Upright bent edge structure of a striking plate for combing with a golf club head body

a striking plate and bent edge technology, applied in the field of upright bent edge structure of striking plates, can solve the problems of increasing manufacturing costs, deteriorating elastic deformation of striking plates, and large number of unqualified golf club heads in manufacture, and achieve the effect of increasing design choi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

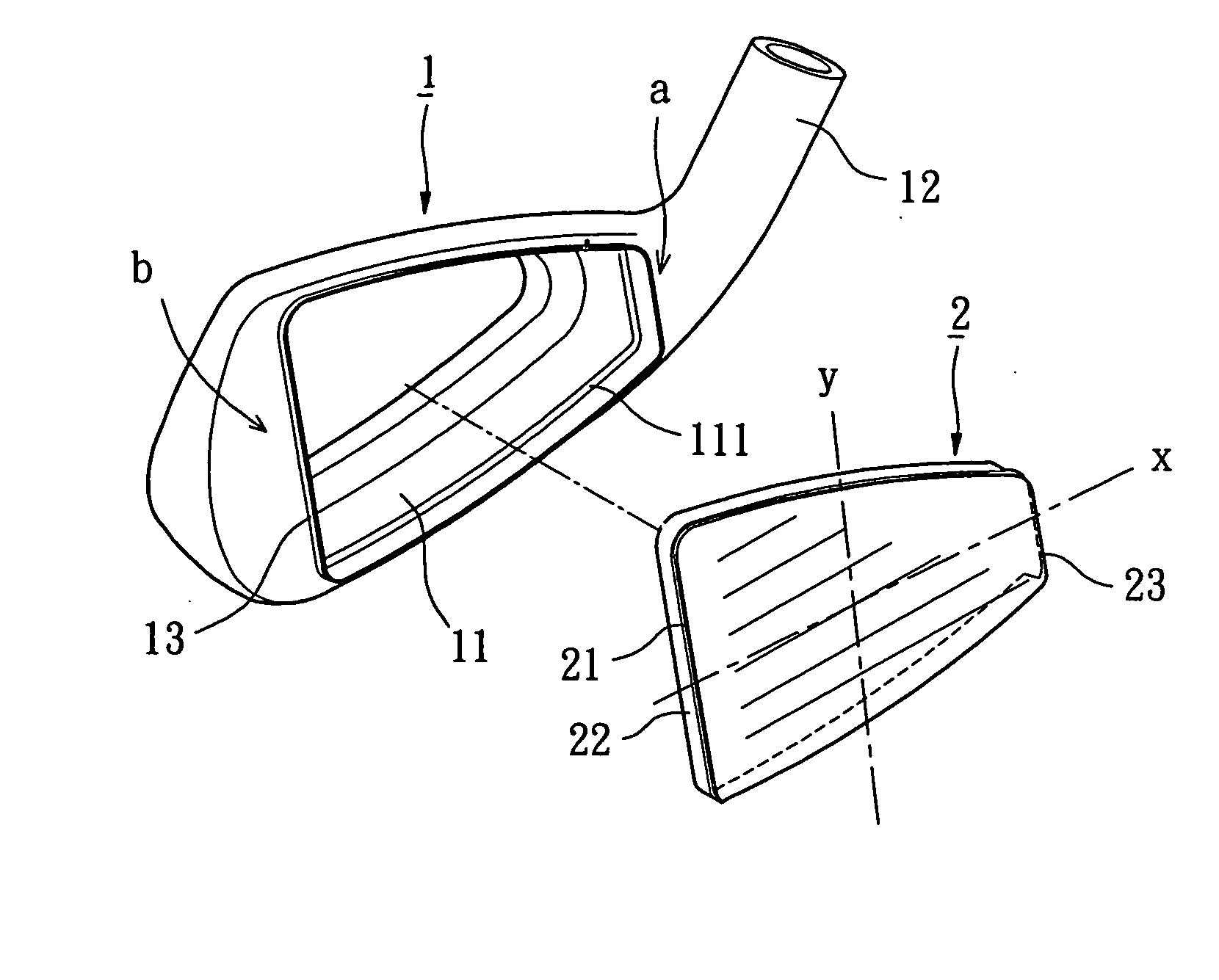

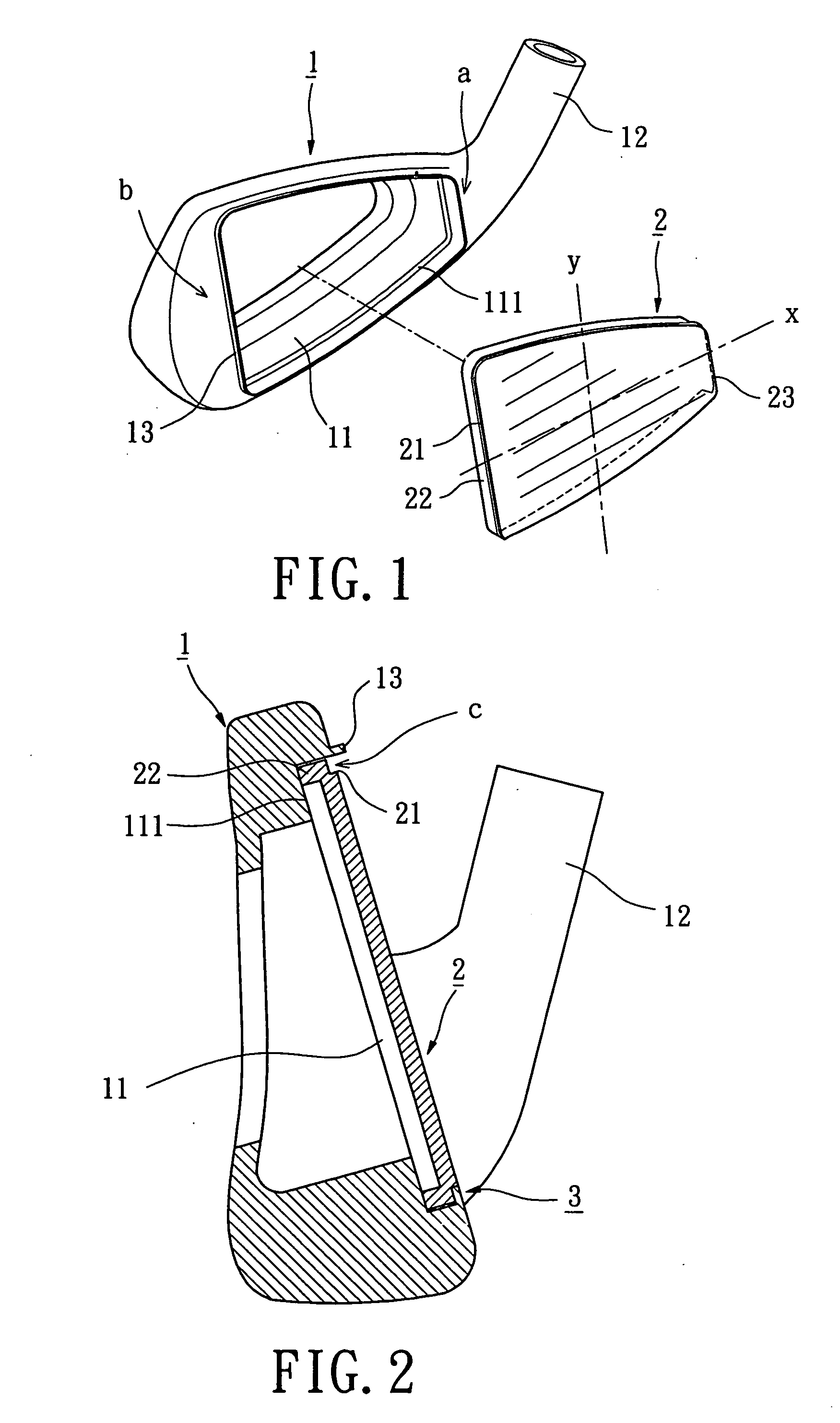

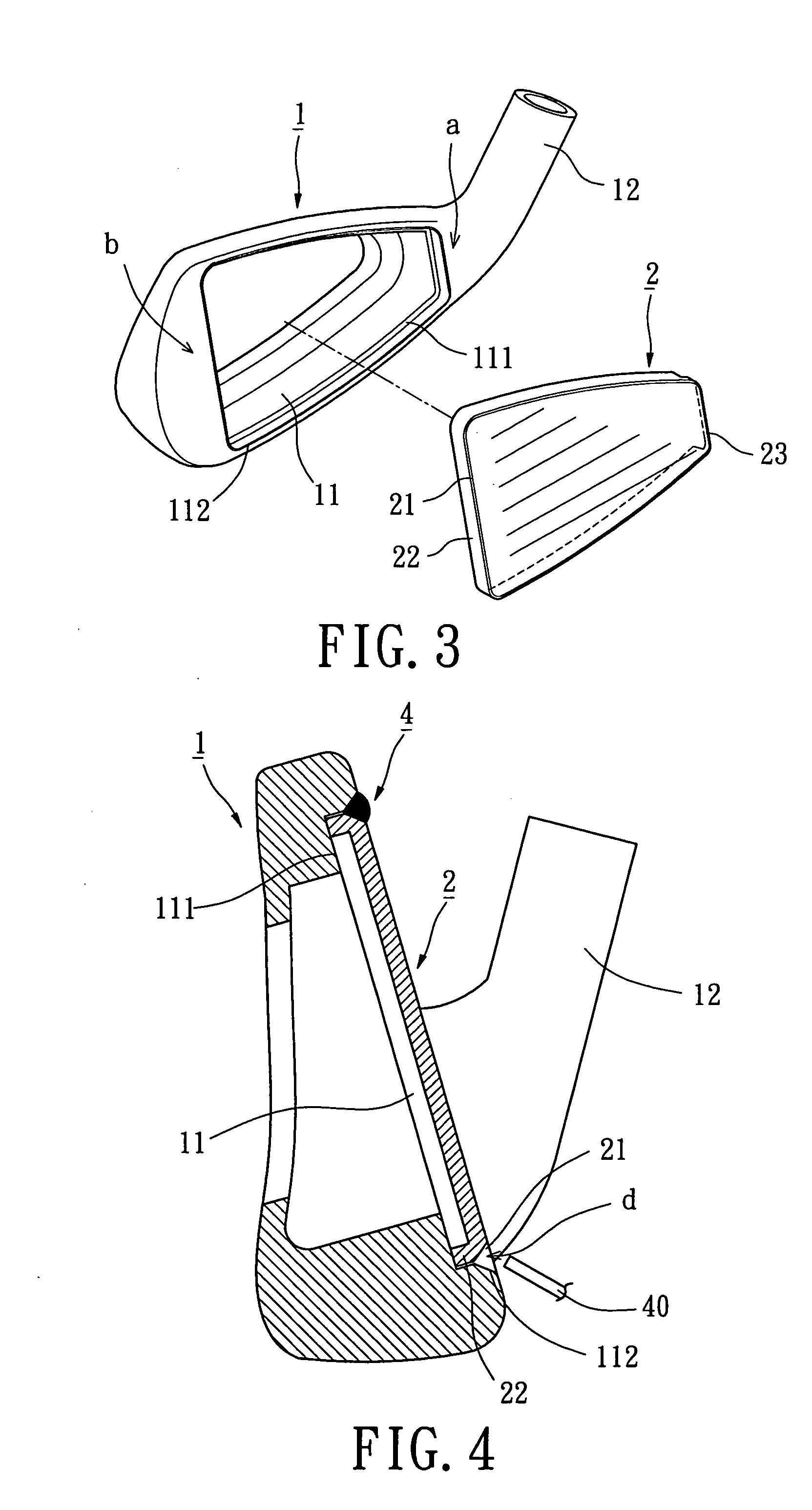

[0029] Referring initially to FIGS. 1 and 2, a golf club head in accordance with a first embodiment of the present invention generally includes a golf club head body member designated numeral 1 and a striking plate member designated numeral 2.

[0030] Referring again to FIG. 1, the construction of the golf club head body 1 shall be described in detail. The golf club head body 1 is made of stainless steel, carbon steel, alloy steel or Fe—Mn—Al alloy by casting, forging or mechanically pressing. The golf club head body 1 includes an assembling recession 11, a hosel 12 and an engaging protrusion 13. The golf club head body 1 forms the assembling recession 11 at its front side while selectively forming a sealing member or an opening at its rear side. The hosel 12 is used to securely receive an end of a shaft (not shown). The assembling recession 11 provides with a shoulder 111 extending on an inner surface.

[0031] The golf club head body 1 further includes a heel portion as indicated at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com