Compound forming fabric with additional bottom yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

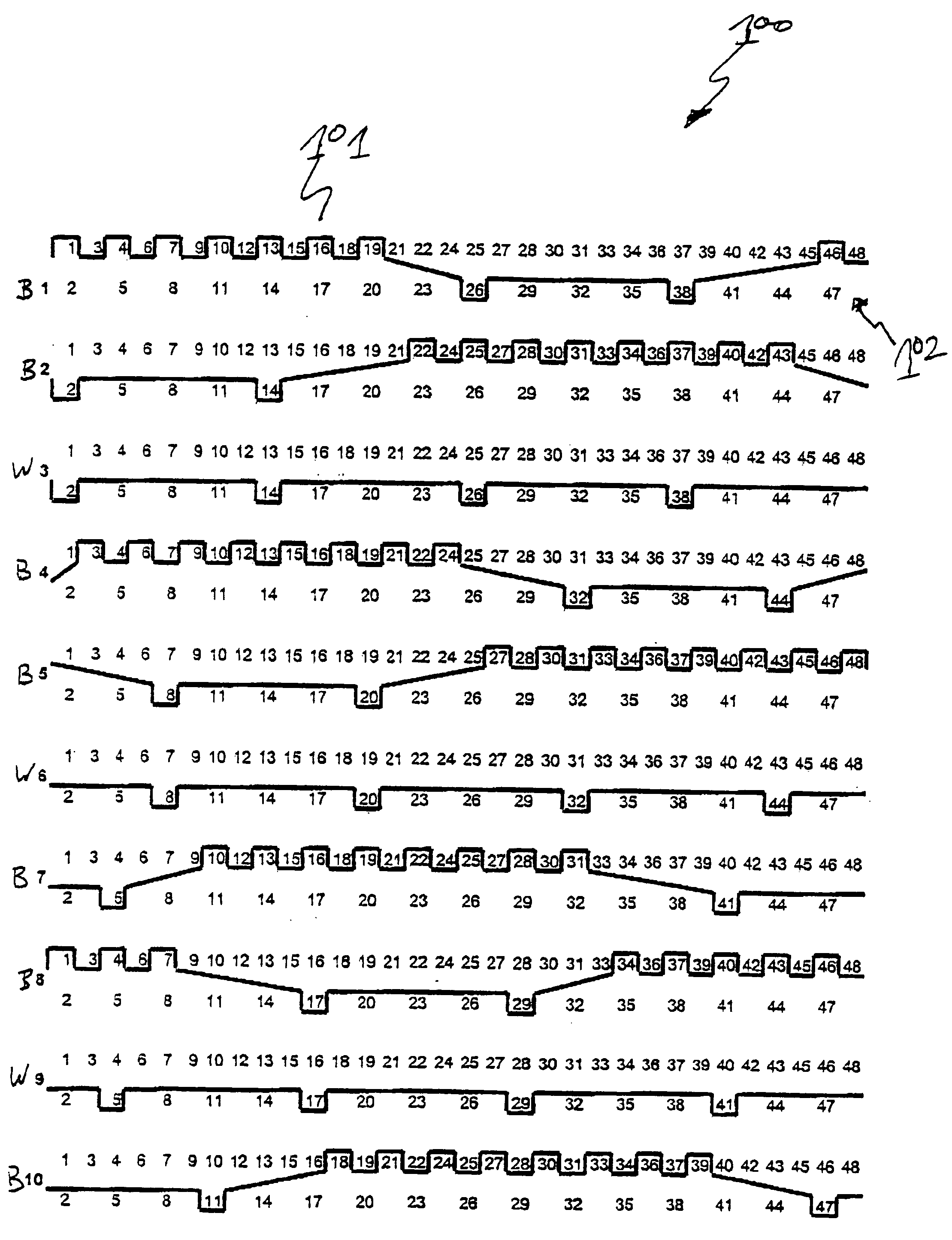

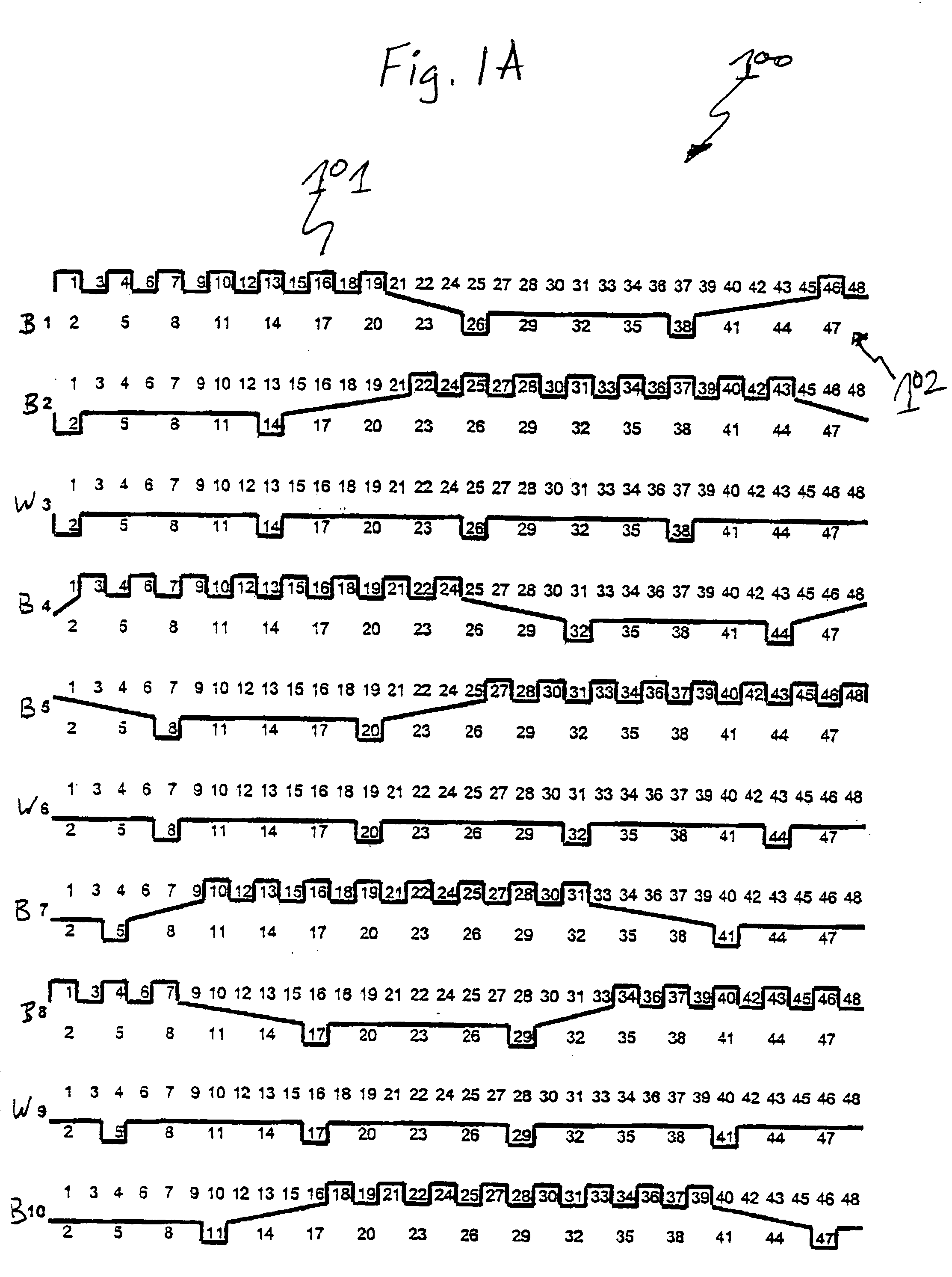

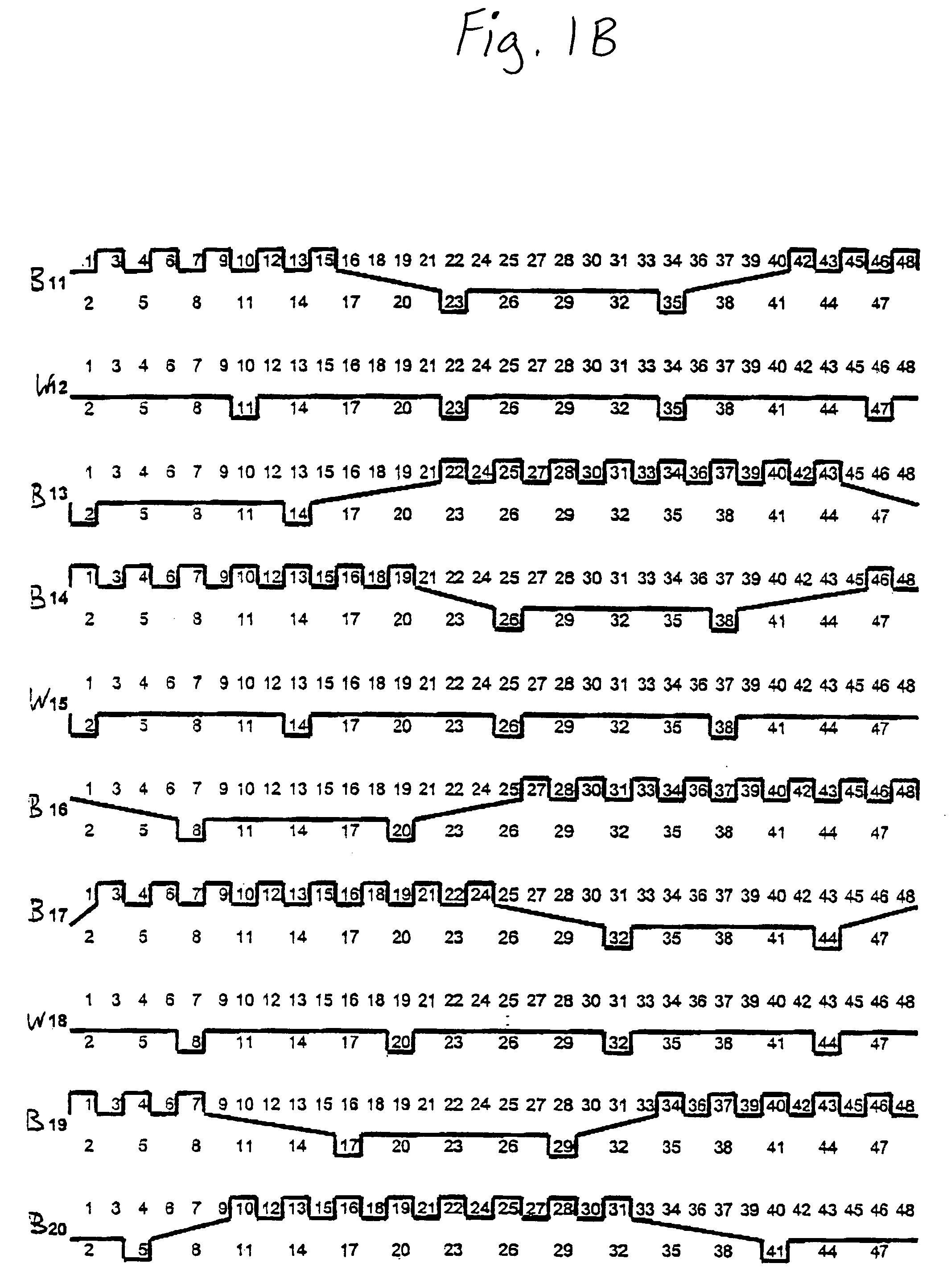

[0025] Referring now to the sole drawing, FIGS. 1A, 1B and 1C, there is shown a compound forming fabric 100 having a weave repeat of 24 warp yarns and 48 weft yarns. Fabric 100 includes binder warp yarns B1, B2, B4, B5, B7, B8, B10, B11, B13, B14, B16, B17, B19, B20, B22 and B24 which are arranged in pairs B1, B2 and B4, B5 and B7, B8 and so on.

[0026] Fabric 100 includes top weft yarns 1, 3, 4, 6, 7, 9, 10, 12, 13, 15, 16, 18, 19, 21, 22, 24, 25, 27, 28, 30, 31, 33, 34, 36, 37, 39, 40, 42, 43, 45, 46 and 48 and bottom weft yarns 2, 5, 8, 11, 14, 17, 20, 23, 26, 29, 32, 35, 38, 41, 44 and 47.

[0027] Further, fabric 100 includes bottom warp yarns W3, W6, W9, W12, W15, W18, W21 and W24.

[0028] Fabric 100 has a top weave 101 and a bottom weave 102. Top weave 101 is a plain weave. Top weave 101 of fabric 100 is formed by the weaving of the interchanging binder yarns B1, B2, B4, B5, etc. with the top weft yarns 1, 3, 4, 6, 7, 9, 10, 12, 13, 15, 16, 18, 19, 21, 22, 24, 25, 27, 28, 30, 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com