Dry safety device for an inflammable gas

a safety device and inflammable gas technology, applied in dental surgery, lighting and heating apparatus, combustion types, etc., can solve the problems of dangerous condition, dry safety device not functioning, safety device not constructed to prevent the counter flow of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

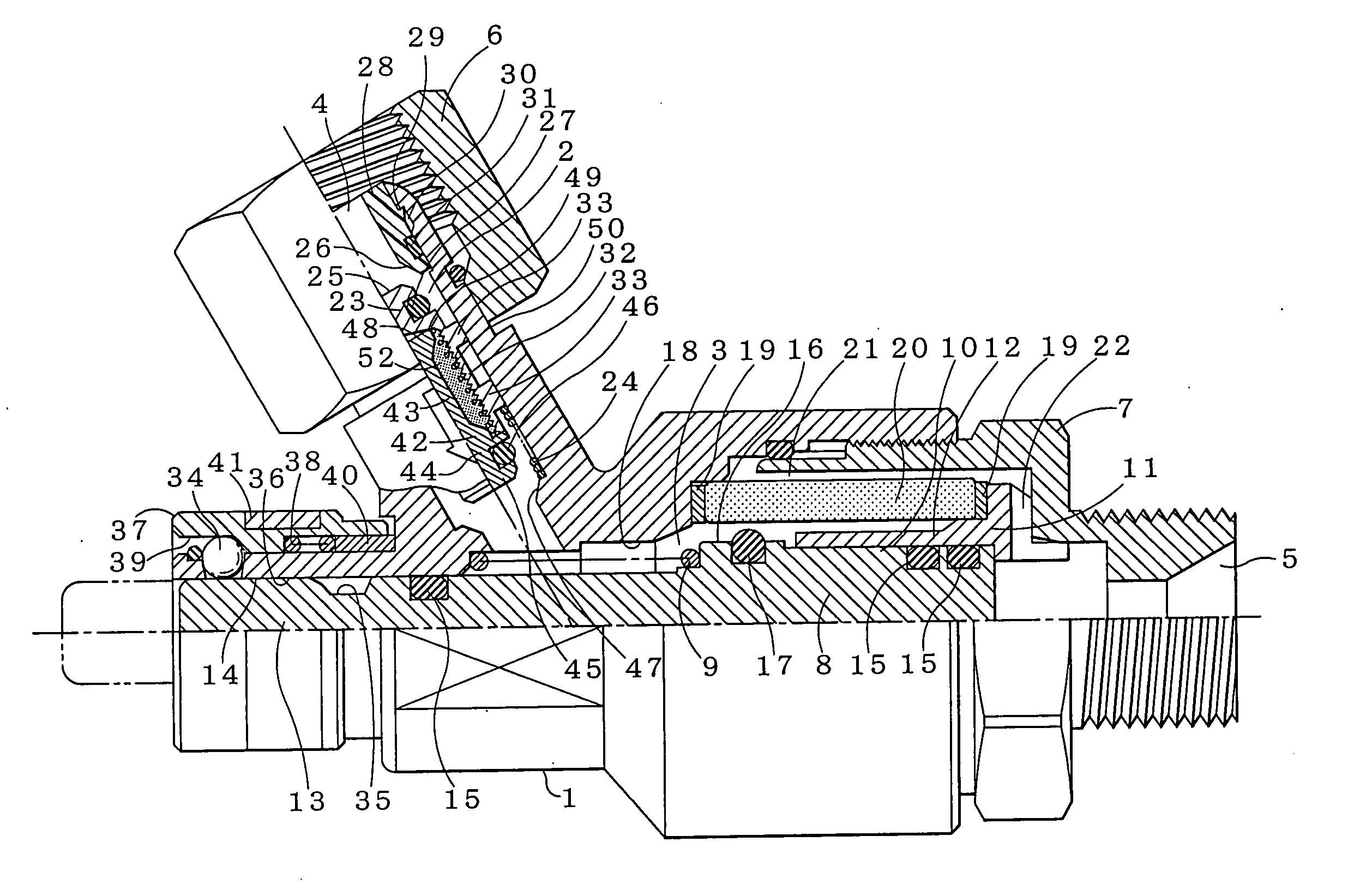

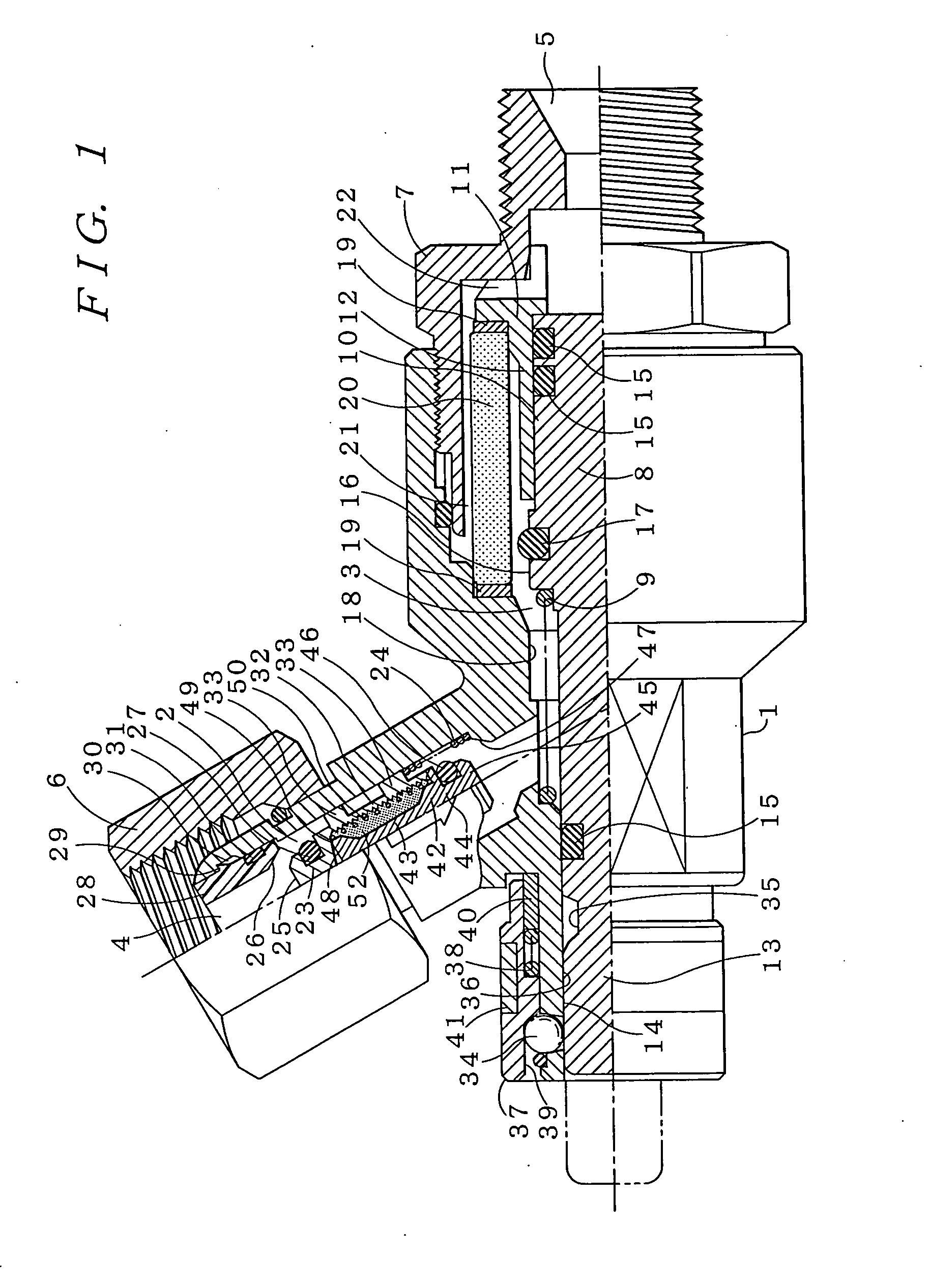

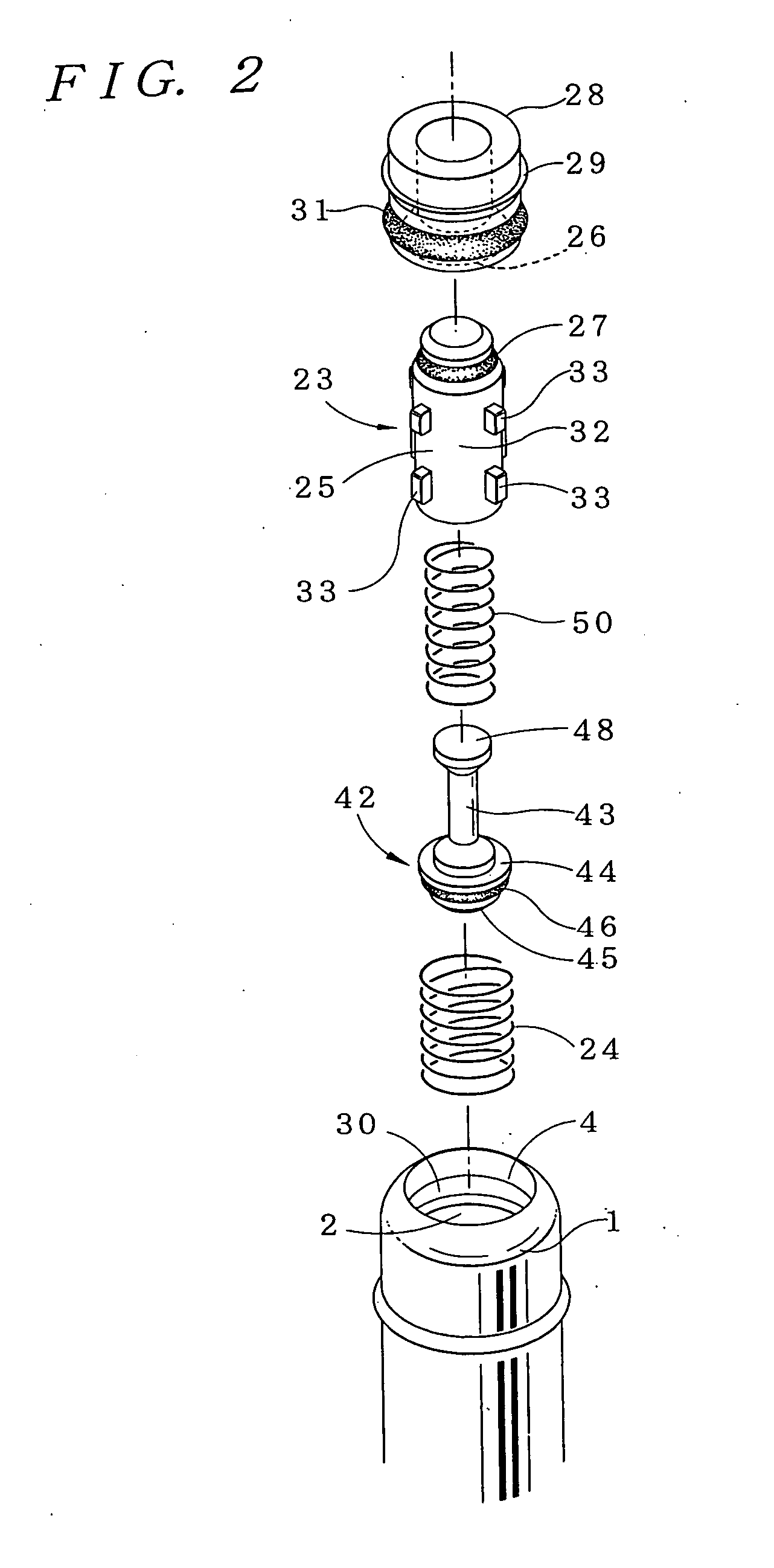

[0016]FIG. 1 shows an embodiment of a dry safety device for an inflammable gas according to the present invention. The dry safety device has a case main body (1) having therein a gas passage comprised of a first passage (2) and a second passage (3) which extends in a direction crossing the first passage (2). The first passage (2) has an inlet end terminating in a primary side open port (4) for connection to a supply source of inflammable gas, and the second passage (3) has an outlet end terminating in a secondary side open port (5) for connection to a burner torch. Around the primary side open port (4) of the case main body (1), a cap nut (6) is provided for detachable connection to a hose or the like which communicates to a source of pressurized inflammable gas, such as a bomb (not shown). On the secondary side of the case main body (1), a secondary side main body (7) having the secondary side open port (5) is screwed, and a secondary side gas-fired appliance such as a burner torch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com