Construction residue transport system

a technology for transporting systems and construction residues, applied in the direction of transportation items, packaging, large containers, etc., can solve the problems of large problems, increased concrete being used on these sites, and material becoming extremely slippery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

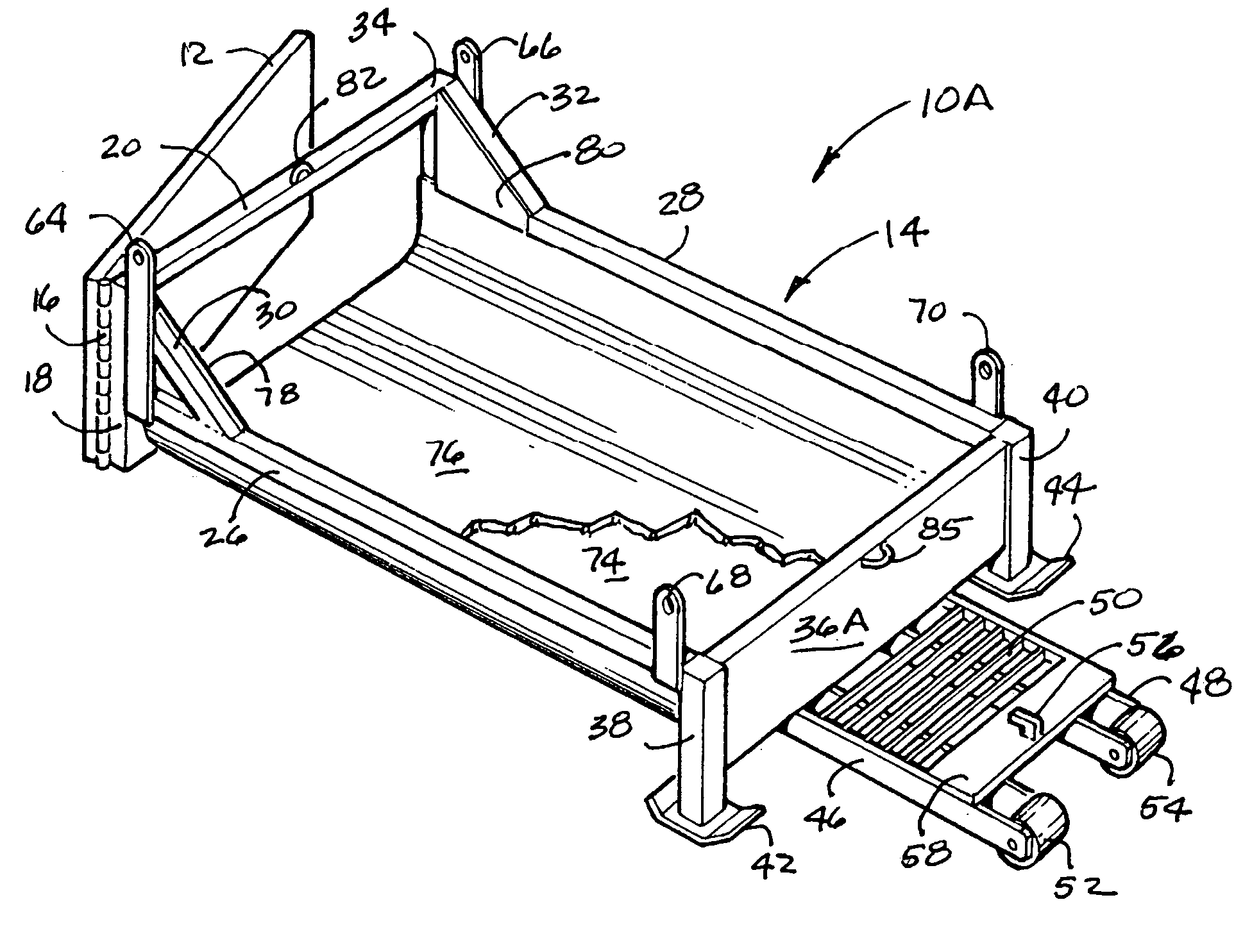

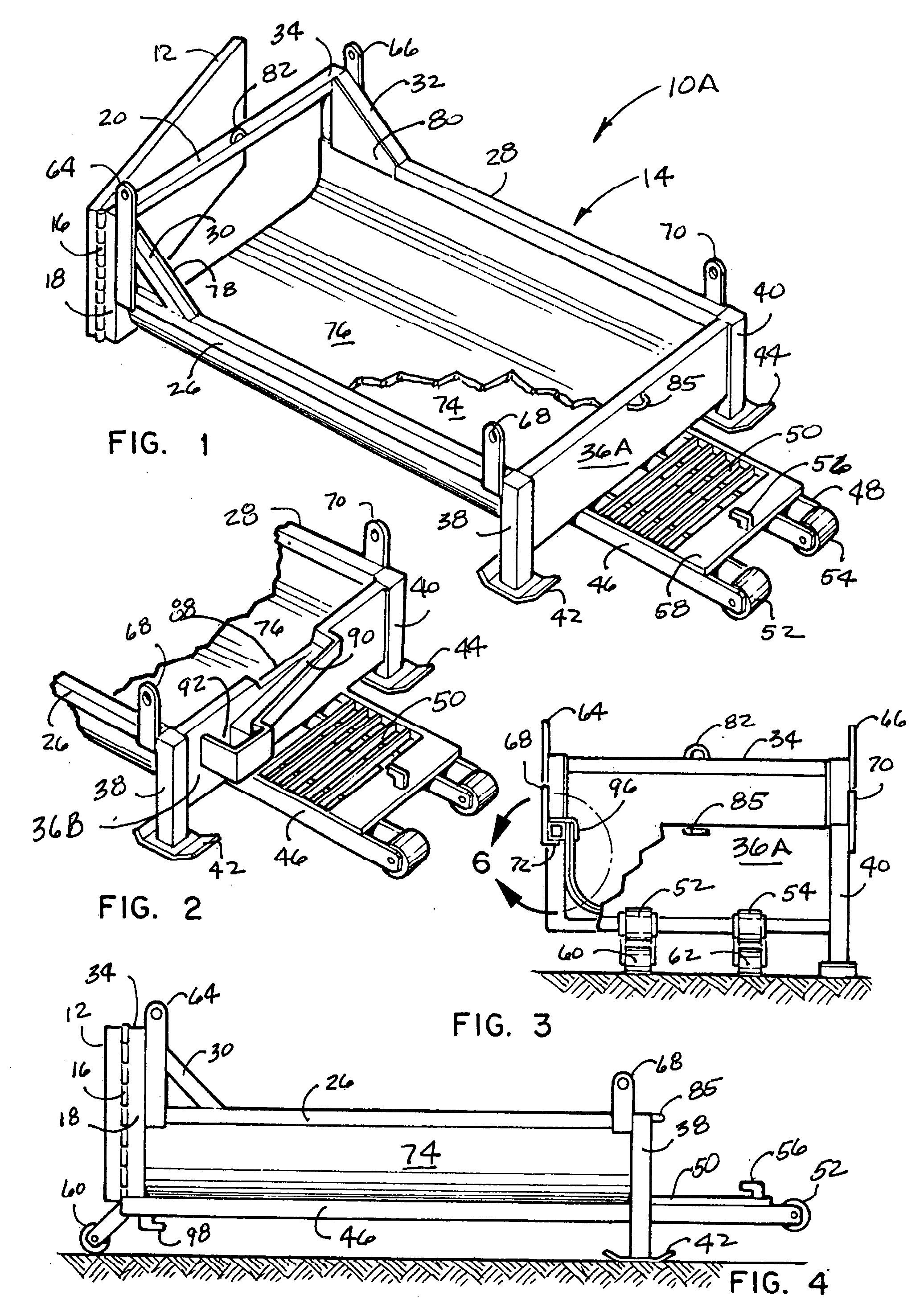

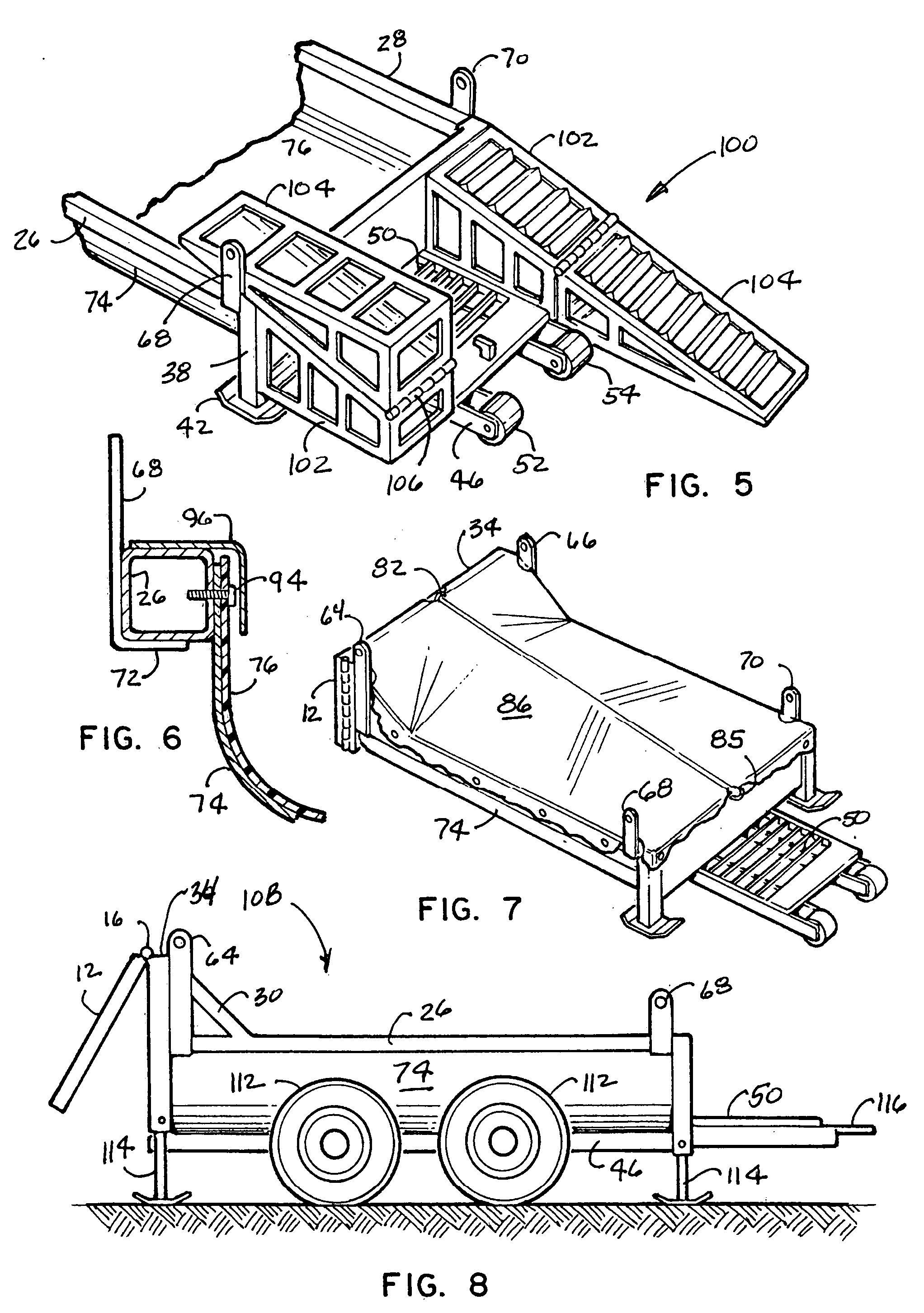

[0047] Referring now to the drawings, wherein similar parts of the invention are identified by like reference numerals, there is seen in FIG. 1 a perspective view of the preferred embodiment of the construction residue transport system 10A with the watertight door or tailgate 12 partially open at the back of the container bed 14. The watertight door or tailgate 12 is shown pivoting from the side by means of a hinge 16. It must be understood that the watertight door or tailgate 12 can pivot from any one of the rear steel side structural members 18 or 22 or the top or bottom steel structural members 20 and 24 attached at the rear of the container bed 14 and still remain within the intent of this patent. The watertight door or tailgate 12 is sealed by means of a typical conventional O-ring seal and toggle clamping mechanism or any other commonly used mechanism in this field. The container bed 14 framework, consists of the rear steel side structural members 18 and 22 along with top and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com