Forming apparatus and method for constructing concrete columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

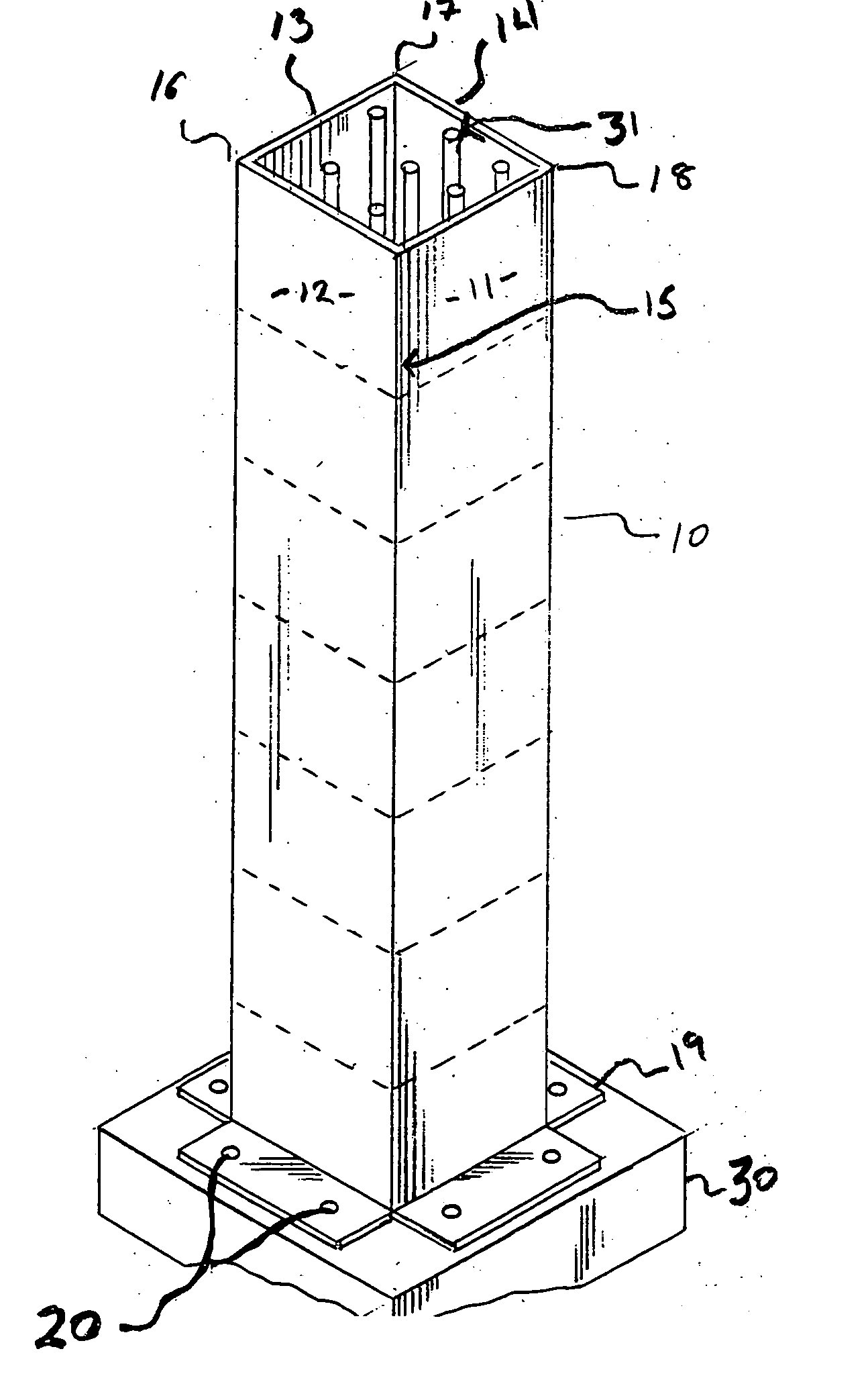

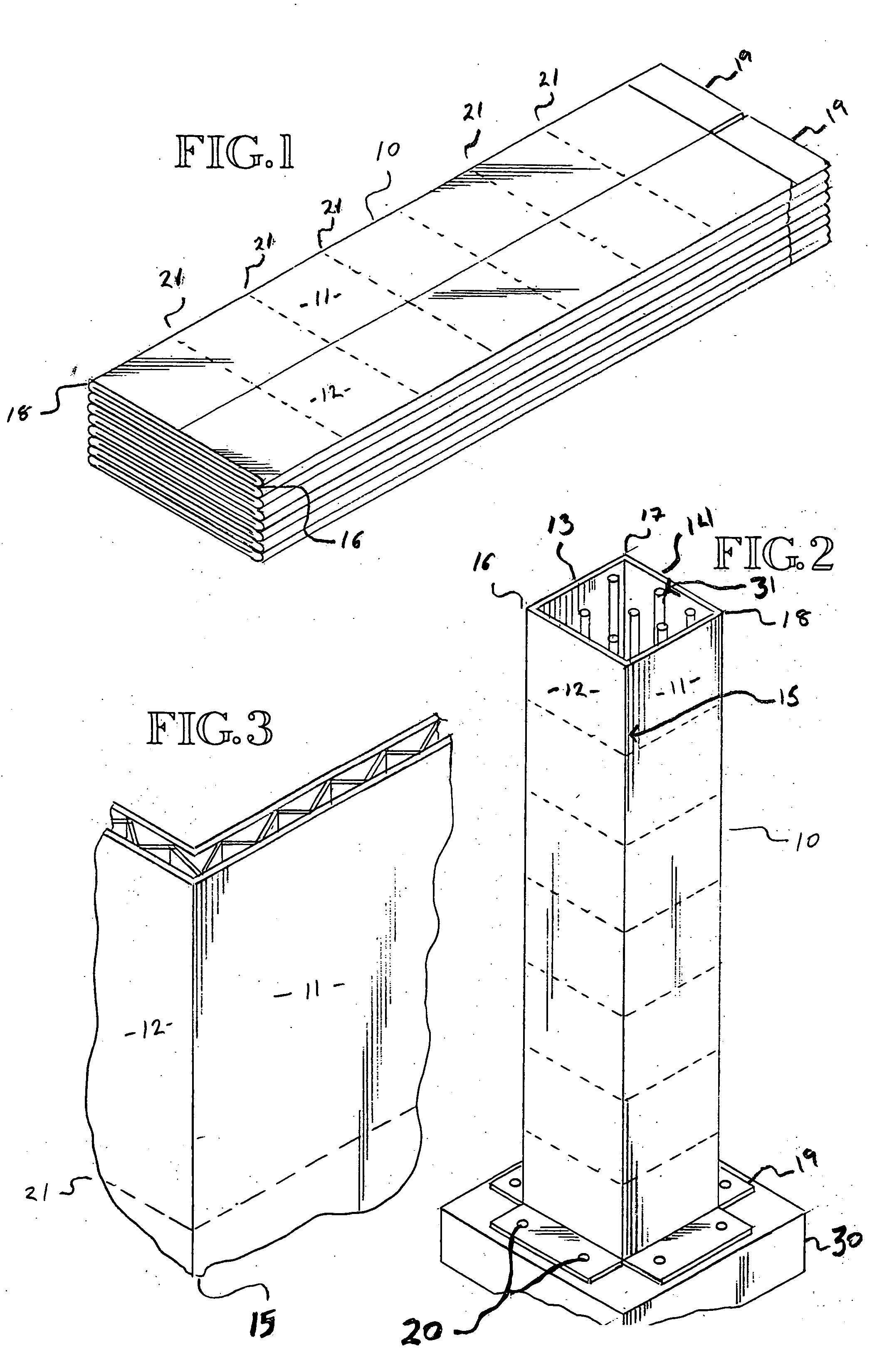

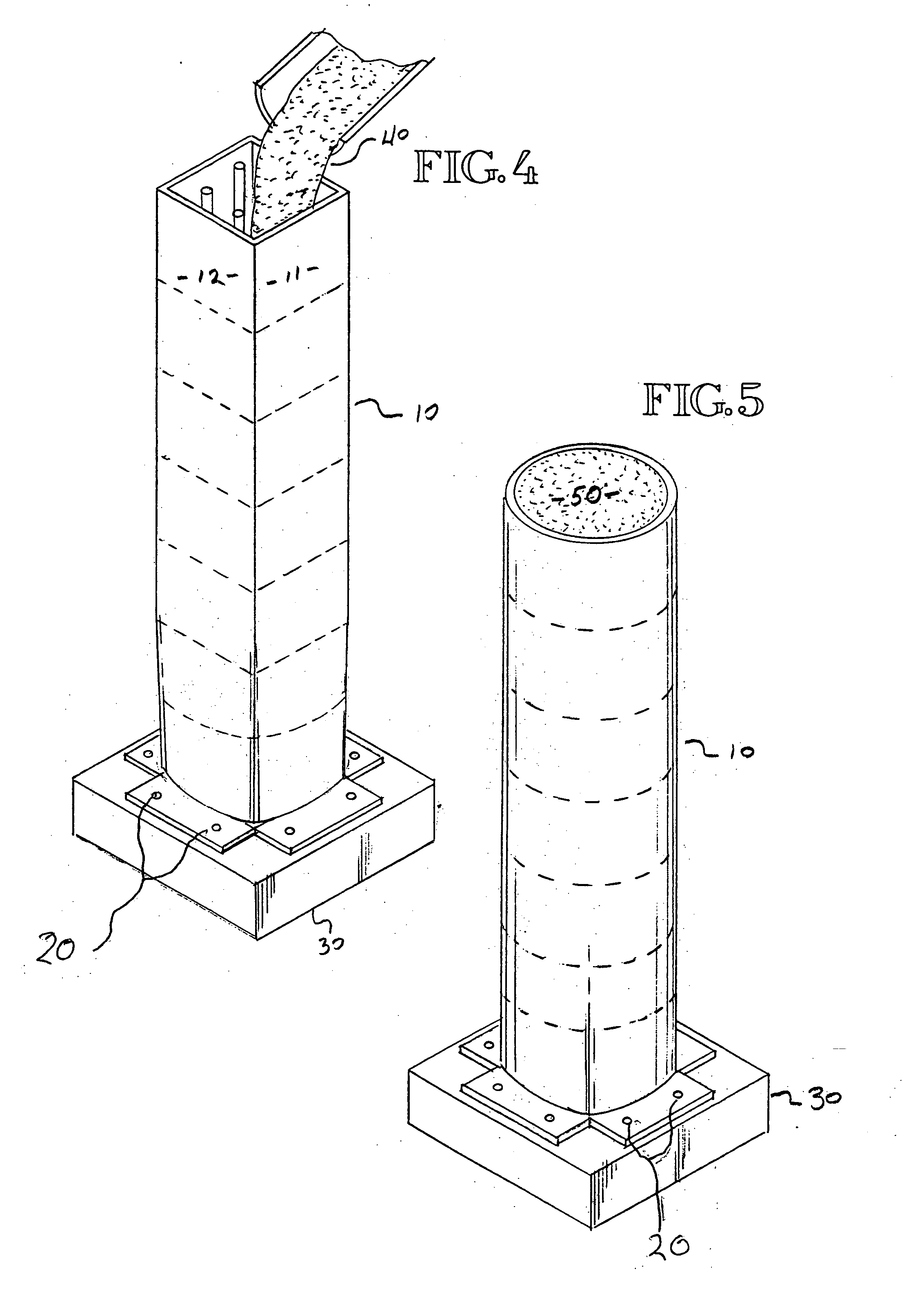

[0022] Turning now to the drawings, the invention will be described in a preferred embodiment by reference to the numerals of the drawings wherein like numbers indicate like parts.

[0023]FIG. 1 shows a preferred embodiment of the pier / column form disclosed herein wherein several forms 10 are folded and stacked for storage or transportation to a construction site. As can be seen in FIG. 2 and FIG. 3, the forms disclosed herein are constructed from corrugated plastic and have four side walls that define an elongated form with an interior for the placement of concrete, and having a generally square cross sectional shape when viewed from above.

[0024] In at least one preferred embodiment, the form is constructed from a single piece of corrugated plastic that has a plurality of seams / folds, which define the corners of the form. The free edges of the sheet of corrugated plastic can be overlapped and connected with an adhesive such as construction glue of the like or other connection means...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com