Reinforcing steel support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

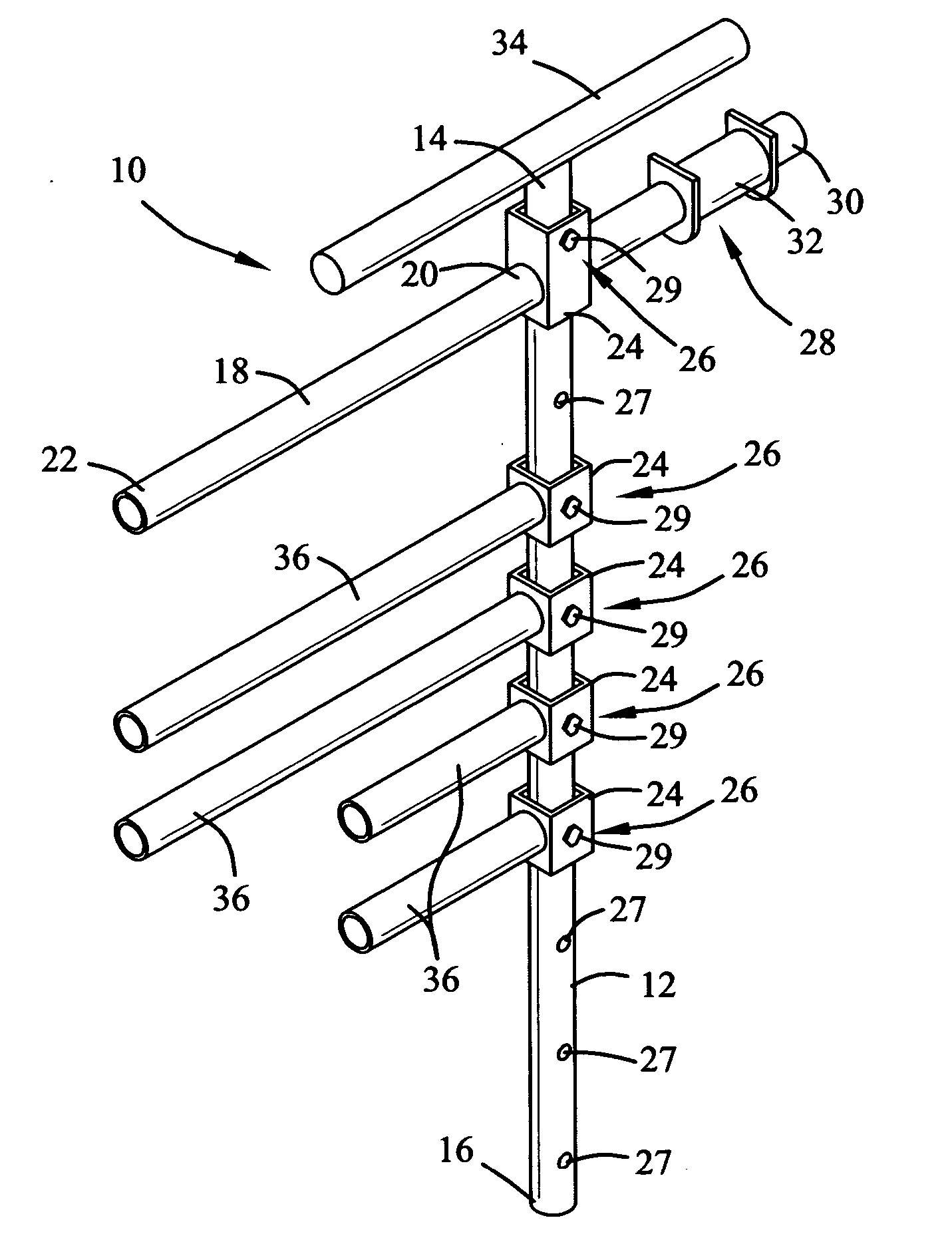

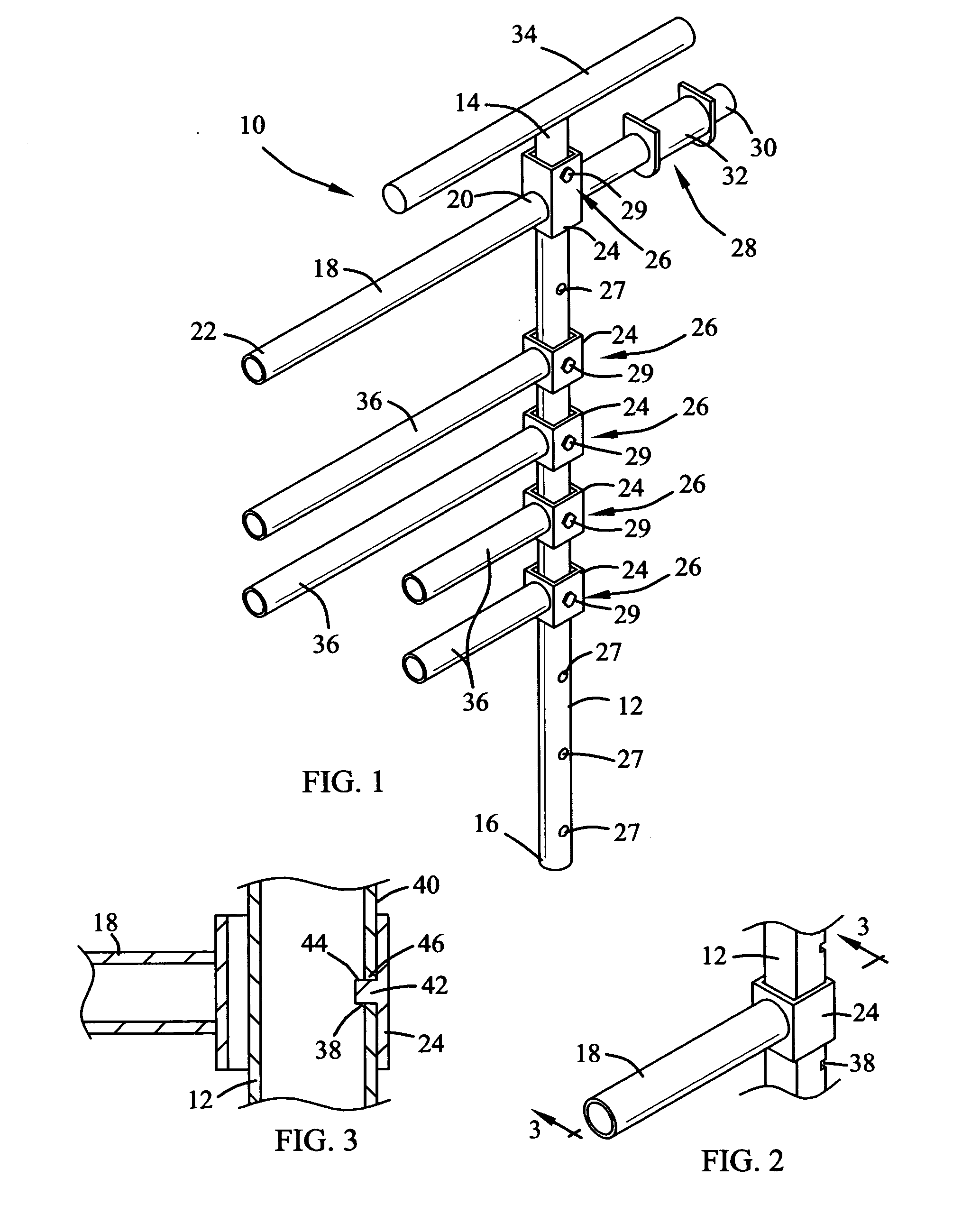

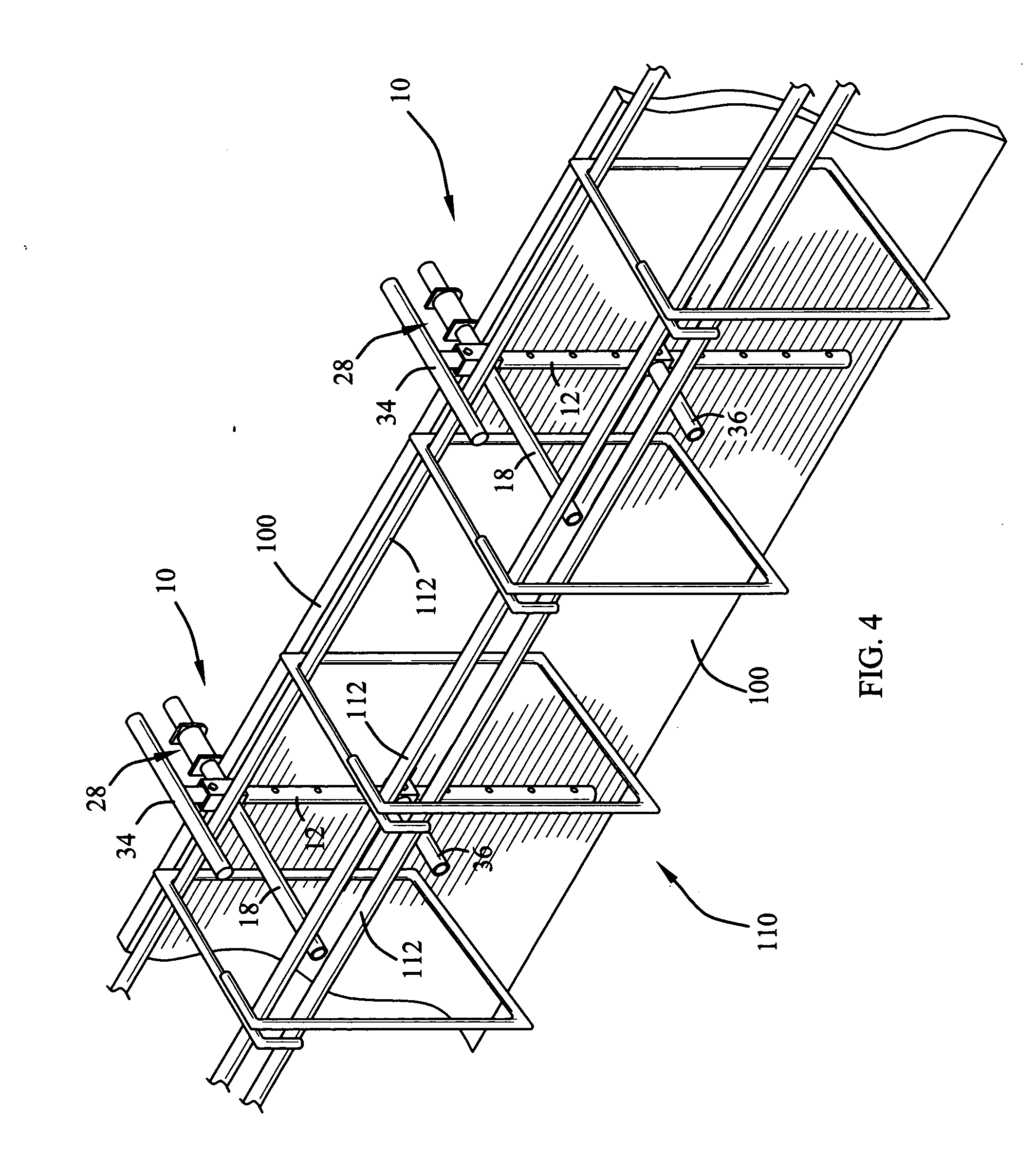

[0020] Referring now to the drawings, and particularly to FIGS. 1-2, a preferred embodiment of the support for reinforcing steel of the present invention is shown and generally designated by the reference numeral 10.

[0021] Referring to FIG. 1, the support 10 includes a vertical member 12 having a first end 14 and a second 16. Preferably, the vertical member 12 is of a tubular section of a circular cross-section. A support arm 18 extends from and orthogonal to the vertical member 12 at a selected position or elevation between the first and second ends 14 and 16. Preferably, the support arm 18 is of a cantilever type and is only supported by the vertical member 12 at one end 20 with the opposite end 22 projecting in a direction away from the vertical member. Most preferably, the support arm 18 is of a tubular section. The end 20 of the support arm 18 can define a channel section 24 which is adapted to slidably receive the vertical member 12 so that the support arm can be selective po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com