Welding machine with automatic parameter setting

a welding machine and automatic parameter technology, applied in the field of welding machines, can solve the problems of improper selection of setup parameters by operators, poor quality welds, and inefficient use of welding machines or consumables,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

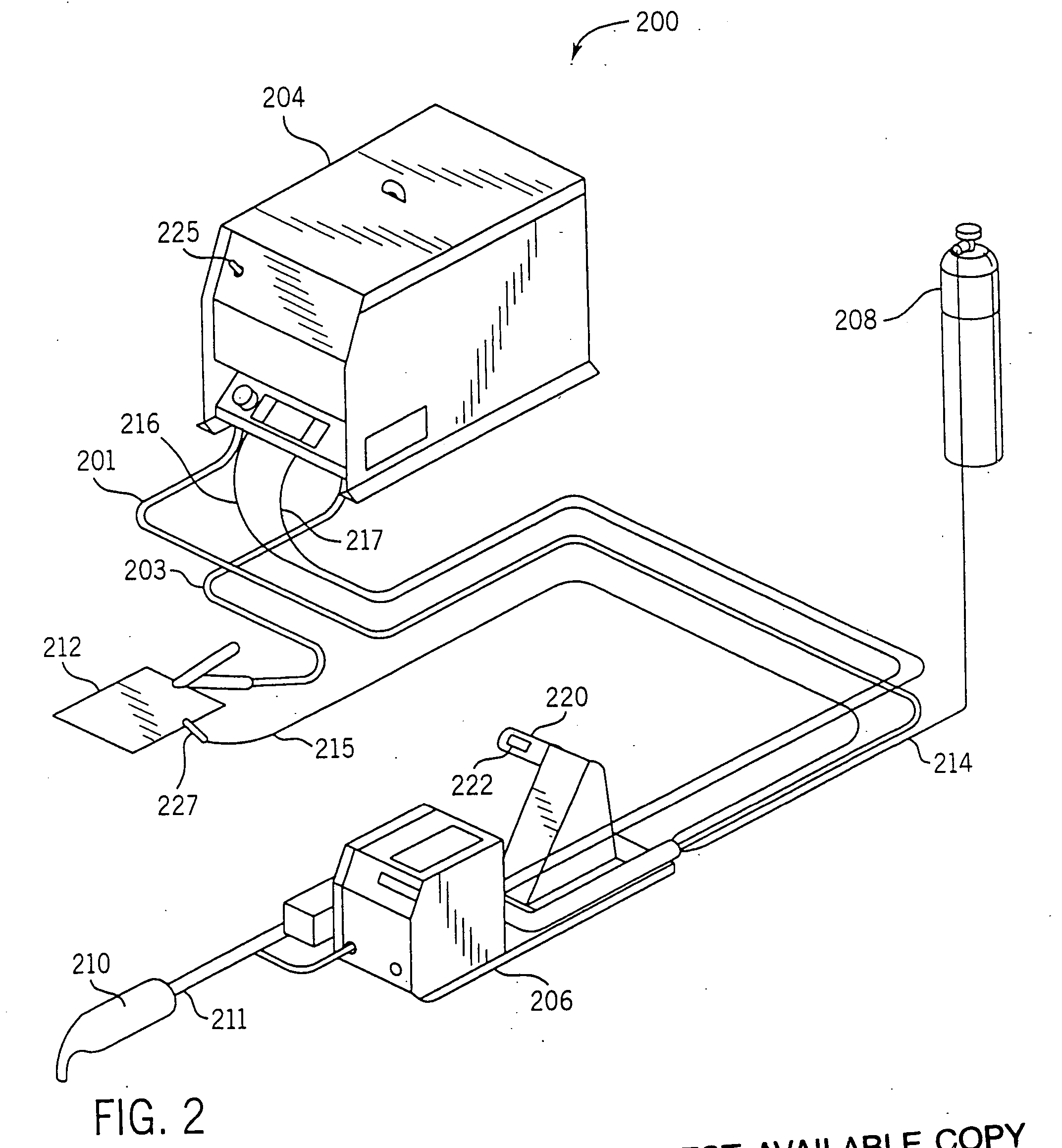

[0016] While the present invention will be illustrated with reference to a welding machine having a separate wire feeder and power source, it should be understood at the outset that the inventive welding machine with automatic parameter selection may also be implemented with other types of welding machines, including those that have the wire feeder and power source integrated into a single housing. Also, the invention is not limited to the particular types of sensors discussed below.

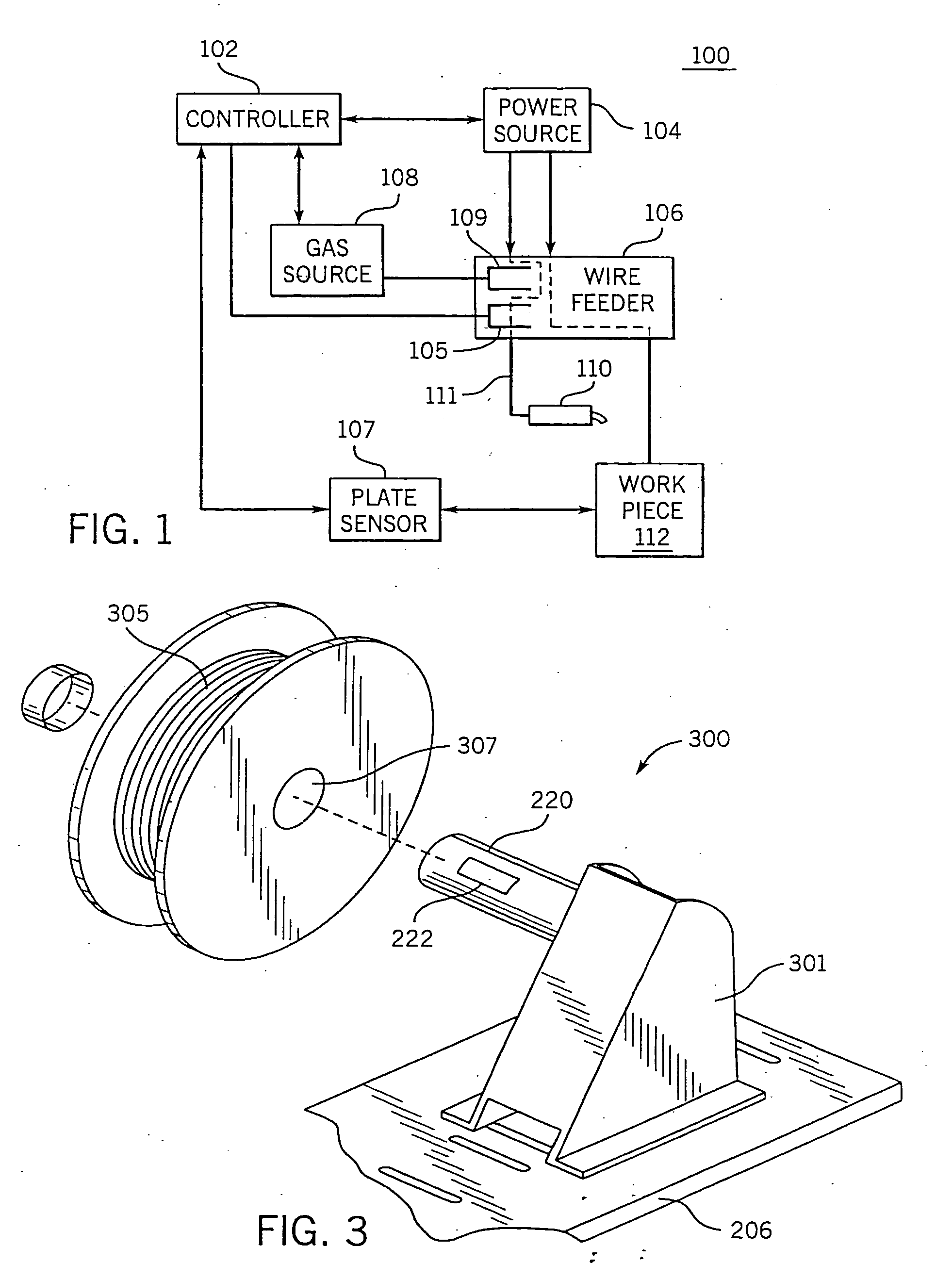

[0017] Referring now to FIG. 1, an inventive welding machine 100 includes a controller 102, a power source 104, a wire feeder 106 and a gas source 108. Also shown is a welding torch 110 and a workpiece 112. Lines connecting the various boxes in FIG. 1 represent connections such as power connections, feedback connections, control connections and gas connections.

[0018] Power source 104 provides weld power to wire feeder 106. Also, gas source 108 provides gas to wire feeder 106. A weld power cable 111 con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com