Container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

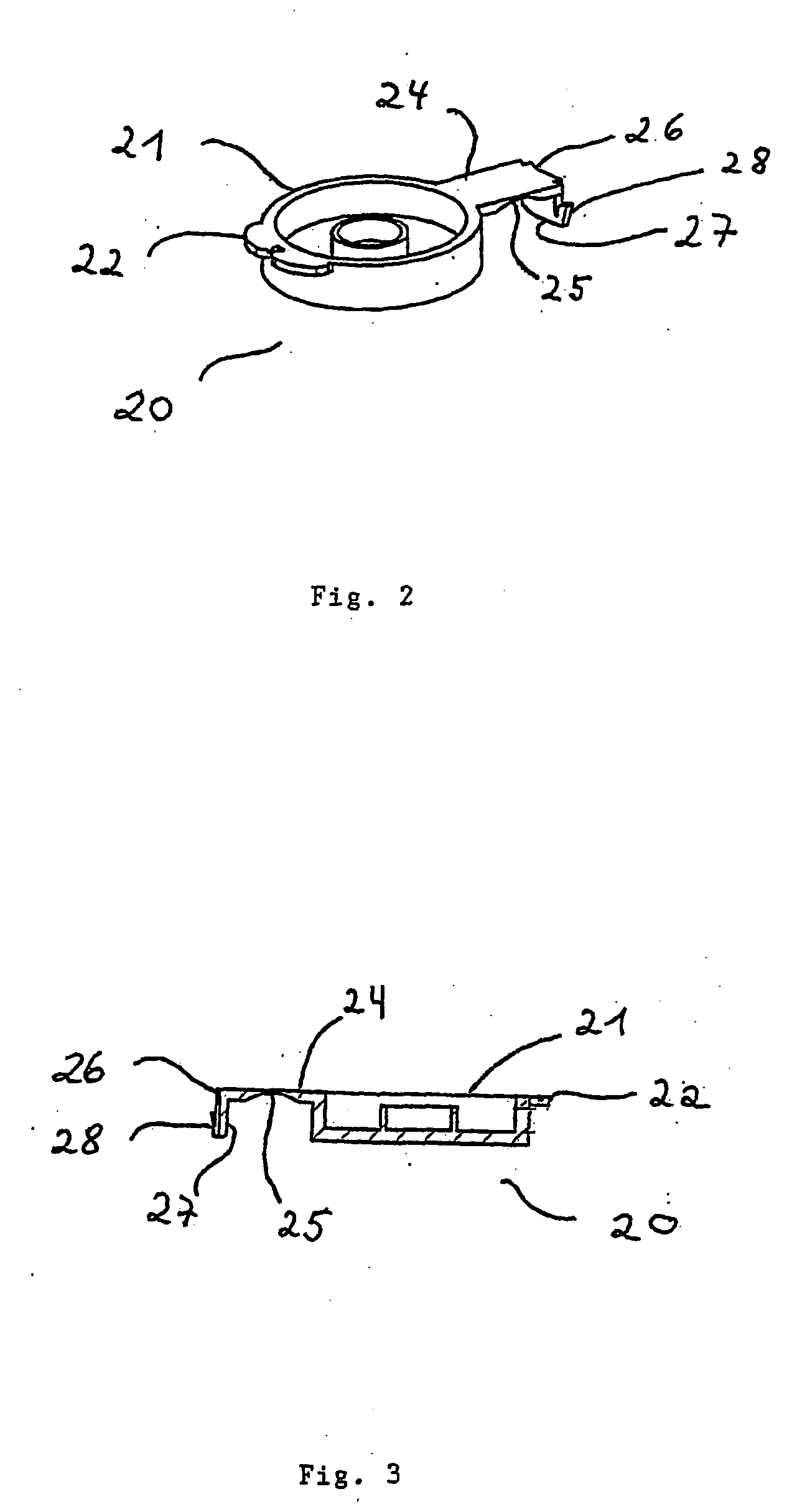

[0026] The material used both for the container body and for the lid is polypropylene, which can be processed in the range from 200 to 300° C. In order to facilitate the formation of the film hinge on the connecting land of the lid, the polypropylene for the lid can also have a conventional commercially available plasticiser added to it.

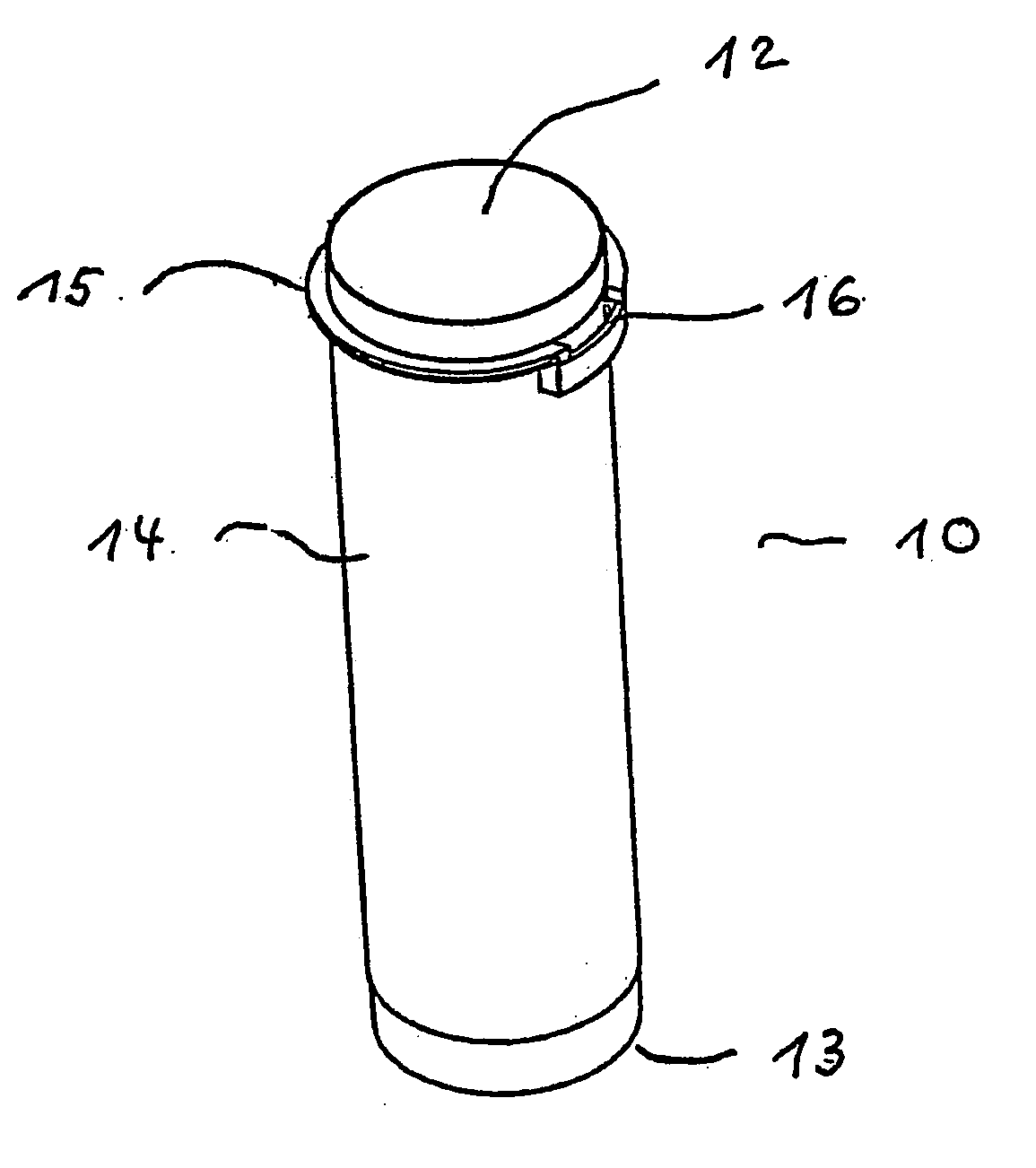

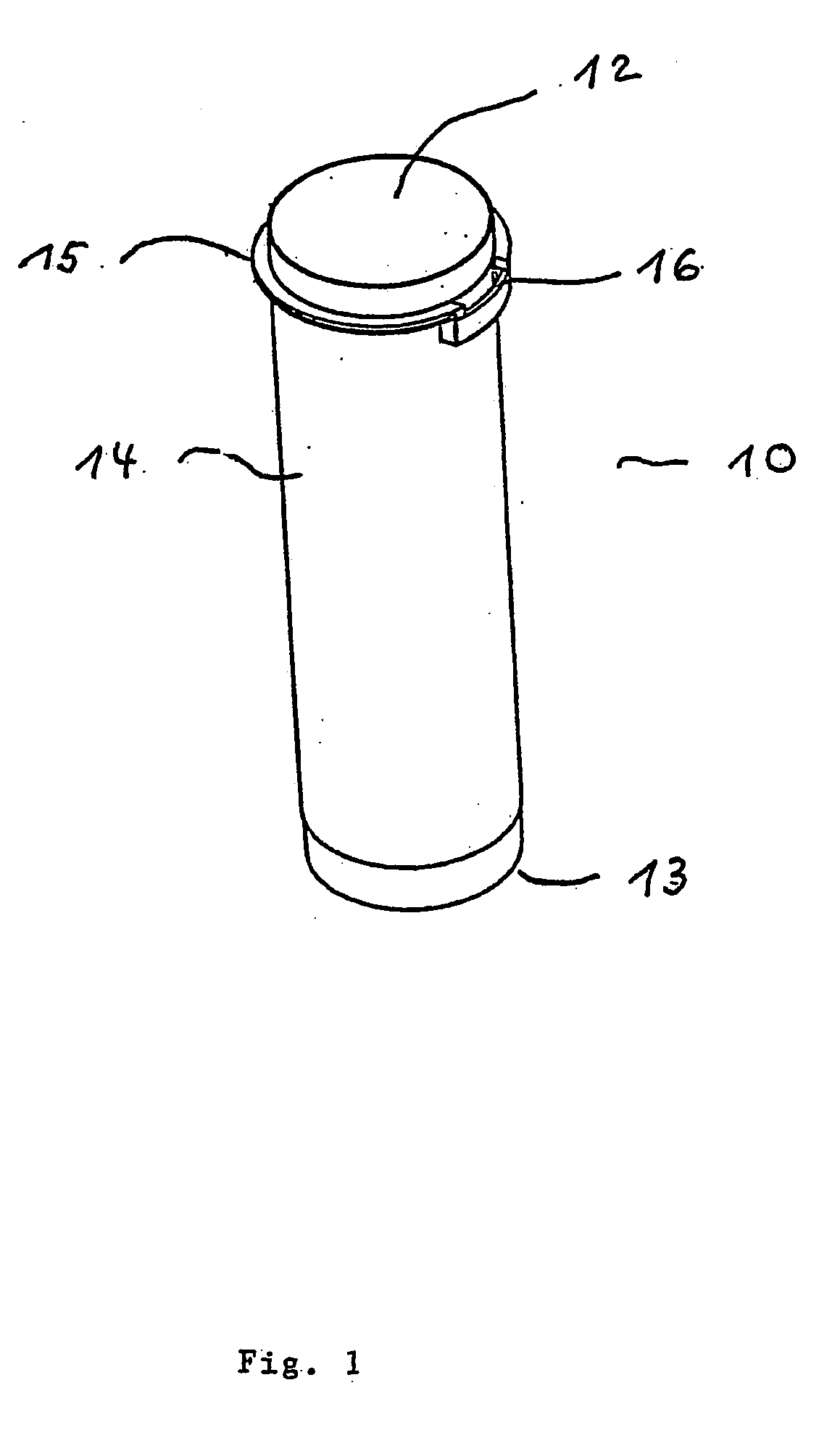

[0027] The container body, which is cylindrical in the case of this example, and the rounded lid, the dimensions of which have been adapted to the body shape, are produced in two separate moulds, with a plurality of each part being contained in a mould. A conventional injection moulding process is used for production.

[0028] After the injection process, the parts are ejected mechanically onto a belt by means of a scraper. The two parts are delivered separately to an assembly station, where they are aligned and subjected to a handling process in which the two parts are brought together. After that, the closure is performed mechanically. The injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com