Chain cutter

a chain cutter and chain cutting technology, applied in the field of chain cutting apparatus, can solve the problems of reducing the cutting efficiency of the chain cutter, so as to reduce the time, energy and equipment required, and the effect of reducing the physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

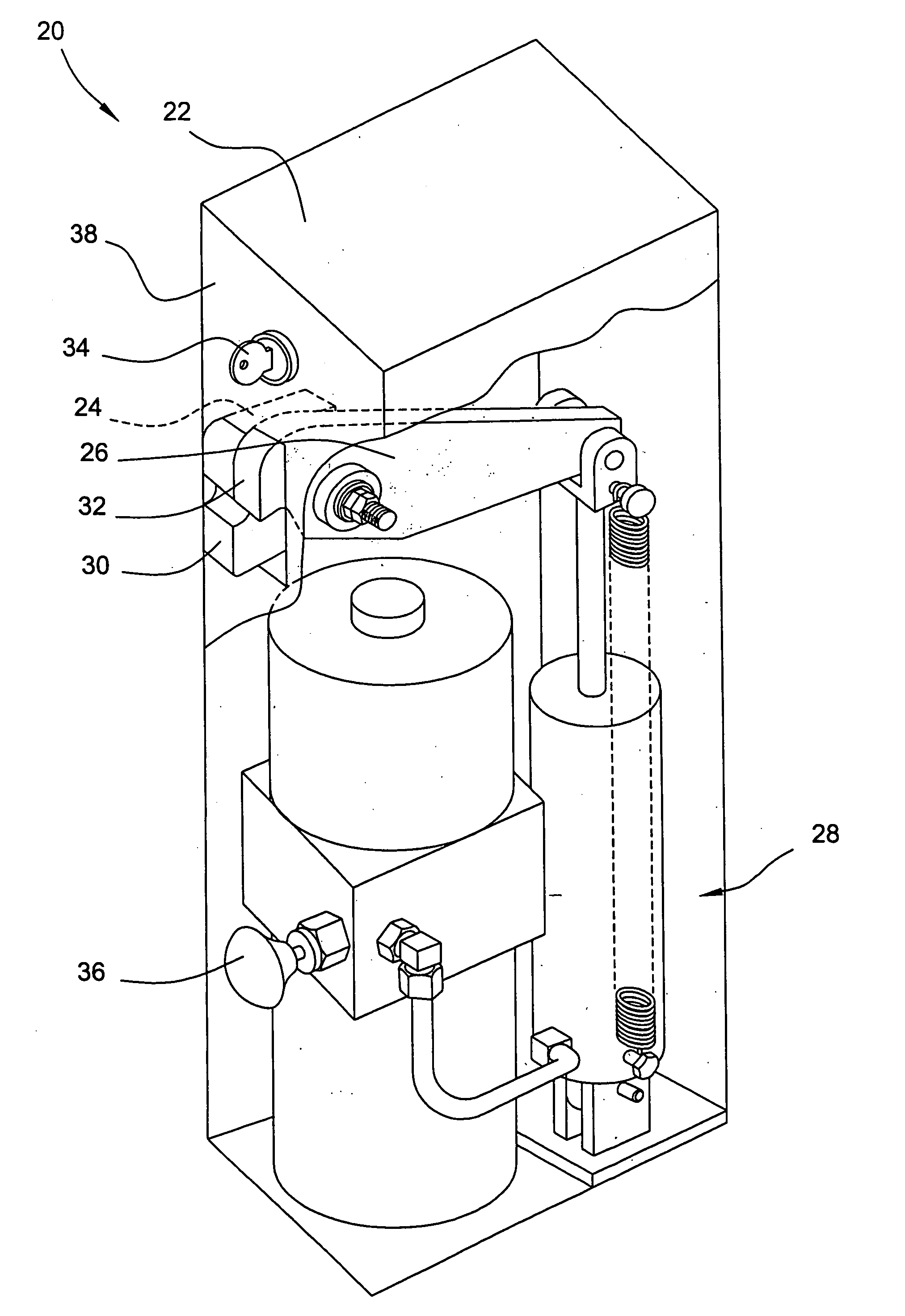

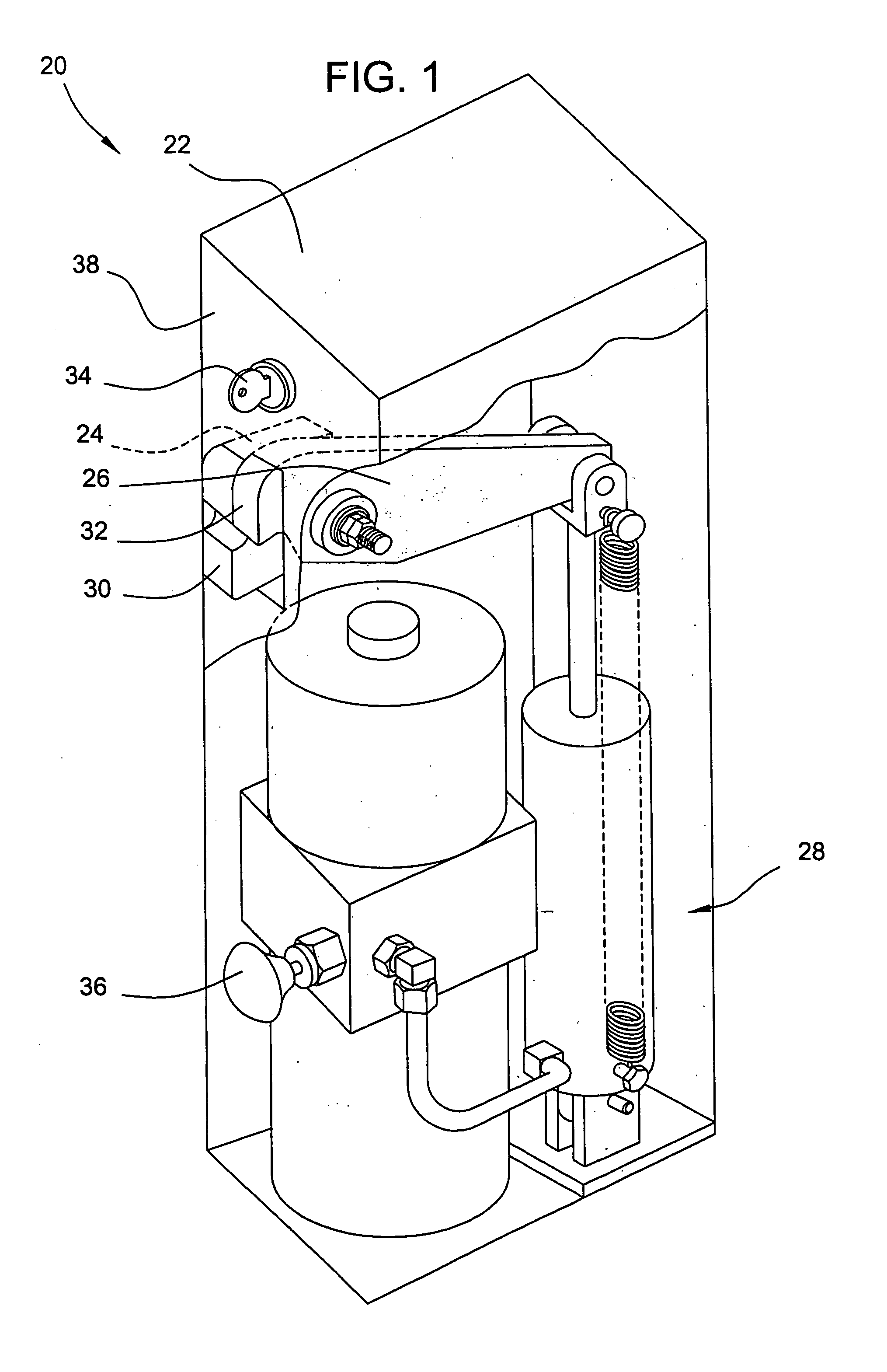

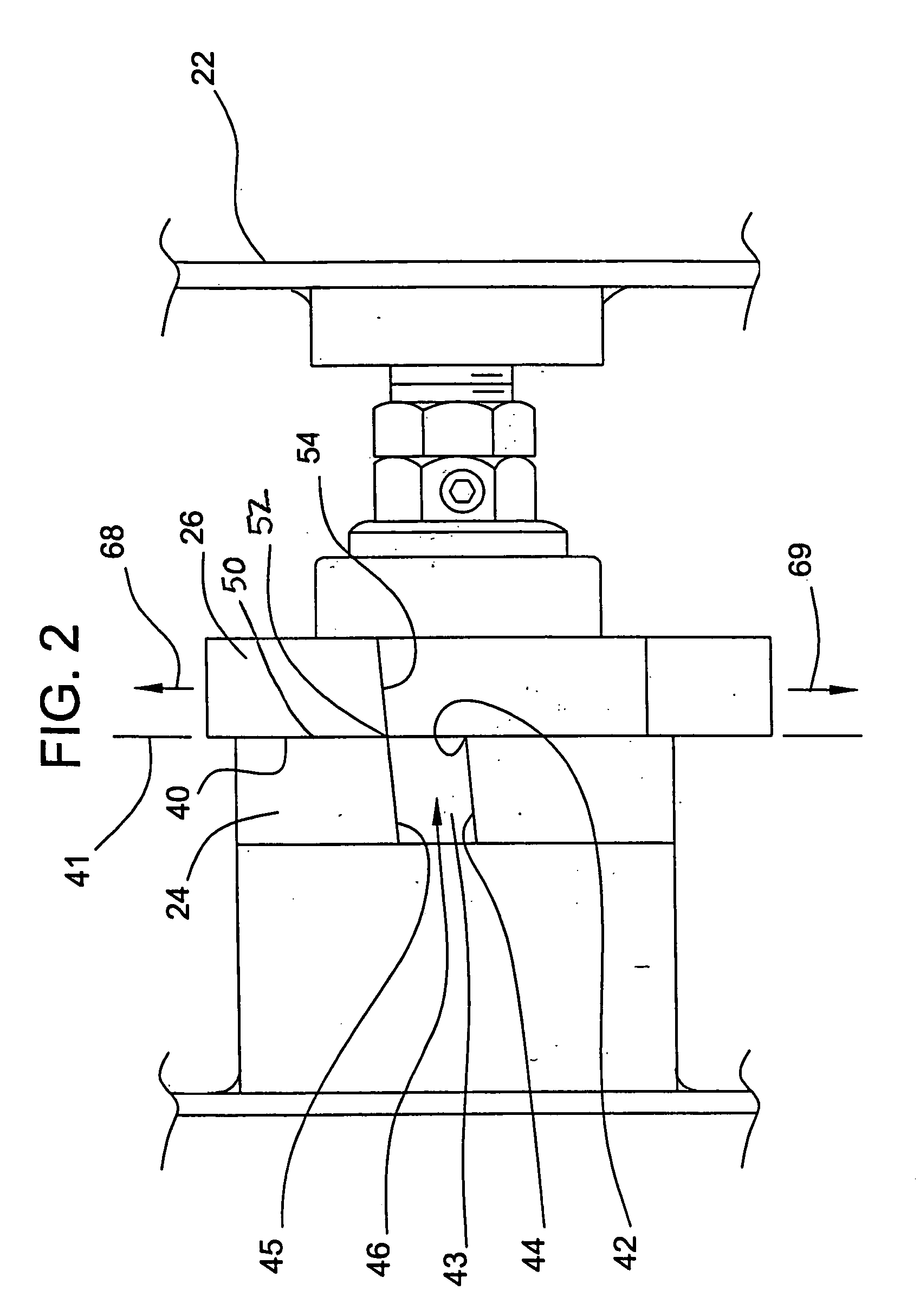

[0032] Shown in the drawings is an illustrative apparatus for cutting and opening chain links and bolts and for severing steel wire sold, for example, in hardware stores and material supply depots. The illustrative chain cutter shown herein improves upon and solves some of the drawbacks associated with the chain cutter shown and described in U.S. Pat. No. 3,996,782, filed Jul. 17, 1975, and entitled “Chain Cutting Apparatus,” which is incorporated herein in its entirety by reference.

[0033] The instant apparatus employs a pair of shearing members which interact to first shear a link of chain at a point along its circumference and then to bend the link. The latter operation of opening the link to permit the disengagement of the severed link is more efficient, energy wise, than generating a second cut to facilitate removal of the link. To allow a wide range of operators to use the chain cutting apparatus, an automatic actuator system is provided to operate automatically at least one o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rake angle | aaaaa | aaaaa |

| rake angle | aaaaa | aaaaa |

| jaw angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com