Sterile cleaning kit

a sterile cleaning and cleaning solution technology, applied in the field of cleaning solutions, can solve the problems of increasing costs, reducing effectiveness, and reducing and achieve the effects of reducing waste and associated costs, reducing waste, and ensuring the effect of disinfectant transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

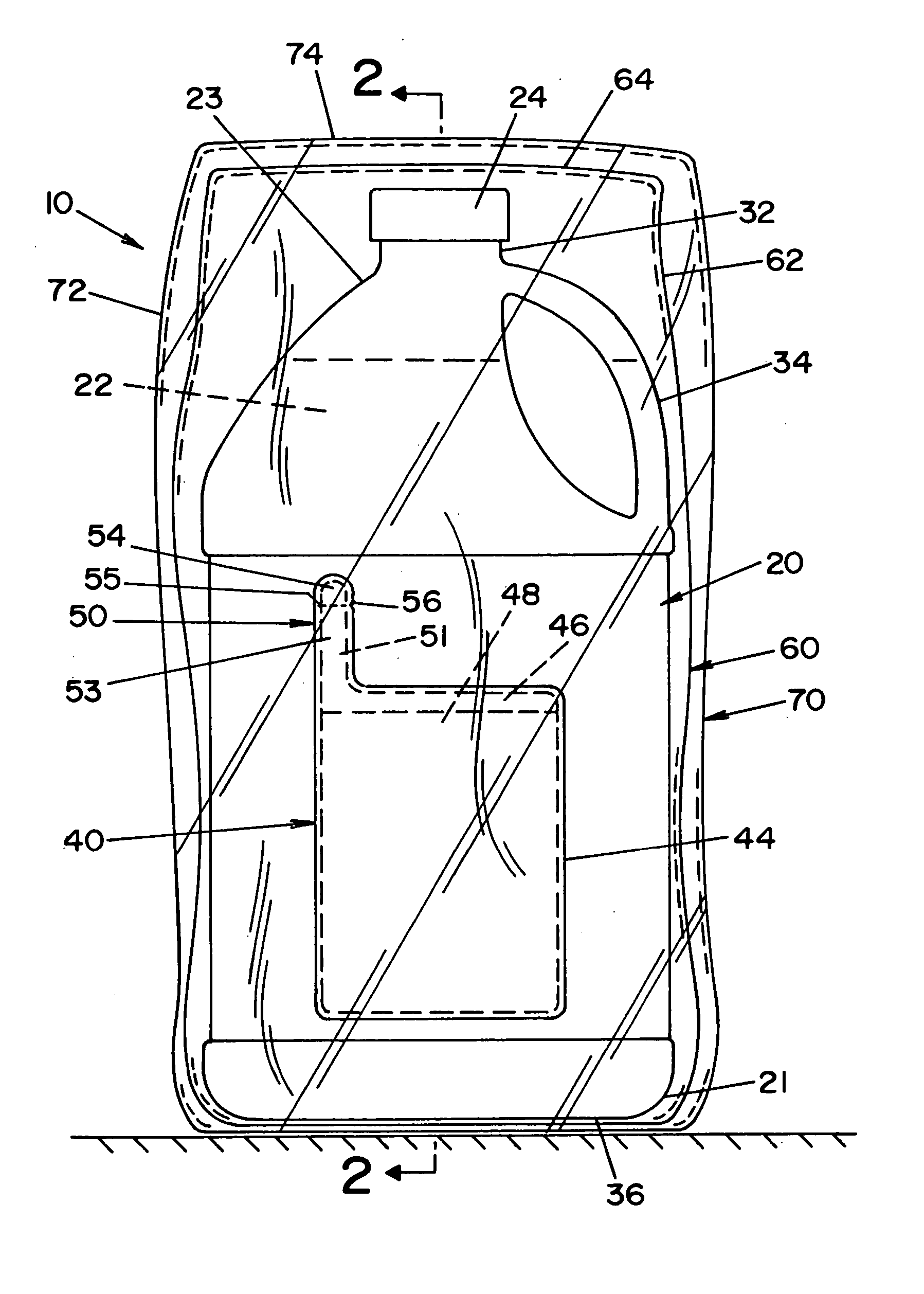

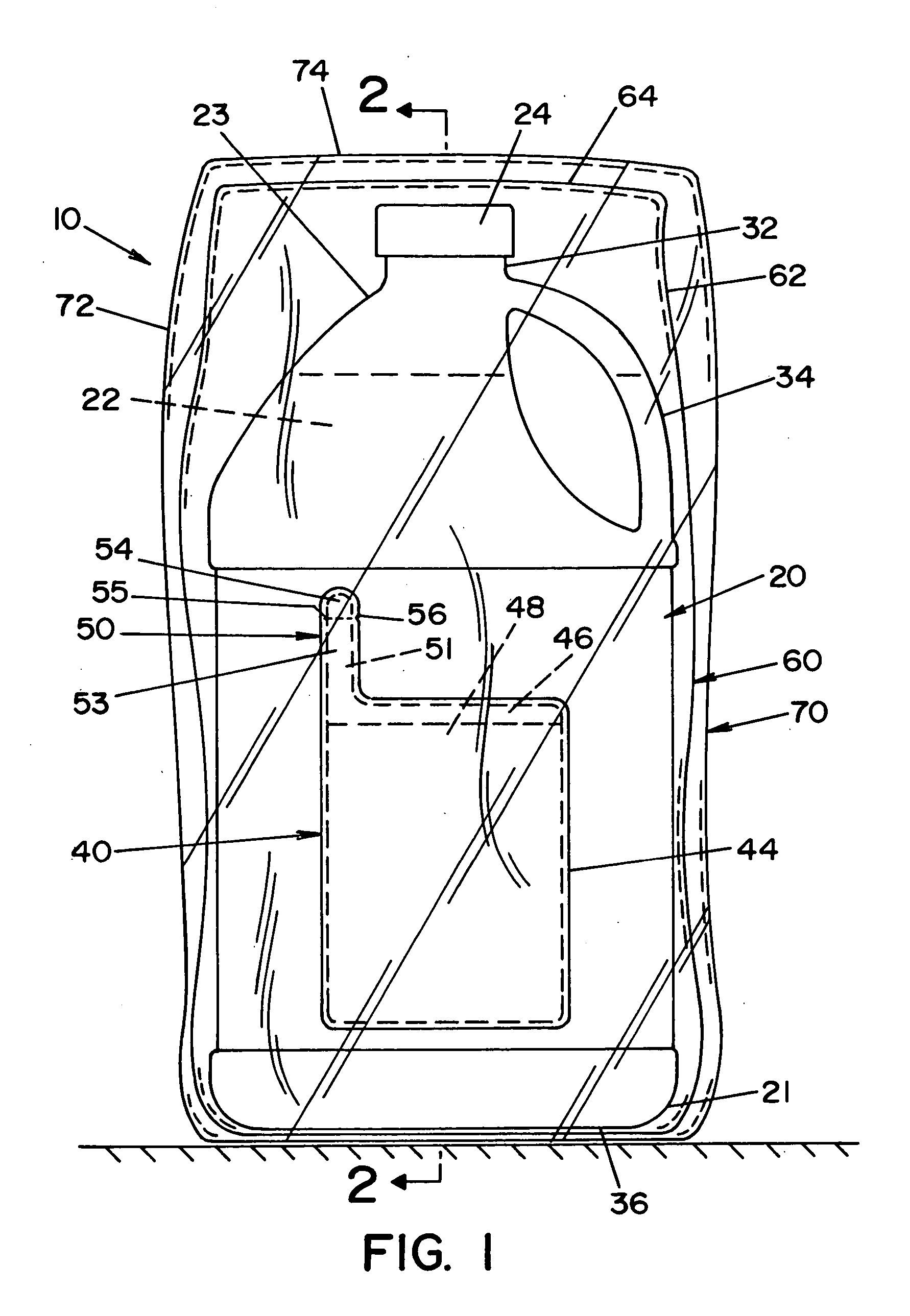

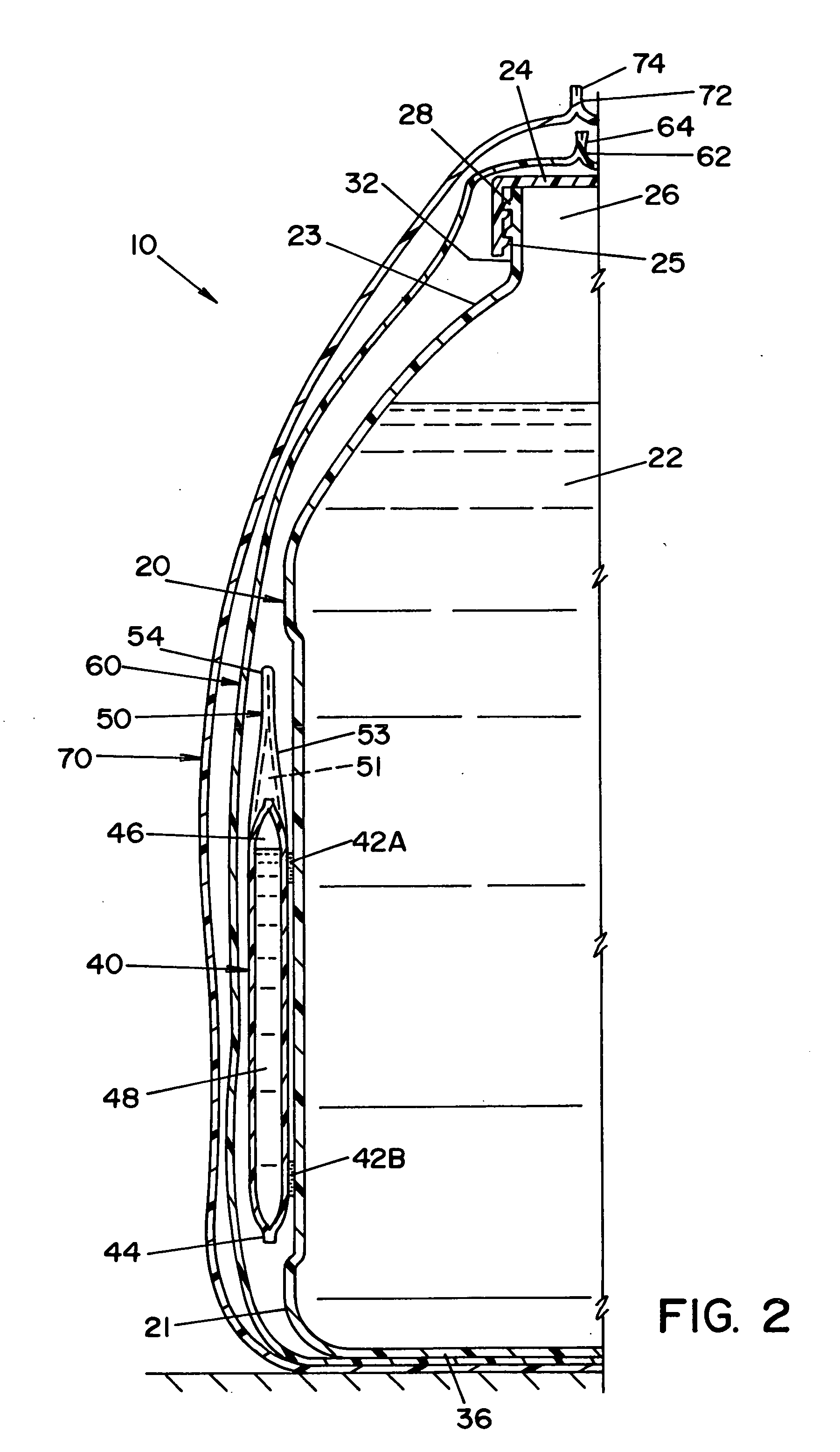

[0020] Referring now to the drawings wherein the showings are for the purposes of illustrating a preferred embodiment of the present invention only and not for the purposes of limiting same, FIG. 1 shows a sterile solution kit 10 for creating (forming) a sterile cleaning solution. Broadly stated, sterile solution kit 10 is comprised of a container 20, a packet 40, an inner bag 60 and an outer bag 70.

[0021] In the embodiment shown, container 20 is generally cylindrical or rectangular in shape and has a closed bottom end 21 and an open upper end 23. Upper end 23 of container 20 is formed to define a throat 32 and a handle 34. Container 20 is a rigid or soft-sided container wherein throat 32 and handle 34 are integrally formed. Bottom end 21 of container 20 defines a support surface 36. Support surface 36 is formed to allow container 20 to be free standing on a flat surface. An option may be to package a soft sided container that has other features designed to make it stable on a flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

| surface feature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com