Method and apparatus for packaging horticultural products

a technology for horticultural products and packaging methods, applied in the field of horticultural products, can solve the problems of increasing shipping costs and distribution time, reducing the life of flowers shipped dry, and reducing the amount of space required during shipping, so as to reduce the amount of space required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

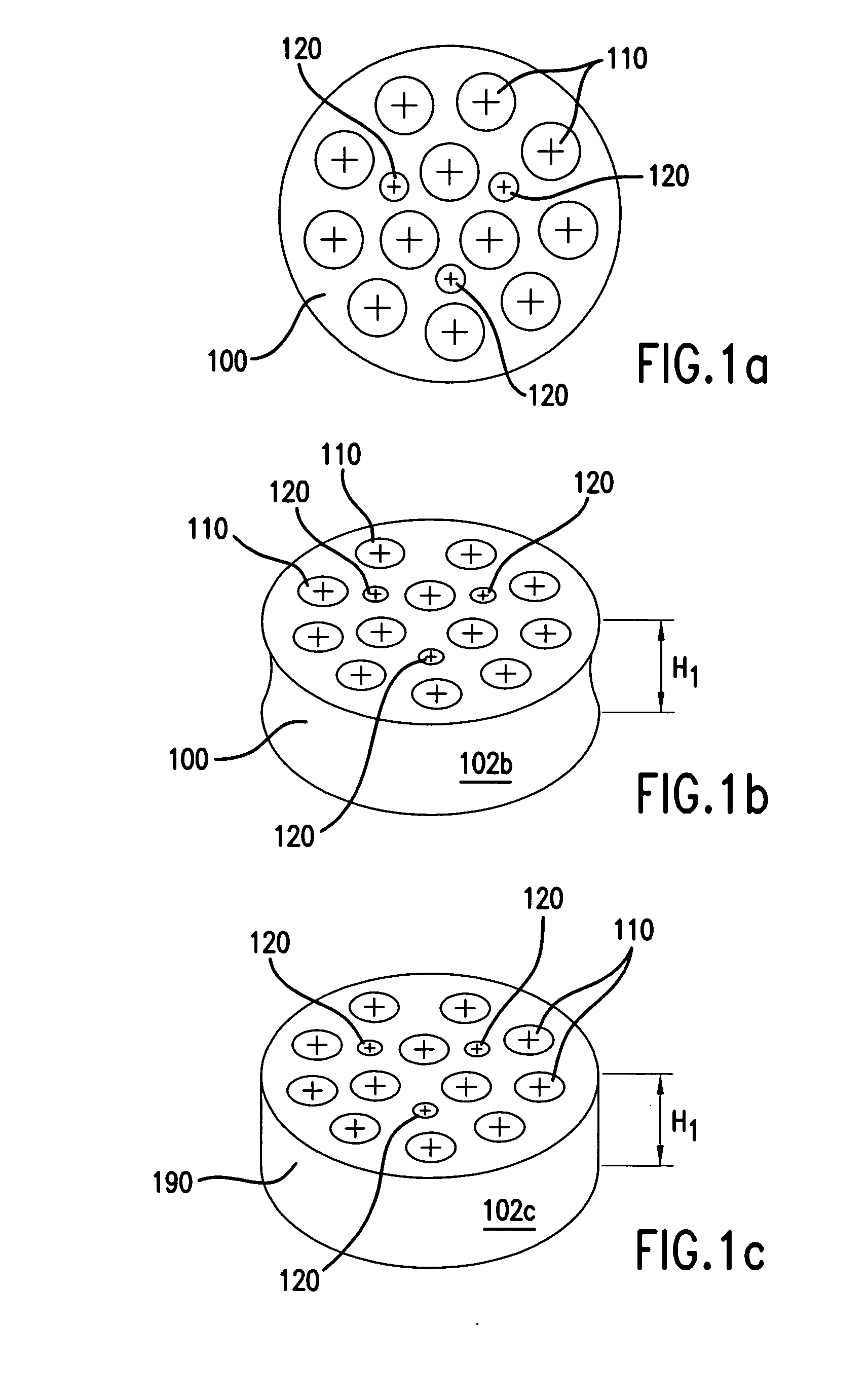

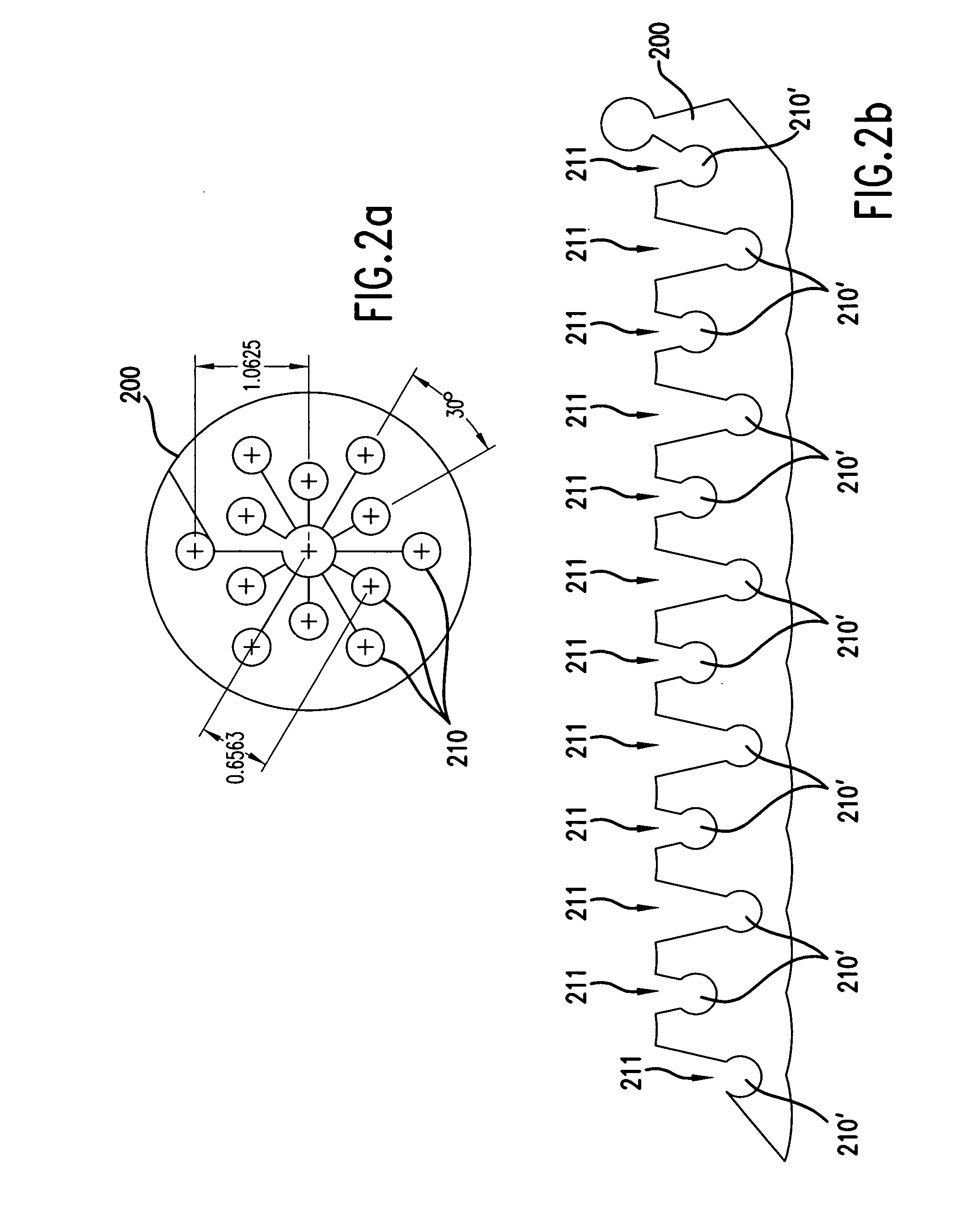

[0050] In the following detailed description, a plurality of specific details, such as types of foam and amounts of compression, are set forth in order to provide a thorough understanding of the present invention. The details discussed in connection with the preferred embodiments should not be understood to limit the present invention. Furthermore, for ease of understanding, certain method steps are delineated as separate steps; however, these steps should not be construed as necessarily distinct nor order dependent in their performance.

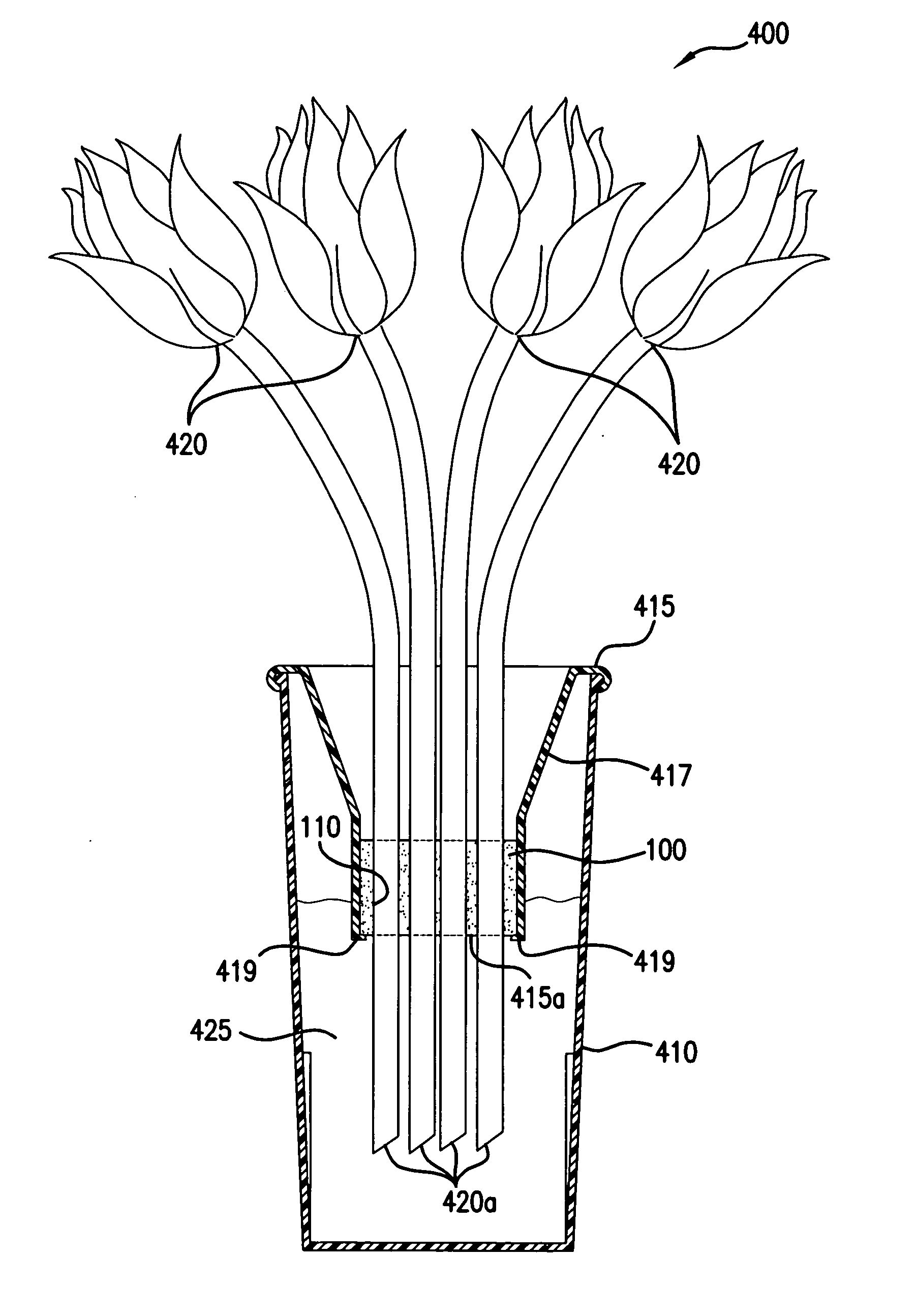

[0051] The invention is believed to have particular utility for the packaging of cut flowers for transportation and hence will be discussed primarily in that context herein. The invention should not be understood to be so limited and should be understood to be useful for packaging horticultural products for other purposes (e.g., display in a retail setting) and should also be understood to be useful with other horticultural products such as potted p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com