Exhaust flap means

a technology of exhaust flap and means, which is applied in the direction of exhaust treatment, valve details, valve housings, etc., can solve the problems of shaft jamming in operation, damage to bearing means, and inexact coaxial passage openings opposite each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

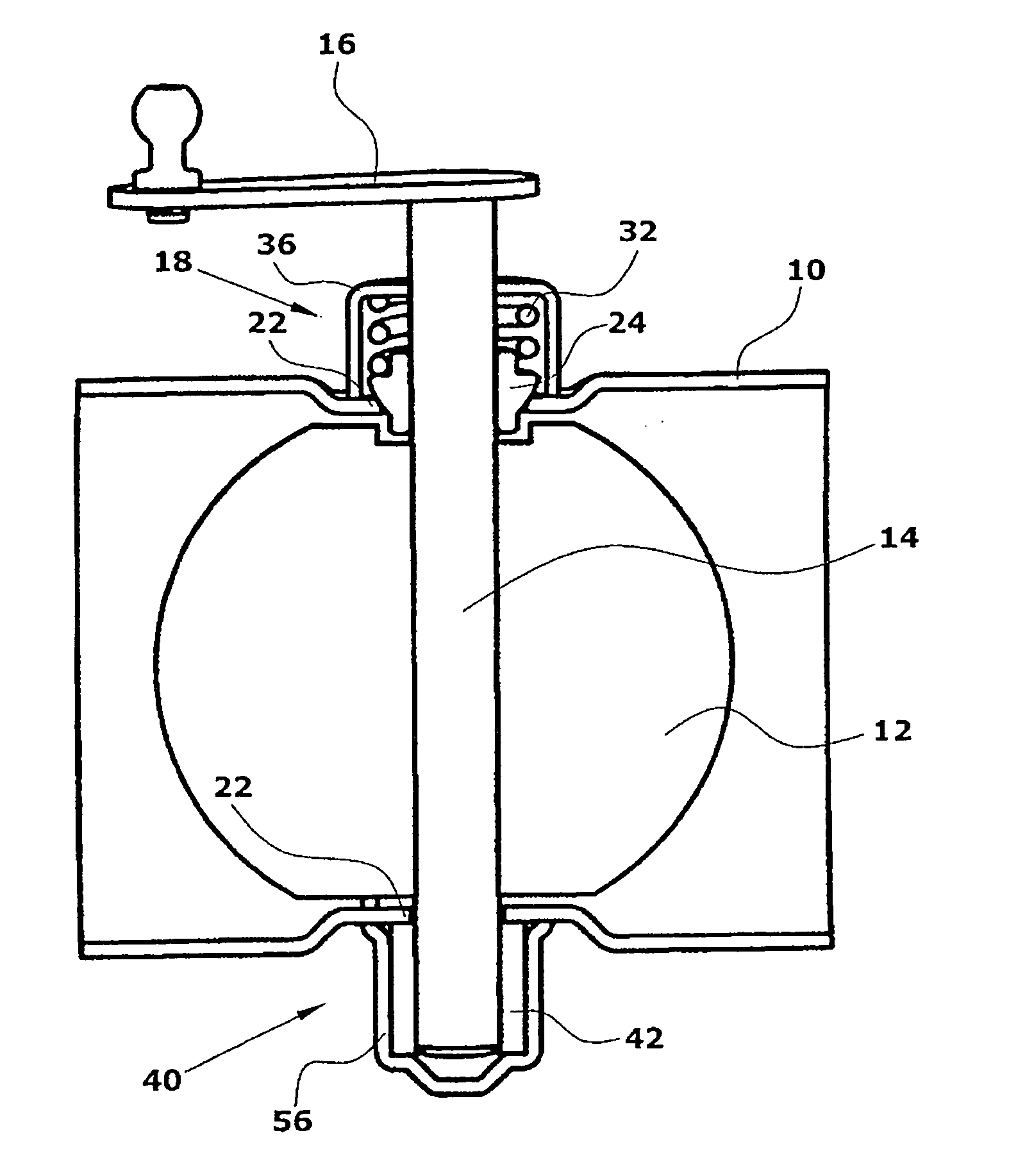

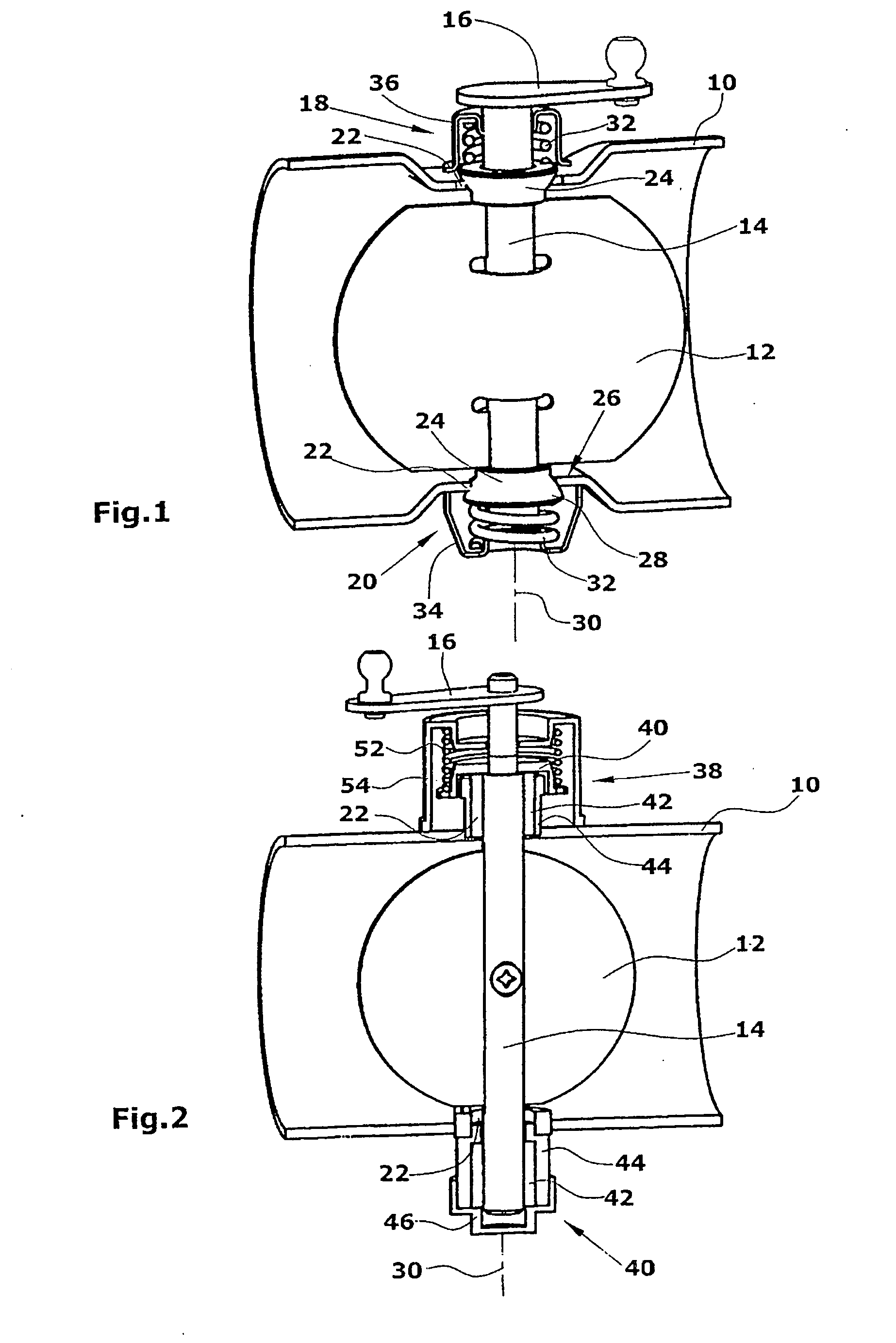

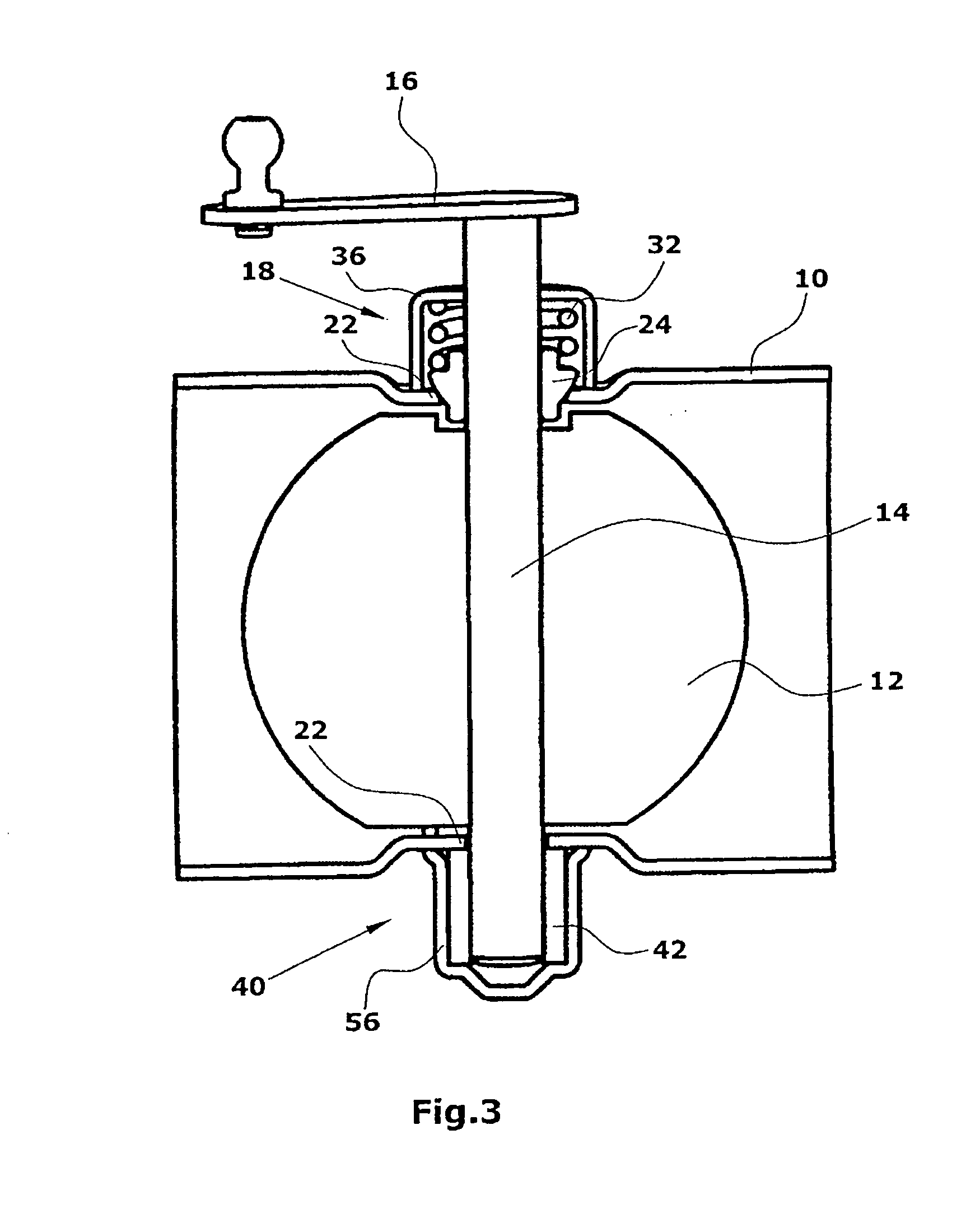

[0021] The exhaust flap means comprises a housing 10 which is substantially tubular and can be inserted into an exhaust gas train. Likewise, the housing 10 can be part of an exhaust pipe. In the housing 10, an exhaust flap 12 is arranged which is connected to a flap shaft 14. At one end, the flap shaft is connected with a lever mechanism 16 which, in turn, is connected with a non-illustrated setting means in an electric motor via a rod assembly or the like. By actuating the setting means, the exhaust flap 12 can be pivoted from the illustrated open position into the closed position that is rotated by 90° at maximum. It goes without saying that intermediate positions are possible as well.

[0022] The flap shaft 14 is supported in two bearing means 18,20 opposite each other. To this end, the housing 10 comprises two passage openings 22 opposite each other which should be arranged coaxially to each other, if possible. Since a coaxiality of the two passage openings 22 is not always given...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com