Method and apparatus for producing molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

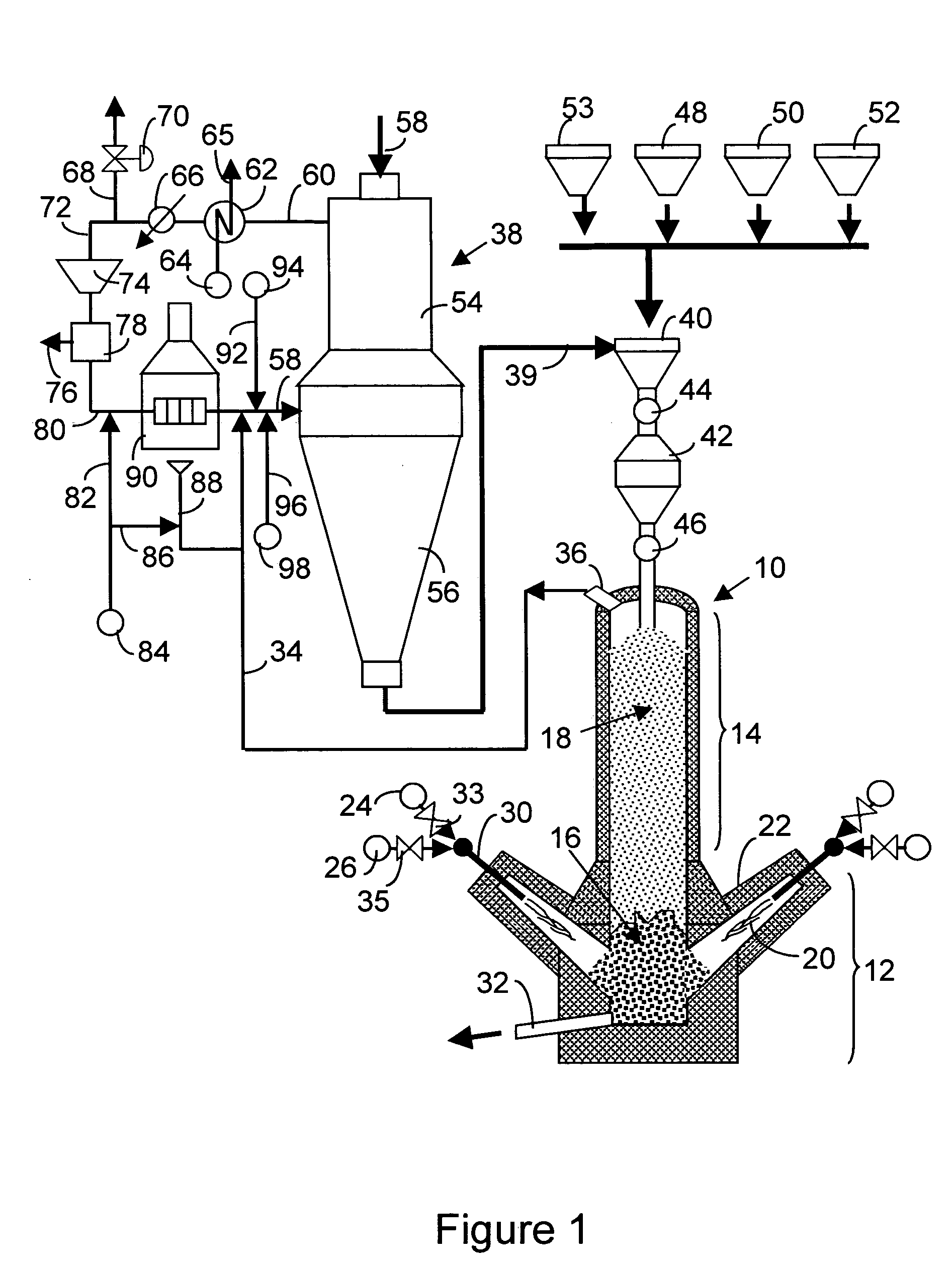

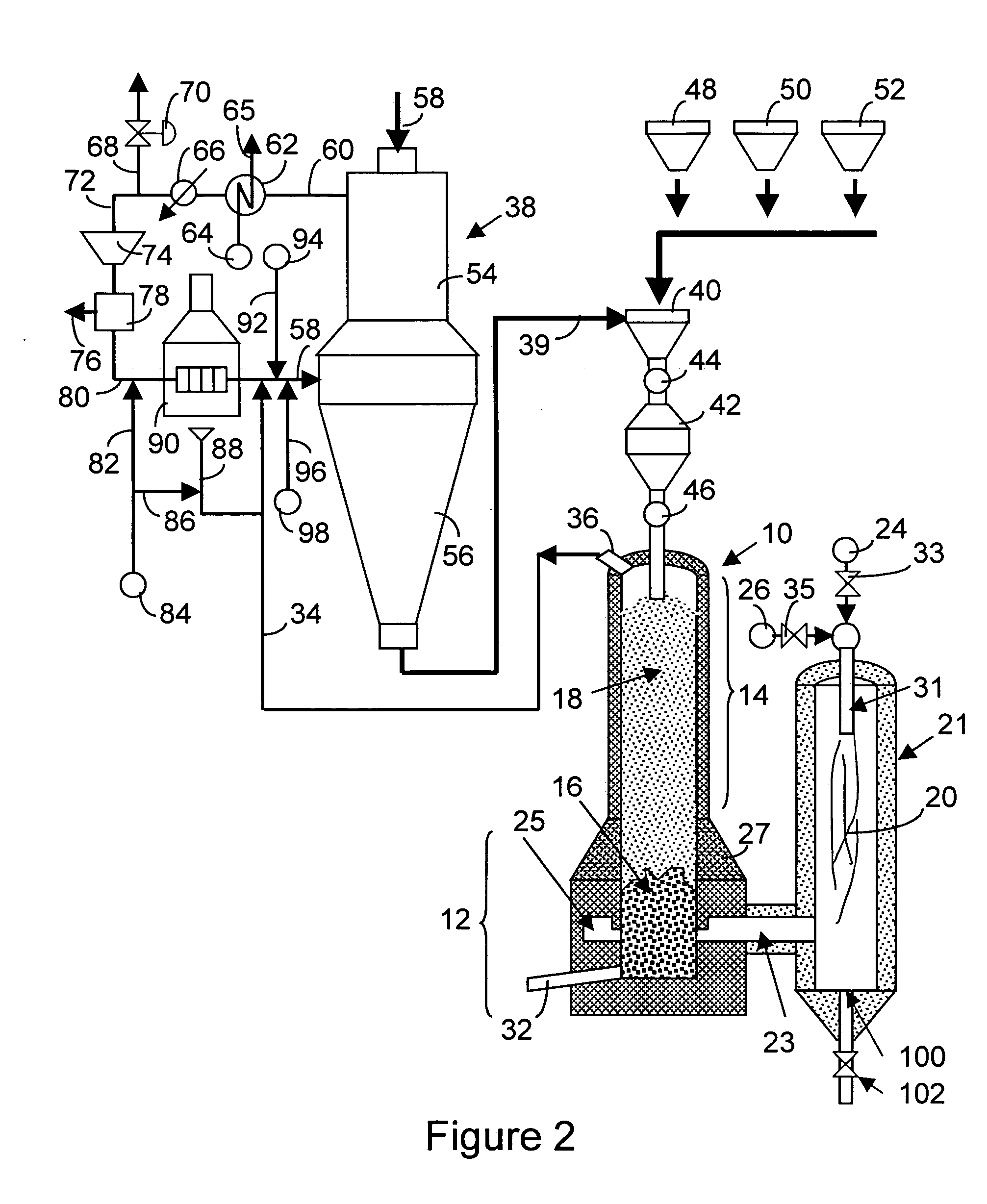

[0029] The present invention will now be described with reference to the Figures. Referring to FIG. 1, a melting furnace 10 having a crucible section 12 and a charging shaft 14 is shown. A bed of coke 16 fills a major portion of the crucible section 12 providing a porous support for a bed 18 of metallic-iron-containing particles which descend through the shaft section 14 as said iron particles melt down. The high-temperature reducing gas 20 produced in a plurality of gas generating zones 22 passes through the coke bed 16 with a composition comprising in its major part hydrogen and carbon monoxide, however, the mixture may contain some carbon dioxide and water, the classic by-products of combustion, and also some methane or other un-burnt fuel. The actual composition of the reducing gases 20 will depend on the type of fuel utilized and will be adjusted to a desired reducing potential value by reacting a fuel 24 and a free oxygen-containing gas 26. Flow rates of fuel and oxygen-gas ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com