Self-standing bag and method of manufacturing the bag

a self-standing bag and bag body technology, applied in the field of self-standing bags, can solve the problems of reducing the strength of the joining force, reducing the self-standing performance of the bag, and reducing the volume of the bag, so as to improve the self-standing performance and reduce the volume. , the effect of reducing the volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

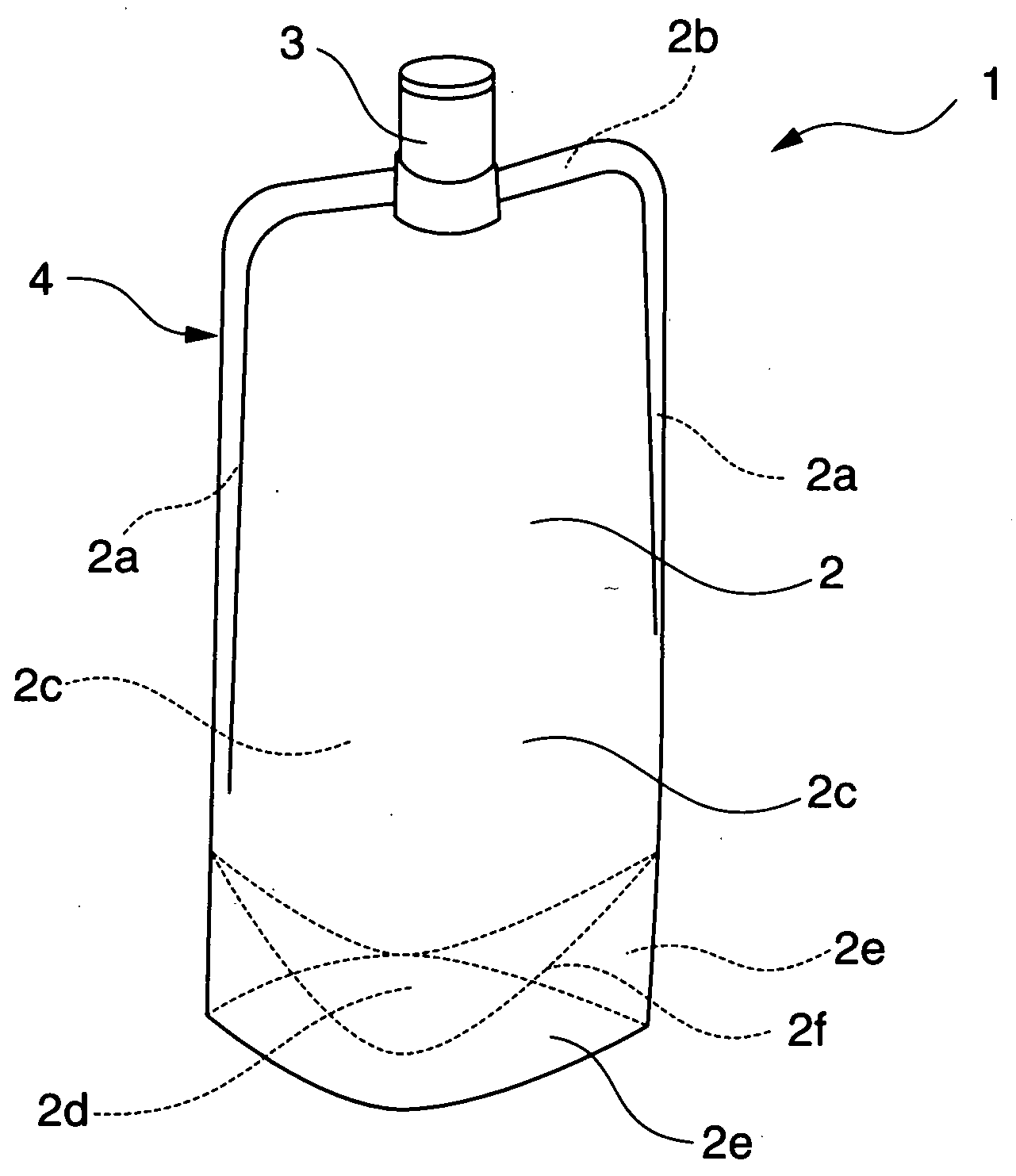

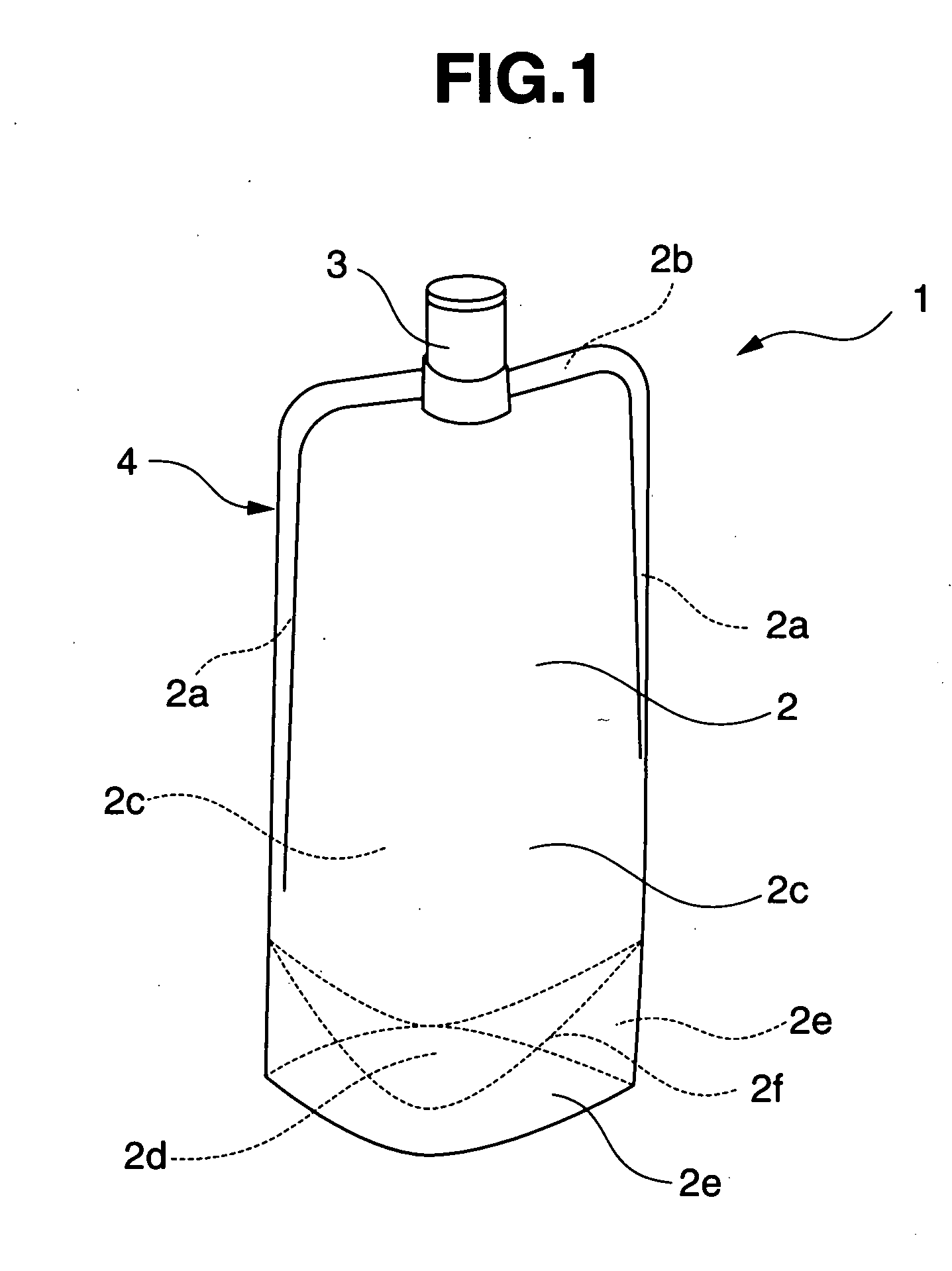

[0016] The present invention will be described more in detail below, referring to the drawings. FIG. 1 illustrates one embodiment of configuration of the self-standing bag according to the present invention, and is a schematic perspective view showing the condition where the self-standing bag 1 is expanded. The self-standing bag 1 has a spout 3 at an upper edge of a bag body 2. A frame 4 having a reverse-recessed shape which is integrally molded with the spout is attached ranging from one side edge 2a through the upper edge 2b to the other side edge 2a so as to clamp the edges 2a, 2b, 2a from the outer sides.

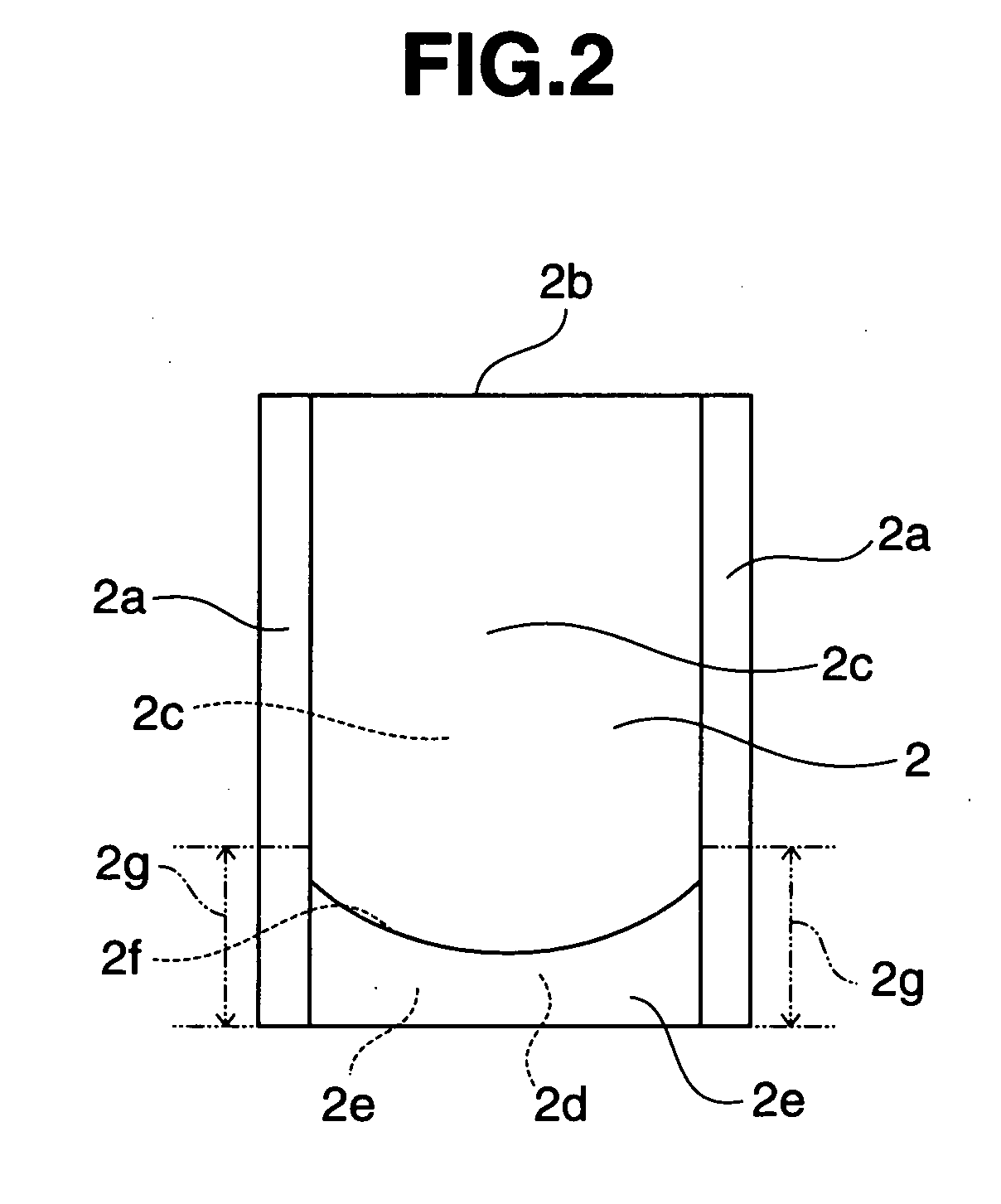

[0017] The bag body 2 is formed by folding an elongate film in four at the lower portion so as to provide two body films 2c, 2c and a bottom film 2d folded down at the bottom portion in a reverse V-shape, then, as will be described later, joining by fusion bonding the side edges 2a, 2a of the body films 2c, 2c, and fusion bonding the folded portion parts in semi-arcuate shapes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com