Pixel based machine for patterned wafers

a pixel-based machine and wafer technology, applied in the field of surface inspection of semiconductor wafers, can solve the problems of inability or useless further operation, and achieve the effect of shortening processing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

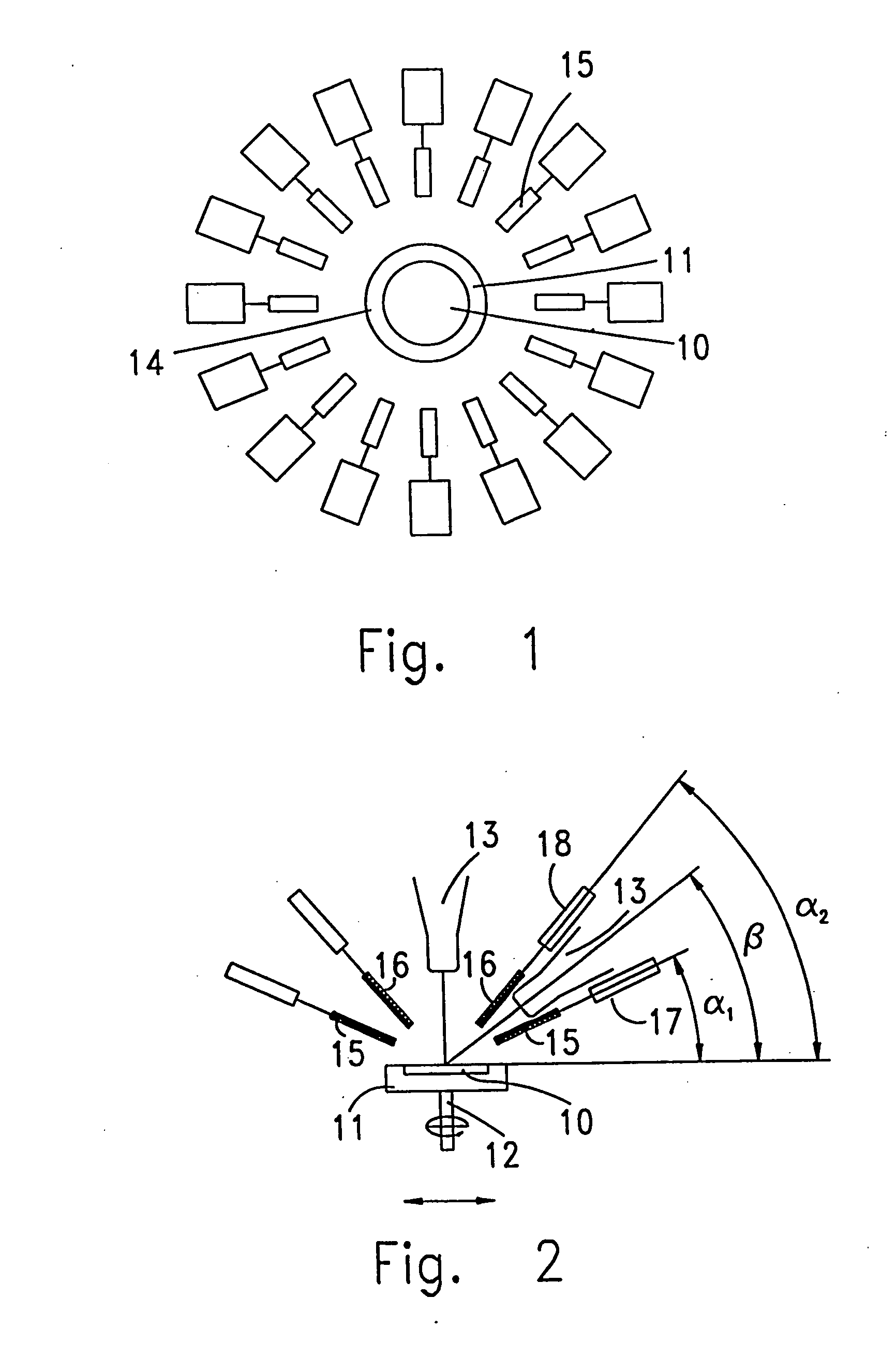

[0115]FIGS. 1 and 2 schematically represent an apparatus according to an embodiment of the invention. Numeral 10 indicates a wafer that is being inspected. The apparatus used for the inspection comprises a stage having a wafer support. The wafer is placed on said support, which in this embodiment is a support plate 11, which is rotated about shaft 12 by mechanical means, not shown as being conventional. A laser source is shown at 13 in its central position, above the axis of shaft 12. However, more than one source could be provided and any source could be placed at an angle to the axis of shaft 12, to provide the required illumination of the wafer, depending on the type of wafer under inspection. In FIG. 2 one such additional laser source is shown, by way of illustration, oriented at an angle β from the plane of the wafer. Mechanical means, not shown as being conventional, translate the shaft 12, viz. shift it, while maintaining it parallel to itself, so that any point thereof moves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com