Device for longitudinal cutting of a continuous web material, such as corrugated cardboard

a technology of web material and longitudinal cutting, which is applied in the direction of metal working equipment, shearing machines, shearing apparatus, etc., can solve the problems of extreme precision in the adjustment of the distance between the cutting edges of the blades and the edge of the counter-blade, rapid wear of the plastic in the channel, and the need to reduce the risk of damage to the material. , to achieve the effect of simplifying the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

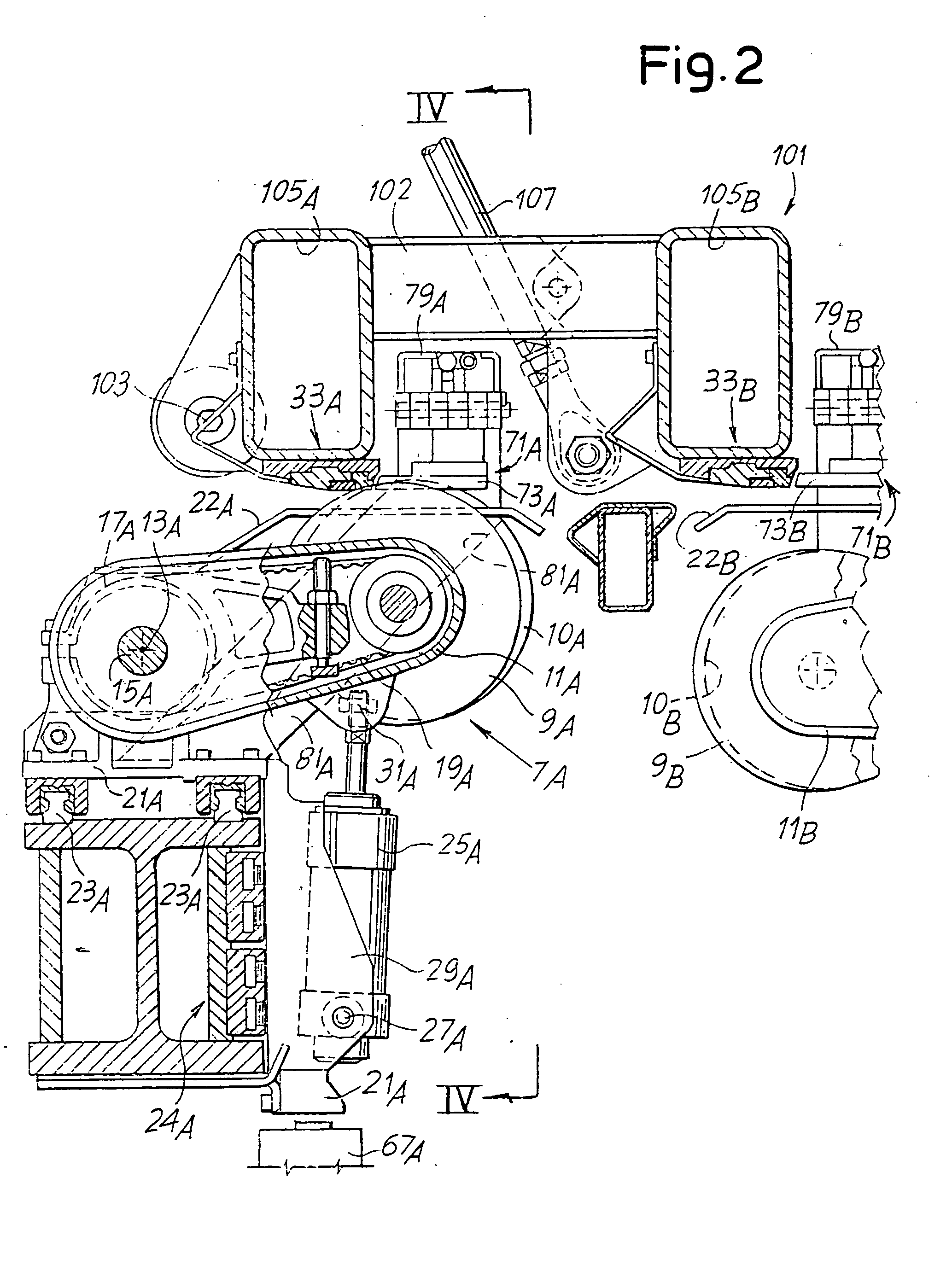

[0030] The accompanying drawing shows an application of the invention to a double slitter-scorer machine, but it must be understood that the principles on which the invention is based can also be applied to machines of a different type, such as machines with a single cutting unit instead of two cutting units which operate alternately, or to machines with no scoring station, or even in more complex machines with a greater number of scoring and slitting stations.

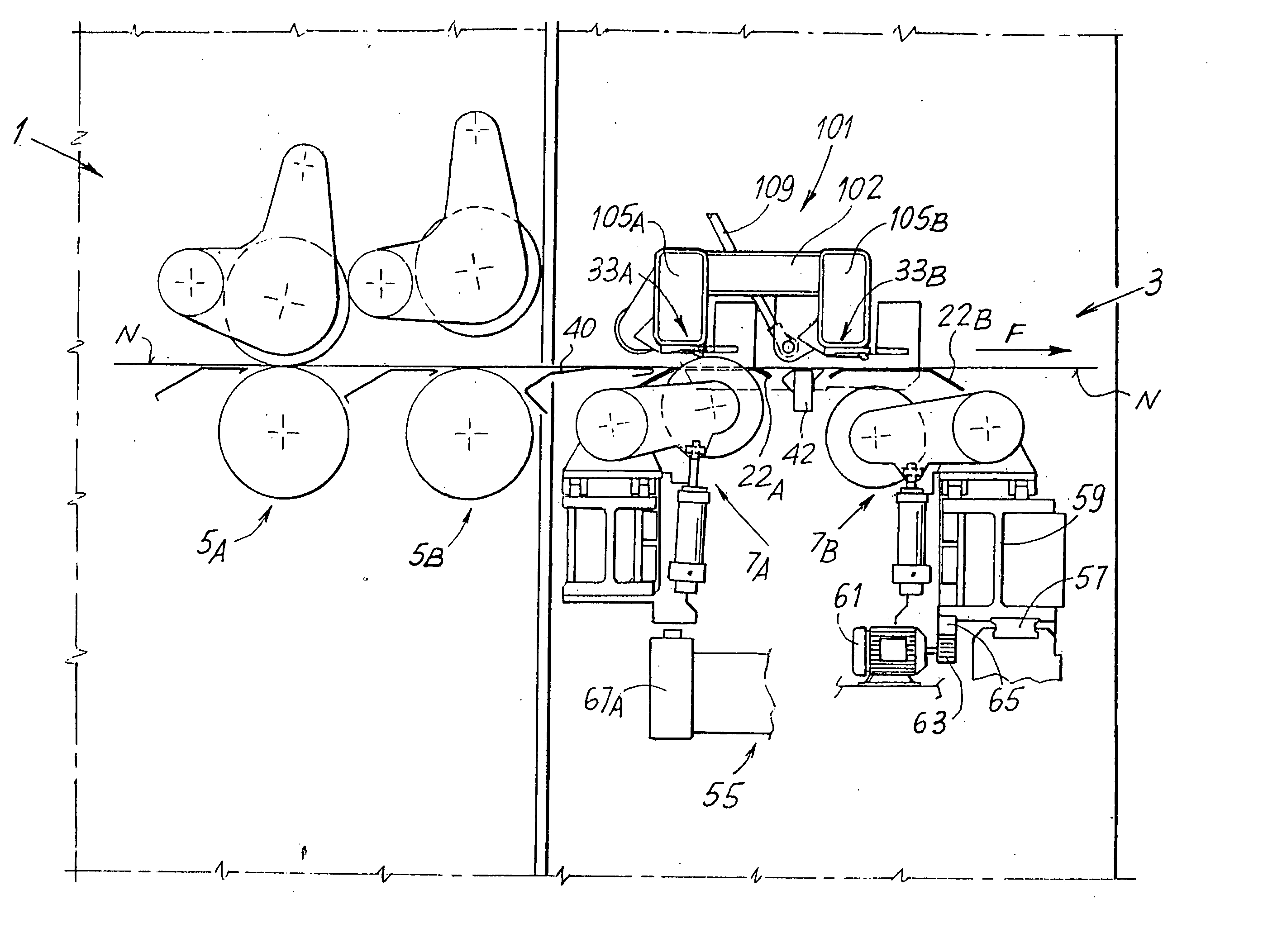

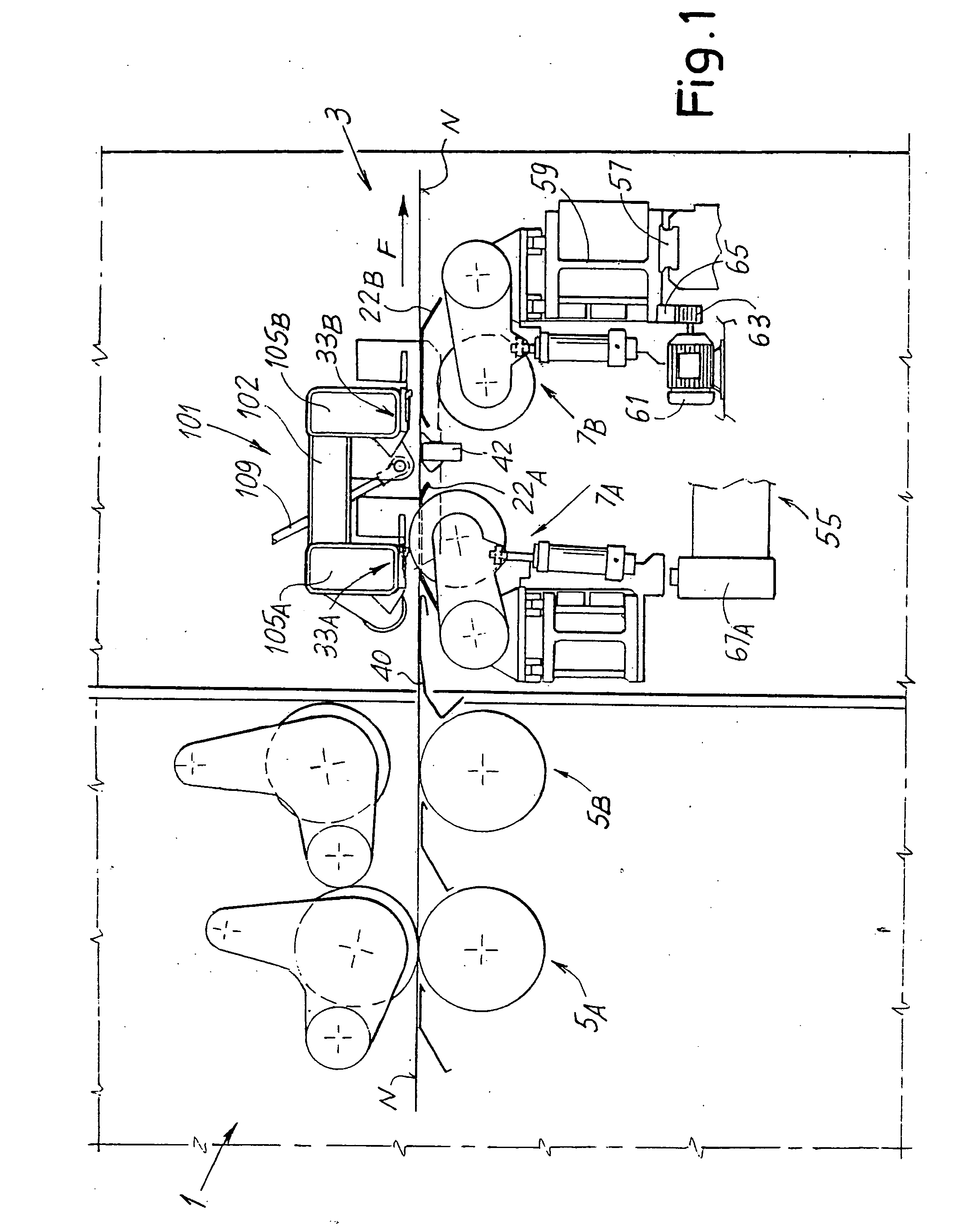

[0031]FIG. 1 schematically shows a lateral view of the slitter-scorer machine, in which the number 1 schematically indicates the scoring section and the number 3 the slitting section. The scoring section comprises a first series of scoring tools 5A and a second series of scoring tools 5B. In the layout shown in FIG. 1 the scoring tools 5A are in the operating condition and act on the web material N, typically a corrugated cardboard web. The scoring tools 5B are in the inoperative position, that is, they do not act on the web ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com