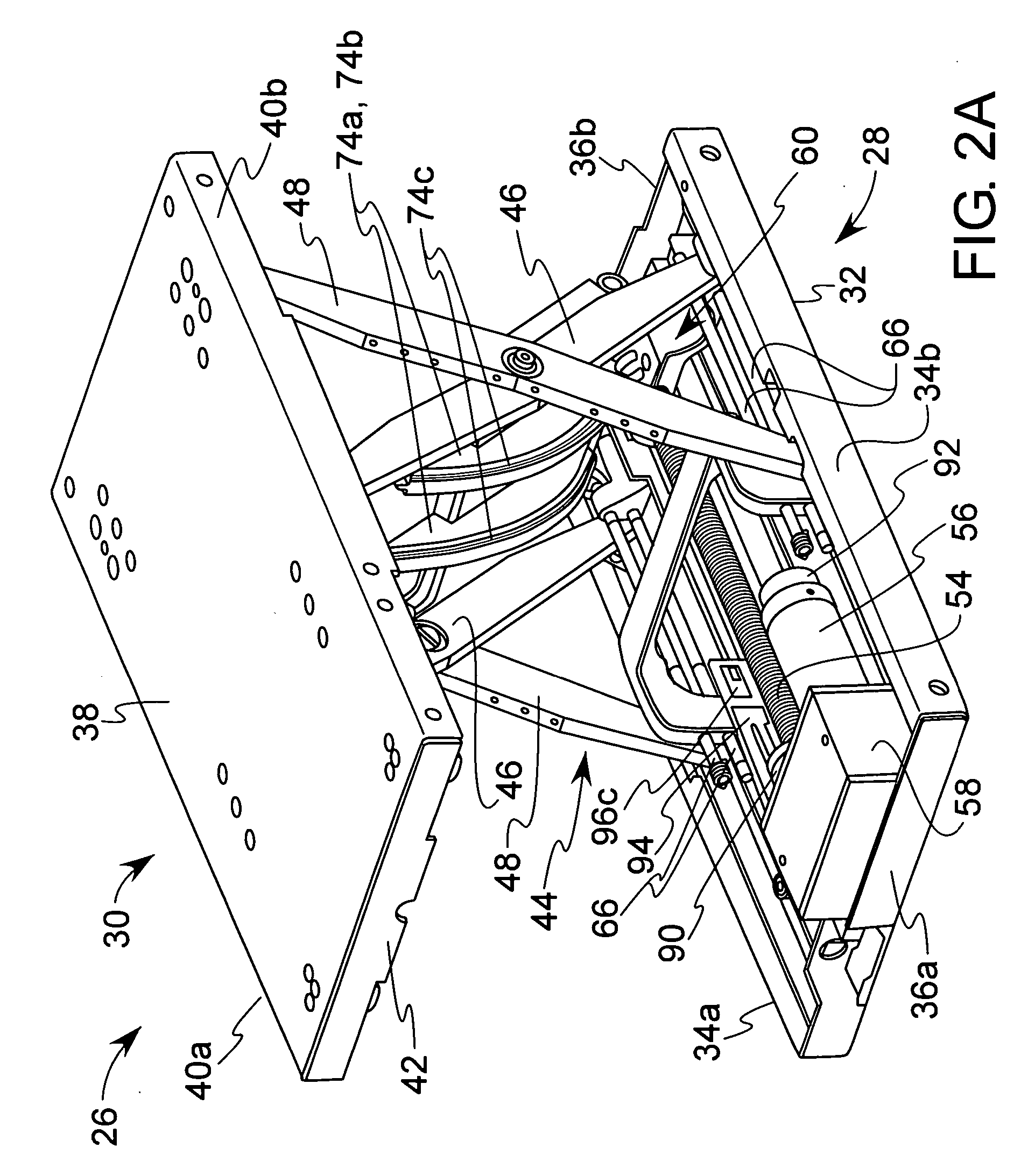

[0019] Referring now to the drawings, there is illustrated in FIG. 1 a wheelchair 10 and a modular actuator according to the present invention. The wheelchair 10 is a power wheelchair and more particularly, a mid-wheel drive wheelchair, although the invention can be practiced with other suitable drive configurations, such as front and rear wheel drive configurations. The wheelchair 10 comprises a base 12, which includes a frame supported on a supporting surface by a plurality of wheels, such as drive wheels 14, front wheels 16, and rear wheels 18, as shown in the drawing. The drive wheels 14 can be powered by any suitable power source and can be controlled by any suitable input device, including but not limited to a joystick (not shown). A seat assembly 20 is supported by the base 12. The seat assembly 20 comprises a seat 22 and a seat back 24, which may articulate (i.e., recline) relative to the seat 22. According to the present invention, the seat assembly 20 is adapted to be supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com