Oil pump supporting structure of automatic transmission

a technology of automatic transmission and supporting structure, which is applied in the direction of gearing control, gearing elements, gearing ring, etc., can solve the problems of complex process for mounting the oil pump, large structure, and inability to reliably position the pump, so as to prevent vibration and noise of the oil pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be described in detail with reference to the drawings showing a preferred embodiment thereof.

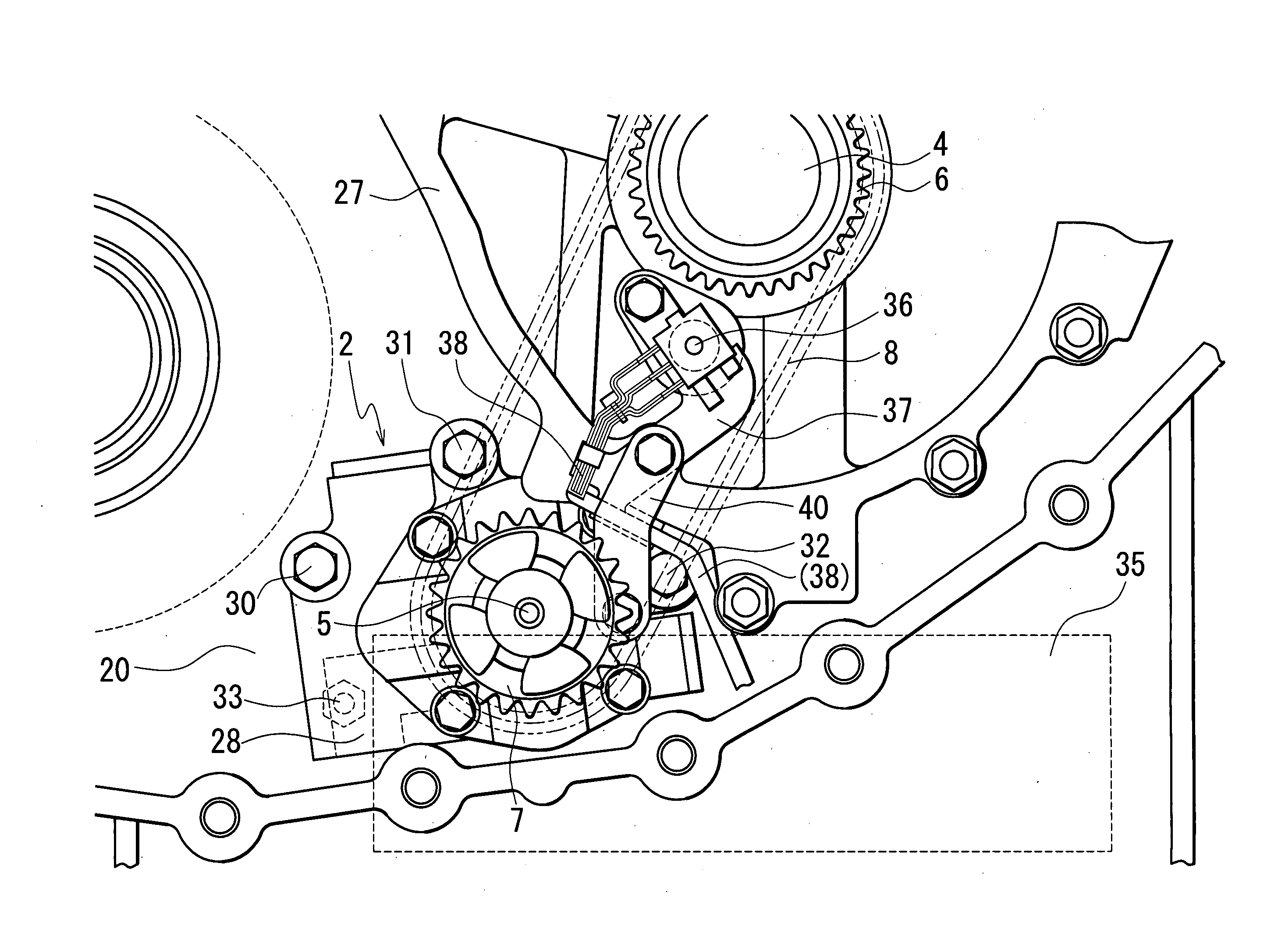

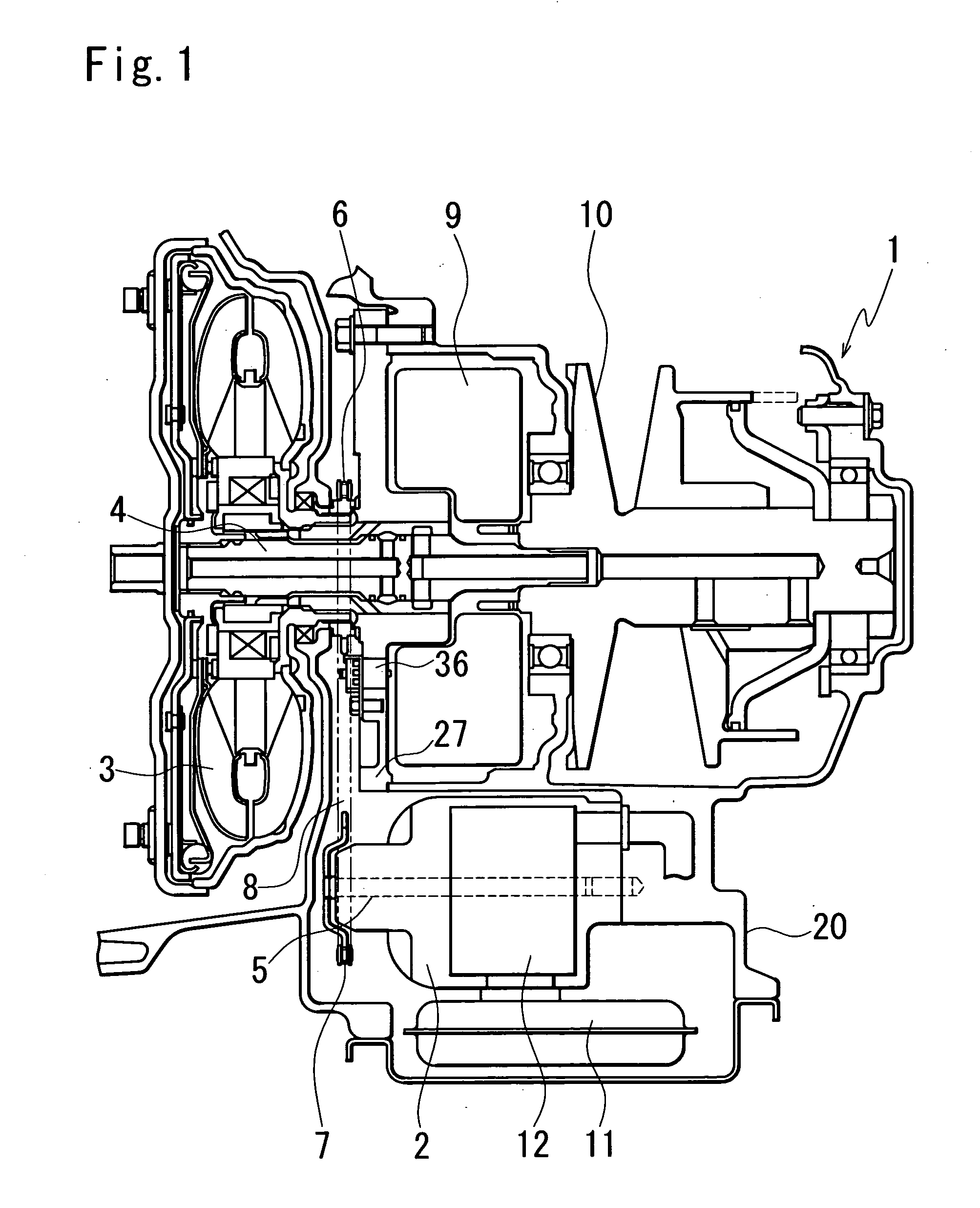

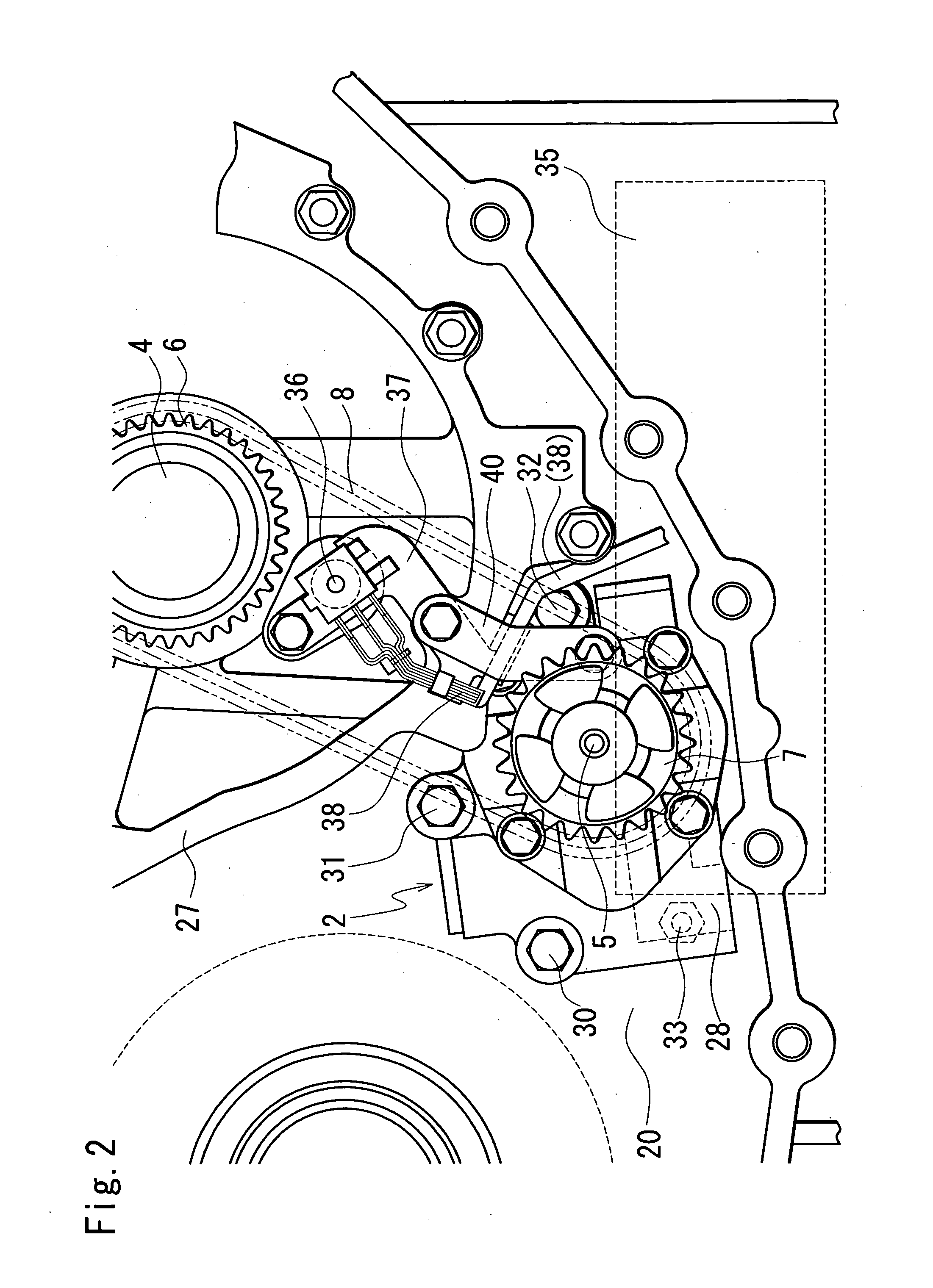

[0018]FIG. 1 is a sectional view showing an oil pump of a belt type continuously variable transmission and its vicinity according to an embodiment of the present invention. FIG. 2 is a front view showing the oil pump and its vicinity according to the embodiment.

[0019] A continuously variable transmission 1 to which power from an engine is input includes an input shaft 4 to which power is input from the engine via a torque converter 3, a forward / backward switching mechanism 9 that changes rotation directions of the power input to the input shaft 4, and a shift mechanism 10 that converts and transmits revolutions to wheels of a vehicle, not shown.

[0020] A vane type oil pump 2 driven by torque from the input shaft 4 is disposed such that an oil pump rotary shaft 5 and the input shaft 4 are in parallel with each other.

[0021] It is preferred that the vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com