Model 1911 type firearm safety lock

a safety lock and pistol technology, applied in the field of pistols, to achieve the effect of effective means of locking down a firearm and easy replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

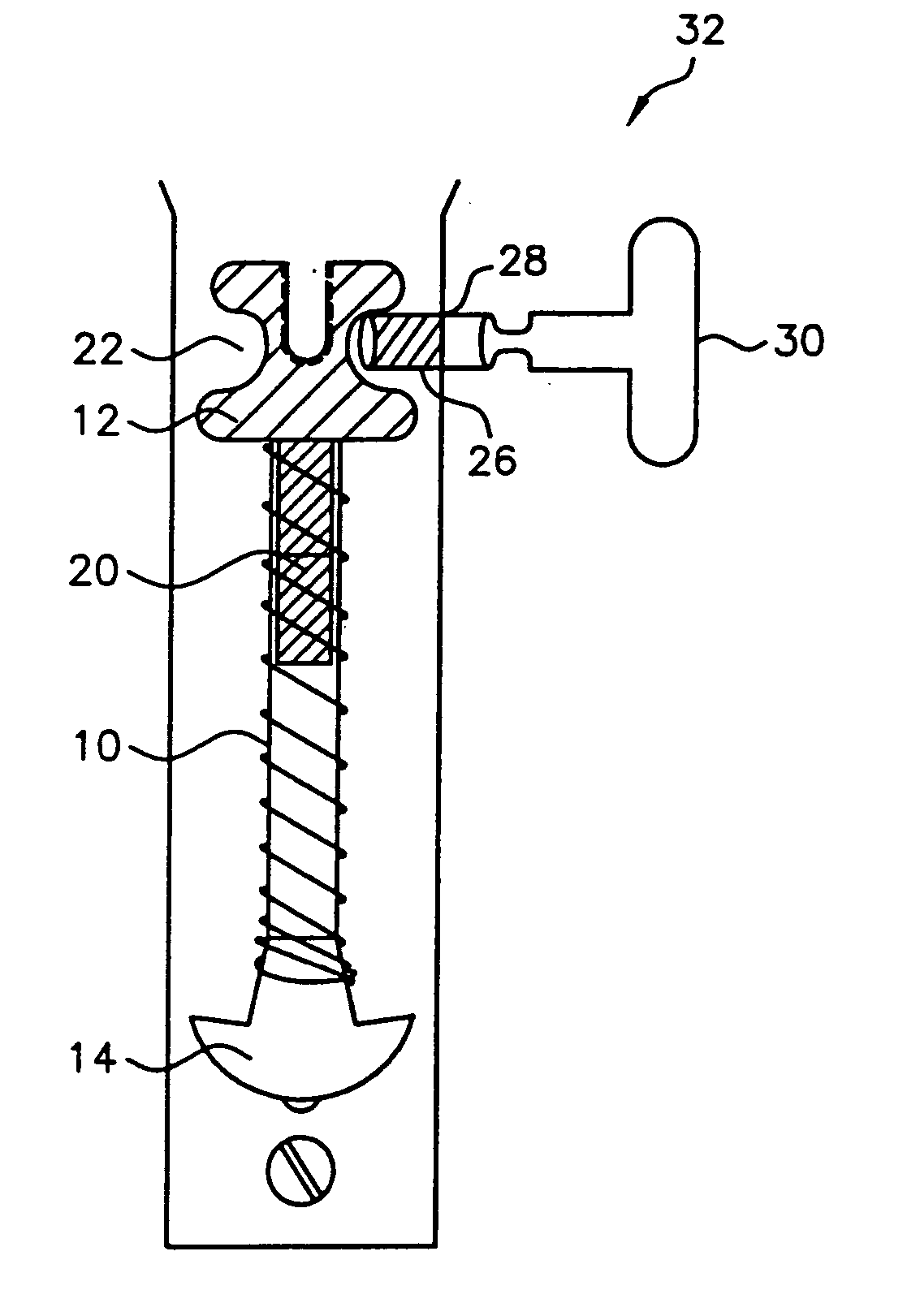

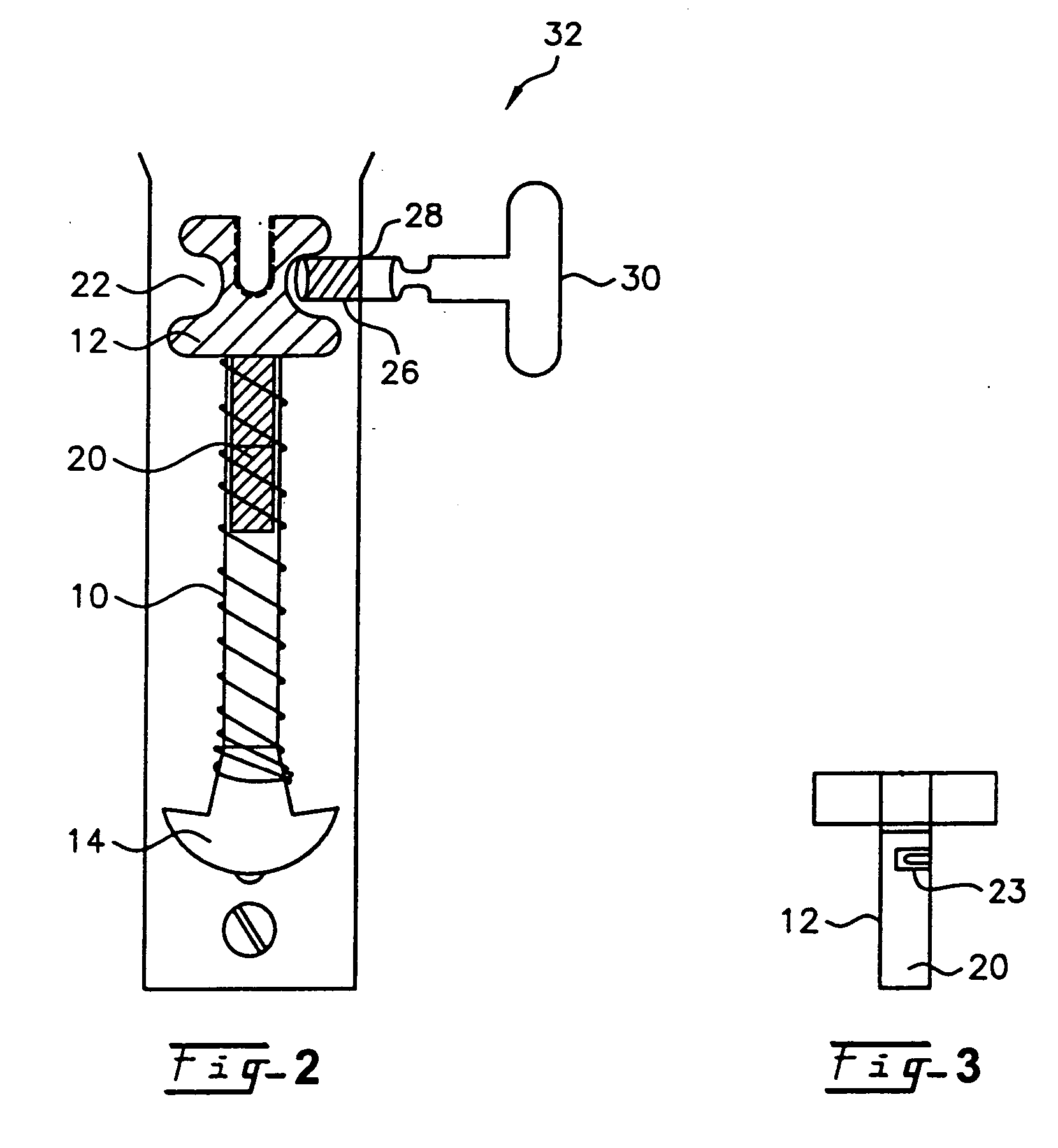

[0012] The invention will now be described with reference to the various figures in which like numbers refer to like parts for a typical model 1911 style handgun. Turing to FIG. 1, an exploded view of the pistol is seen utilizing parts which will seem familiar to gunsmiths and those skilled in the art. Turning to area 38 shown on FIG. 1, it will be appreciated by those familiar with firearms that a 1911 model semiautomatic handgun utilizes a main spring contained within the pistol grip area of the handgun. The hammer 8 is attached to the trigger spring operating rod 18. FIG. 1 discloses the operating rod separately in the exploded view, through it would be appreciated by those skilled in this art that rod 18 sits within an upper notch area of buffer 12 when the pistol is assembled. Upon cocking of the hammer 8, rod 18 presents force in the downward position and urges buffer 12, sitting within the coil of the spring 10, to compress or bias the spring. The compressed spring provides t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com