Collapsible container

a container and lid technology, applied in the field of molded plastic containers, can solve the problems of substantial leakage and inability to use other than as temporary drinking containers, and achieve the effect of not being practical in the field of collapsible containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

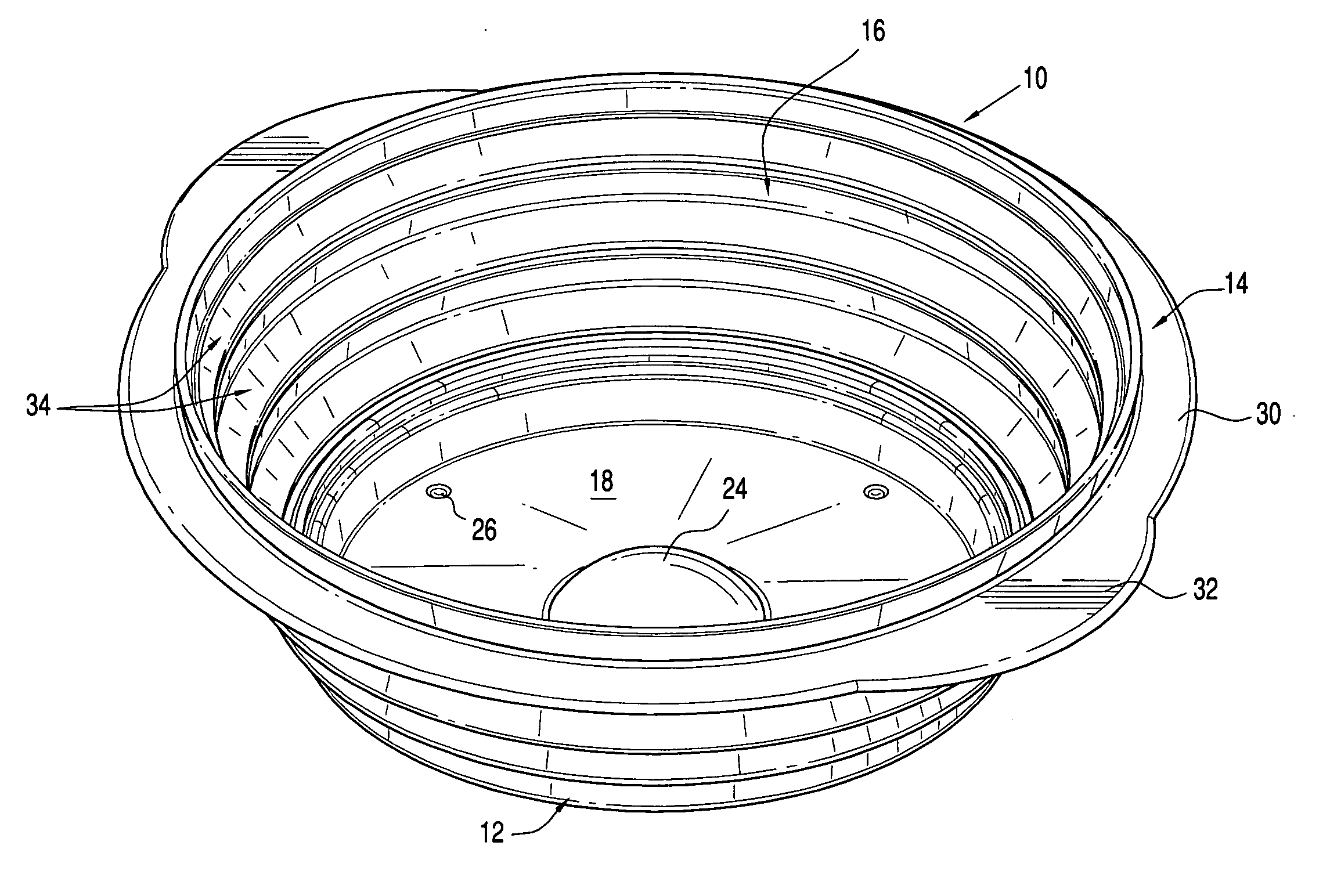

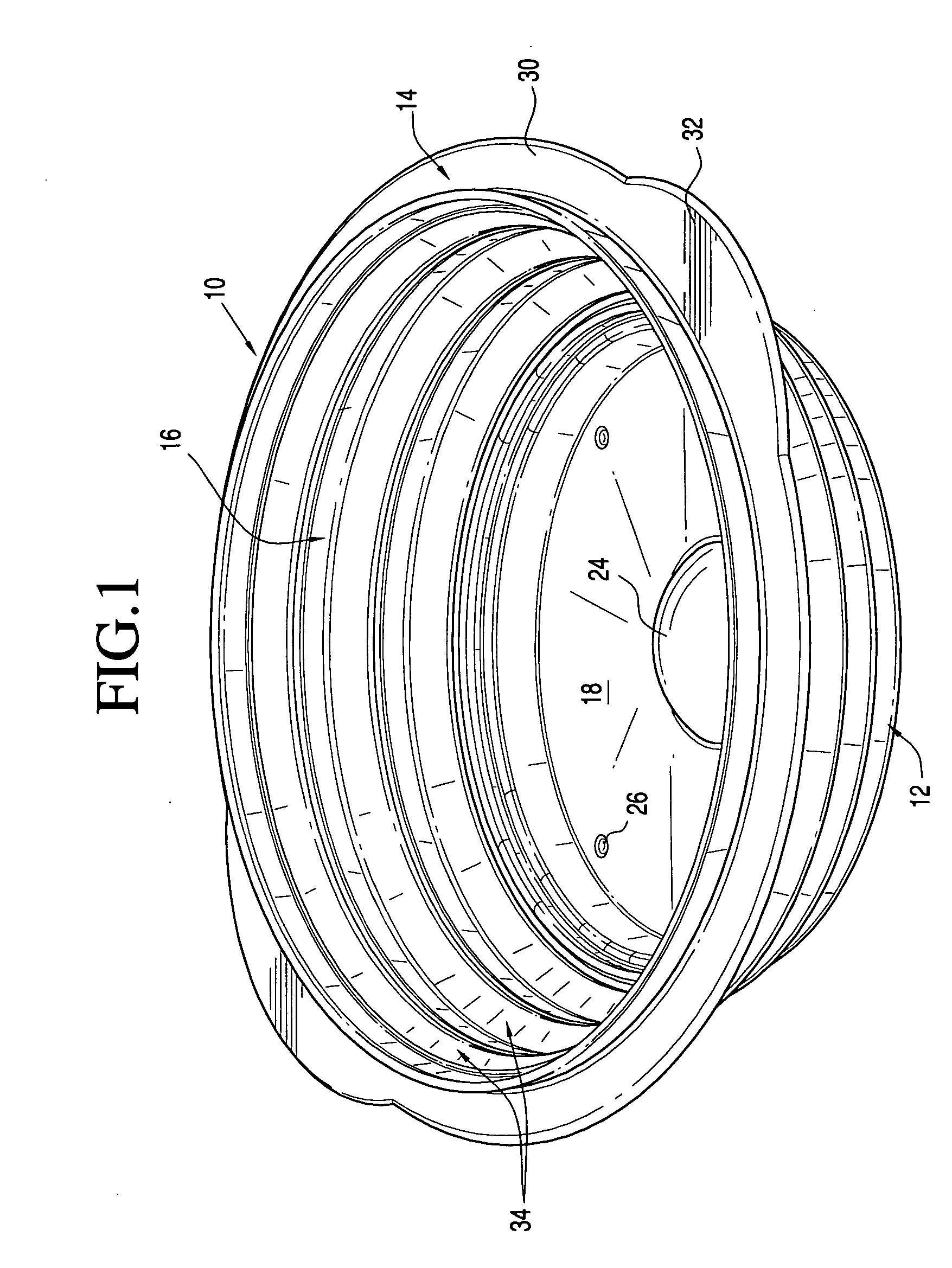

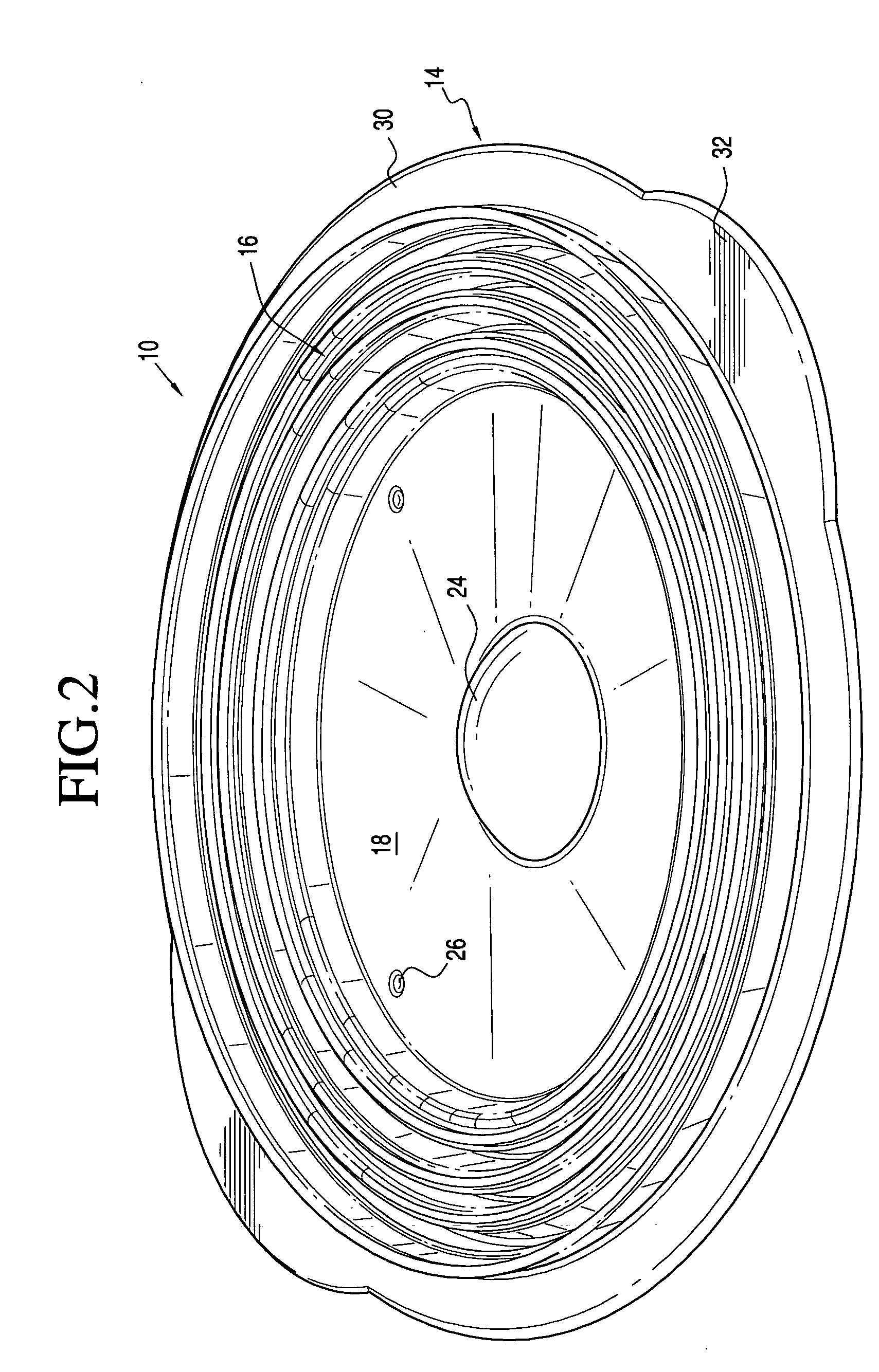

[0025] In the drawings, the features of the embodiment of FIGS. 1-11 are referred to by two digit numbers. Similar features in the embodiment of FIGS. 12-22 are referred to by the same numbers with the number 1 as a prefix.

[0026] Referring now more specifically to the drawings, the collapsible container 10 comprises a base 12, a top ring 14 and a folding wall 16 extending therebetween. The base 12 is a substantially rigid member including a bottom 18 with a peripheral upstanding base wall 20. The base, which may be flat, preferably includes a central slightly upwardly extending pressure area or bump 24 of any appropriate configuration, such as a dome, to assist in expanding the container as shall be described subsequently. The base will also preferably have a series of small foot defining knobs 26 or a continuous foot rib, not shown, depending from the base bottom 18.

[0027] The top ring 14 includes a continuous or annular ring wall 28 with a peripheral horizontally outwardly direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com