Method for setting response modes of construction vehicle operation lever

a technology for operation levers and construction vehicles, applied in mechanical devices, constructions, couplings, etc., can solve problems such as and affecting the operation of construction vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment of the present invention will be described herein below with reference to the accompanying drawings. In the following description, well-known functions or constructions are not described in detail since they would obscure the invention in unnecessary detail.

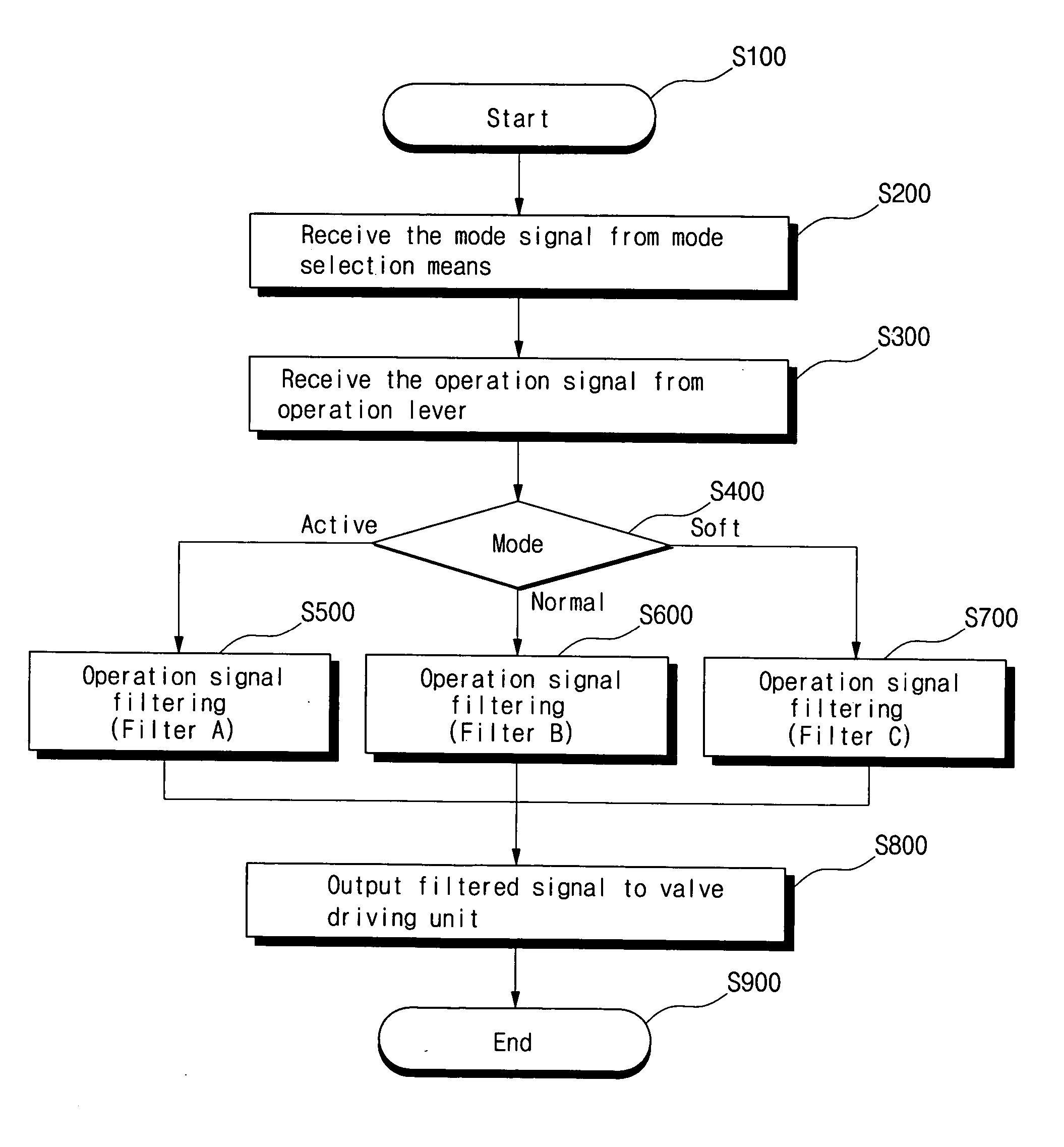

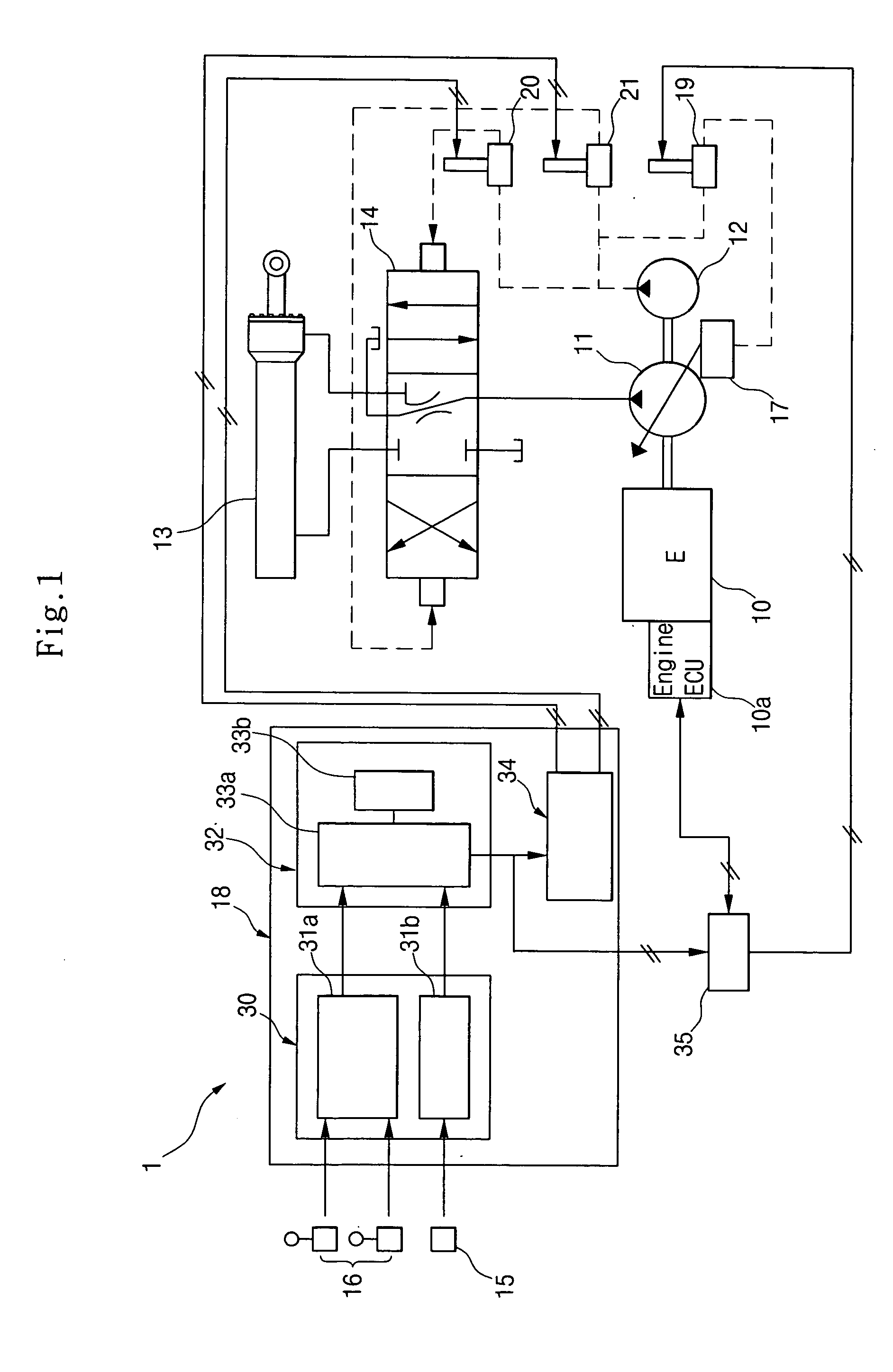

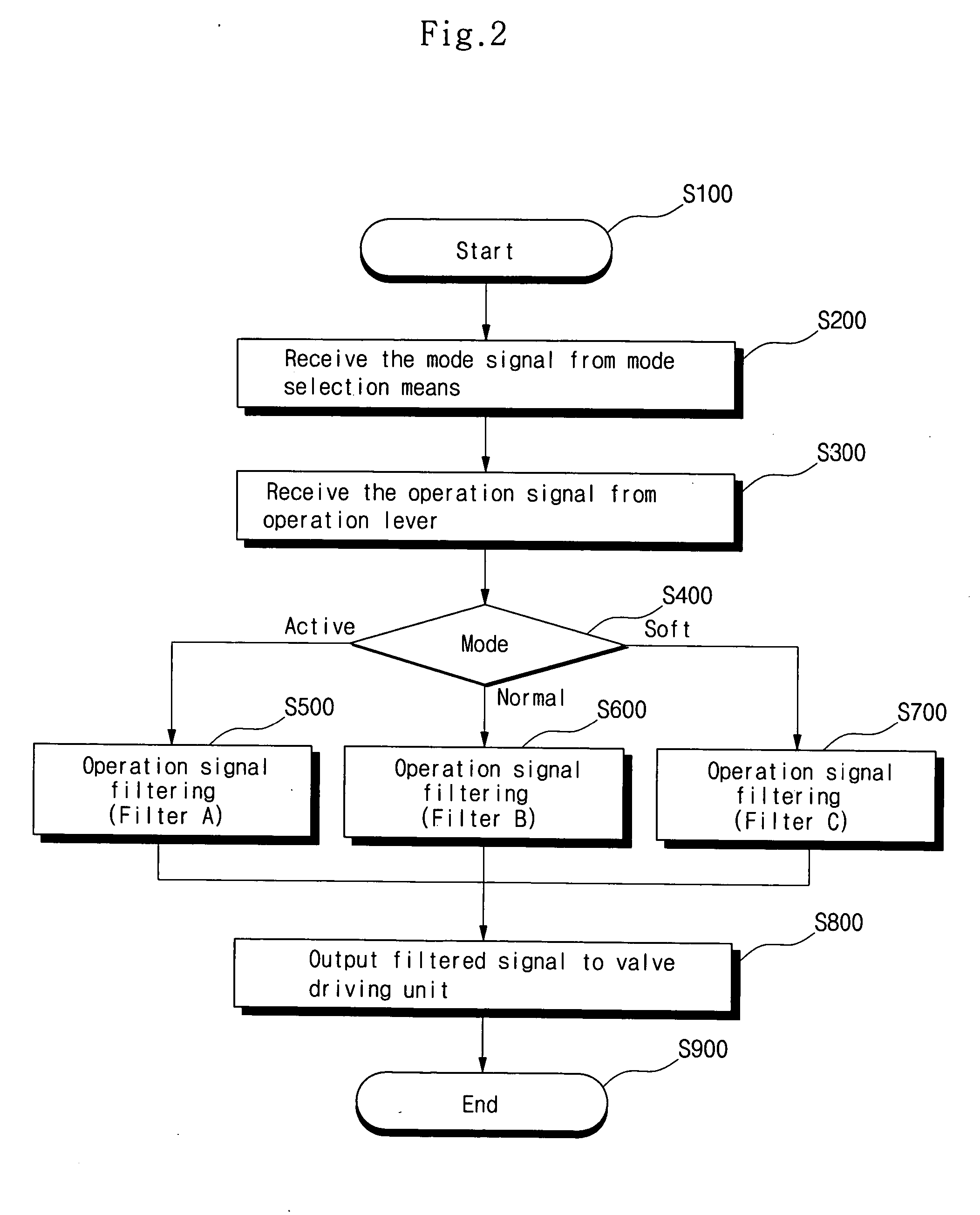

[0022]FIG. 1 is a schematic diagram of a hydraulic system to which a method for setting response modes of an operation lever according to one embodiment of the present invention is applied.

[0023] The hydraulic system to which a method for setting response modes according to one embodiment of the present invention is applied includes hydraulic pump 11 driven by an engine 10, an actuator 13 for driving a working apparatus (not shown) using hydraulic fluid supplied from the hydraulic pump 11, a control valve 14 for supplying the hydraulic fluid in the hydraulic pump 11 to the actuator 13, an operation lever 16 for generating an operation signal to drive the actuator 13, a controller 18 for changing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com