Projection display systems for light valves

a technology of projection display and light valve, which is applied in the direction of picture reproducers, picture reproducers using projection devices, instruments, etc., can solve the problems of large size, complicated prefiltering system, and large complexity of projection system for reflective liquid crystal display (lcds), so as to reduce the overall size and complexity of the projection display system, reduce the size of the distribution and recombination system, and reduce the overall complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

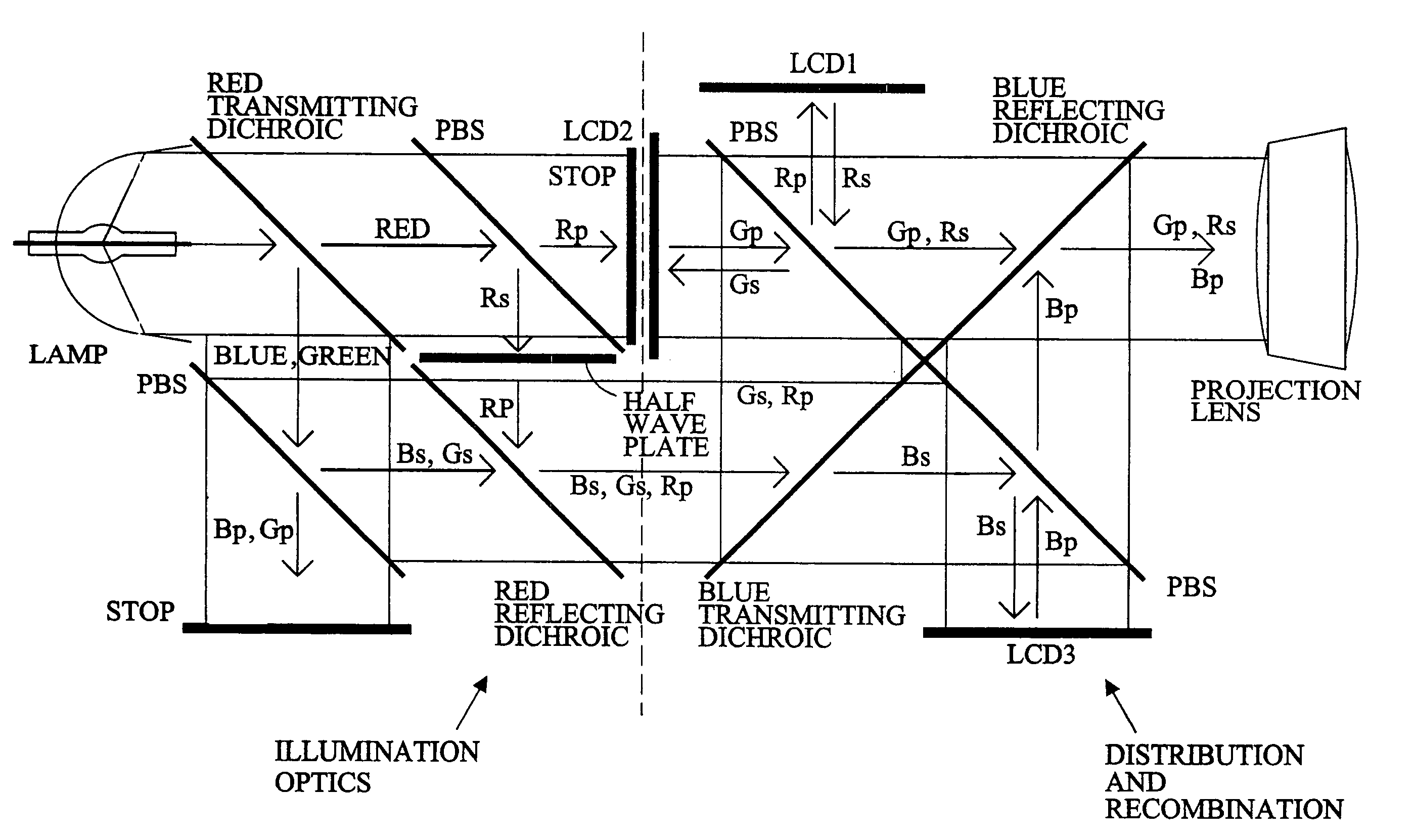

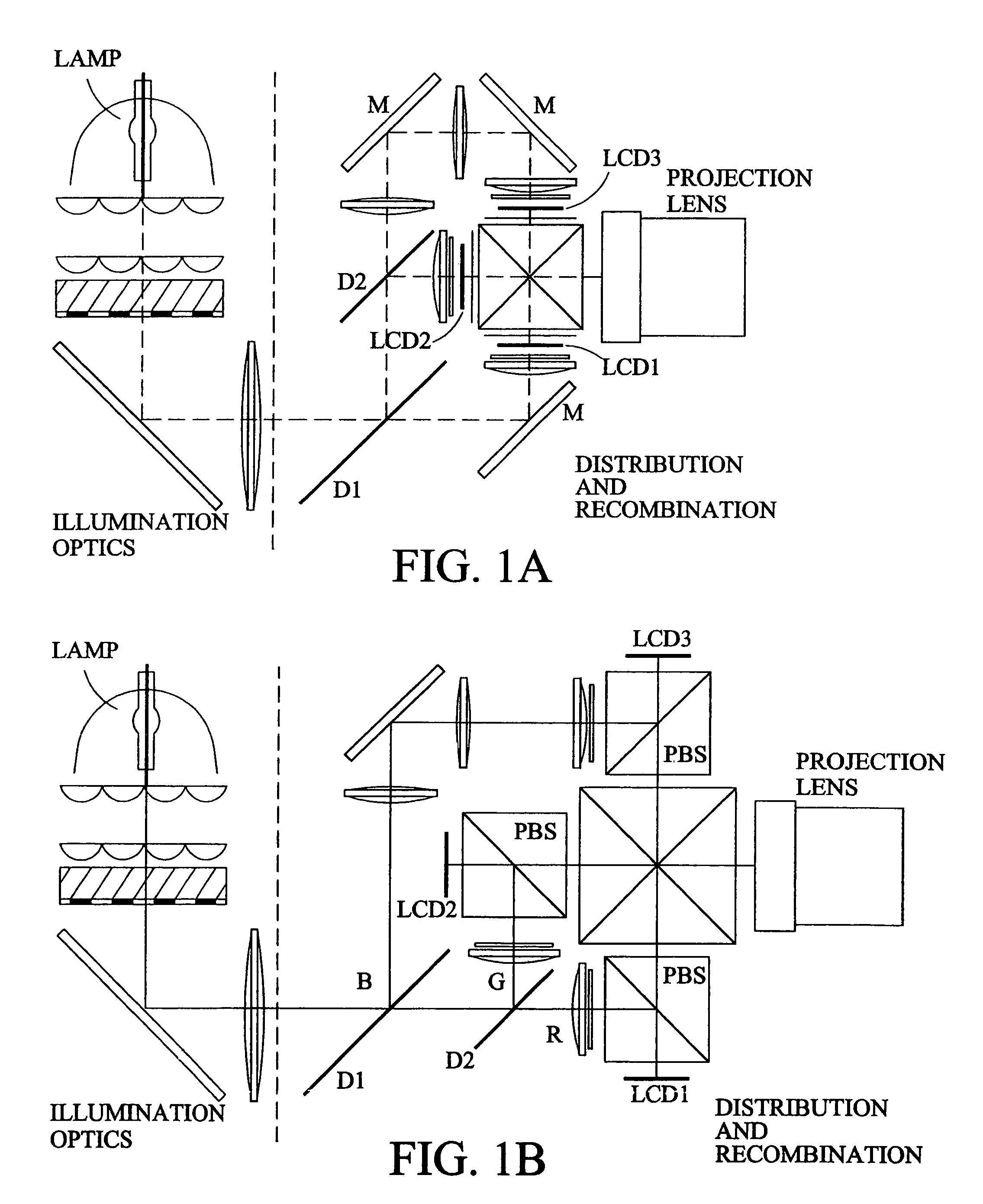

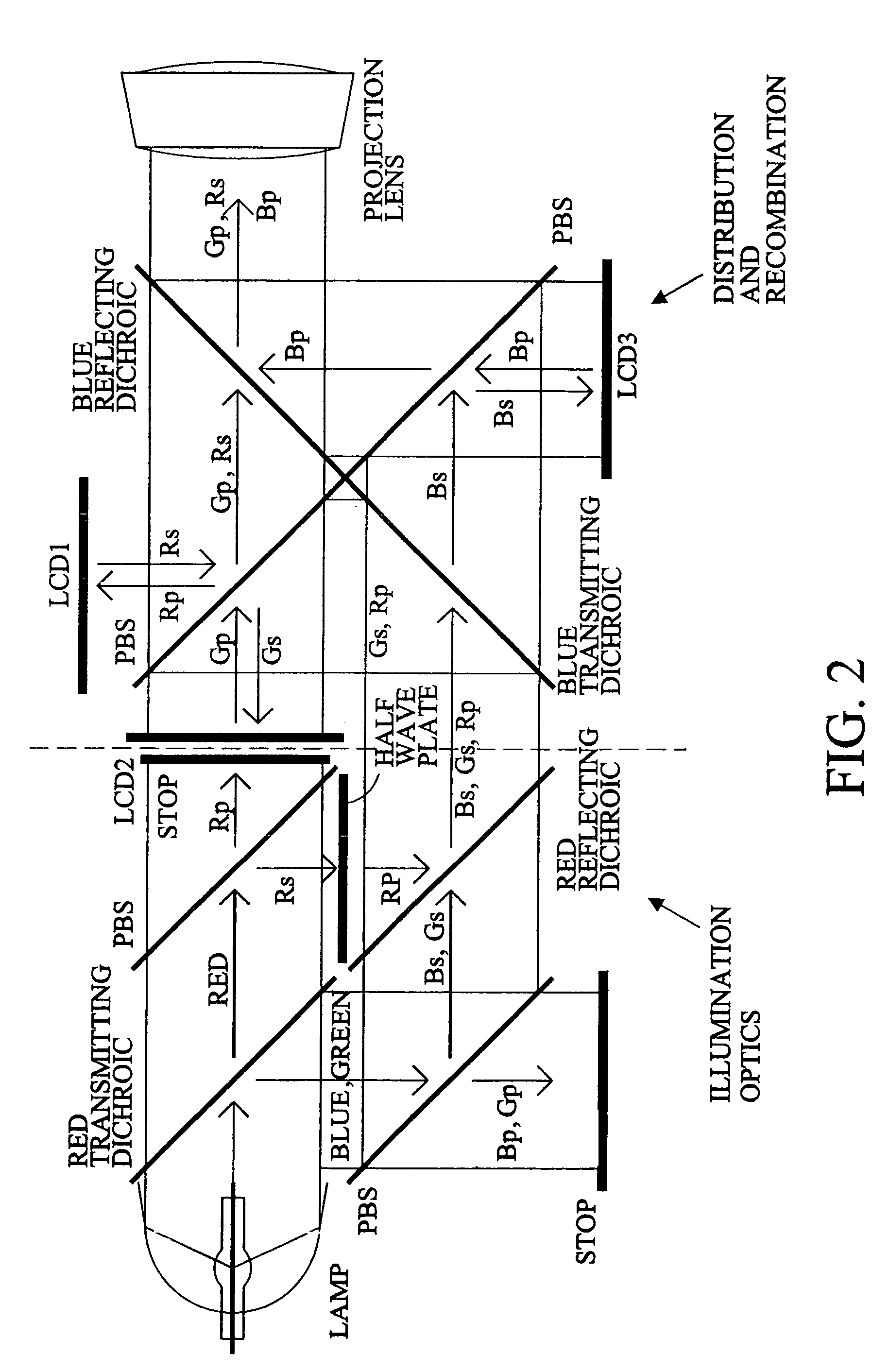

[0026] Referring now to the figures, wherein like numerals refer to like elements, FIG. 3 shows an exemplary projection display 10 having an illumination portion 11 and distribution and recombination portion 22. Distribution and recombination portion 22 includes three reflective liquid crystal display (LCD) panels 14, 16, and 18, also referred to as liquid crystal light valves.

[0027] Illumination portion 11 includes a light source 12 for producing white light, which may be separated into different color components of different bandwidths, such as a red color component, blue color component, and green color component. The white light from light source 12 passes through a polarization converter shown generally at 20. Polarization converter 20 may take the form of any conventional polarization converter, so that the randomly polarized light from light source 12 is converted into a single polarization state. In the embodiment shown in FIG. 3, the polarization converter 20 converts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com